F00633 Page 3

General Information

Installation

FOUNDATION: Refer to illustration on Page 4.

Heavy weights; risk of bodily harm due

to crushing. Use care and proper lifting equipment

when handling pump for installation. Size and weight of

some units will require hoists for safe handling.

Pump should be set on a concrete foundation which is

sufficiently substantial to absorb vibration and which

provides a permanent and rigid support.

When properly positioned, the unit will be level, and the

suction and discharge openings of the pump will be

aligned with system piping.

PIPING:

System piping should be at least one commercial pipe

size larger than pump connections and flow velocity

should not exceed eight (8) feet per second. Suction and

discharge pipes must be naturally aligned with pump

connections.

NOTICE: Misalignment of piping with pump case or

excessive pipe strain can cause distortion of pump

components resulting in rubbing, breakage and reduced

pump life.

Insure that piping is supported in a manner that prevents

the exertion of force on pump connections. This can be

checked by the following procedure. With the pump shut

down, remove pipe flange bolts. If the mating flanges

come apart or shift, misalignment is present and causing

pressure on the connections. Adjust pipe supports until

flanges mate without any force. This procedure can be

done throughout piping system.

SUCTION PIPING:

Refer to illustrations on Page 8 through Page 11 for

recommended and not recommended practices in

suction connections.

DISCHARGE PIPING:

Refer to illustrations on Pages 12 through 13 for

recommended and not recommended practices in

discharge connections.

ELECTRICAL CONNECTION:

If electric motor is used.

NOTE: All wiring should be done by a qualified

electrician.

Hazardous voltage. Can shock, burn, or

cause death. Disconnect power to pump before

servicing.

Check voltage and phase stamped on pump motor

nameplate before making wiring connections to

electrical system. Be sure they agree with your electric

current supply. They MUST be the same. If in doubt,

check with your local power company.

Refer to illustration on Page 7 for minimum recom-

mended pumping panel components that help safeguard

your pump during operation.

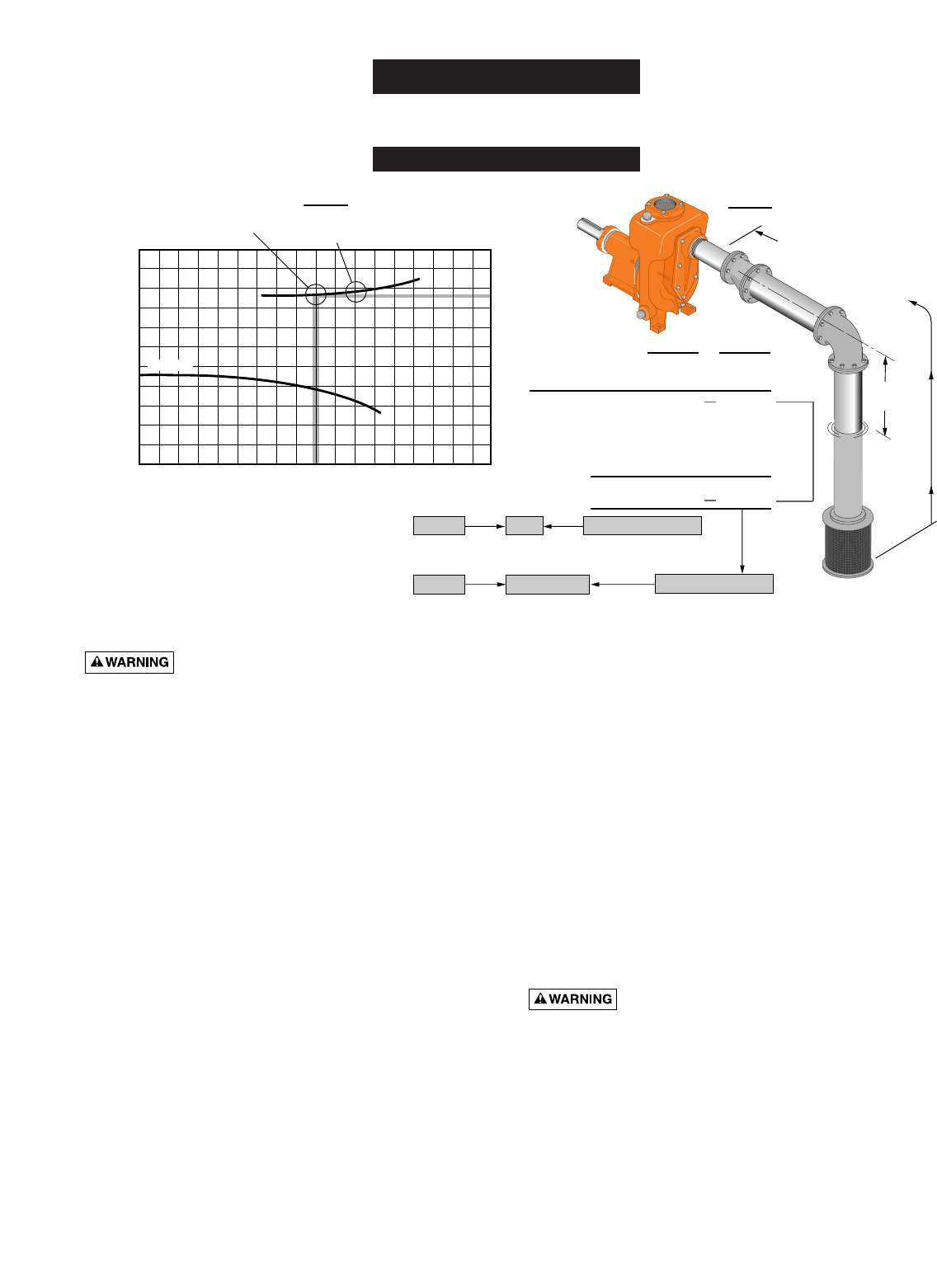

EXAMPLE

ONLY

NPSHR

A Model B4ZRKS operating at 450 GPM

with 95 Feet of Head has a NPSHR of.......... 8 Feet

at that point on the performance curve.

A Model B4ZRKS operating at 550 GPM

with 85 Feet of Head has a NPSHR of.......... 9 Feet

at that point on the performance curve.

NPSHA = 9.5 Feet

OK

NPSHA = 8.5 Feet

CAVITATION

Static Lift = 9.0 Feet 9.0 Feet

10.5 Feet

19.5 Feet

19.5 Feet

Theoretical static

lift of centrifugal

pump at sea level =

Total = 18.5 Feet

Total Friction Loss = 9.5 Feet

Safety Factor - 6.0 Feet

Minus 18.5 Feet

Practical Limit = 28.0 Feet 28.0 Feet

34.0 Feet

450 GPM 550 GPM

2111 1095

9 Feet

Static Lift

9.5 Feet total friction loss

@ 450 Gallons per minute.

10.5 Feet total friction loss

@ 550 Gallons per minute.

0 100 200 300 400 500 600 700

0

50

100

150

TDH

Gallons Per Minute

0

10

20

30

NPSH in Feet

B4ZRKS

NPSHR at this point

= 8 Feet

NPSHR at this point

= 9 Feet

NPSHA

2000 RPM

FIGURE 1