7

Form 6104 BCF5-R0301

Instruction Manual – Model CF500/CF800 Oil Burner

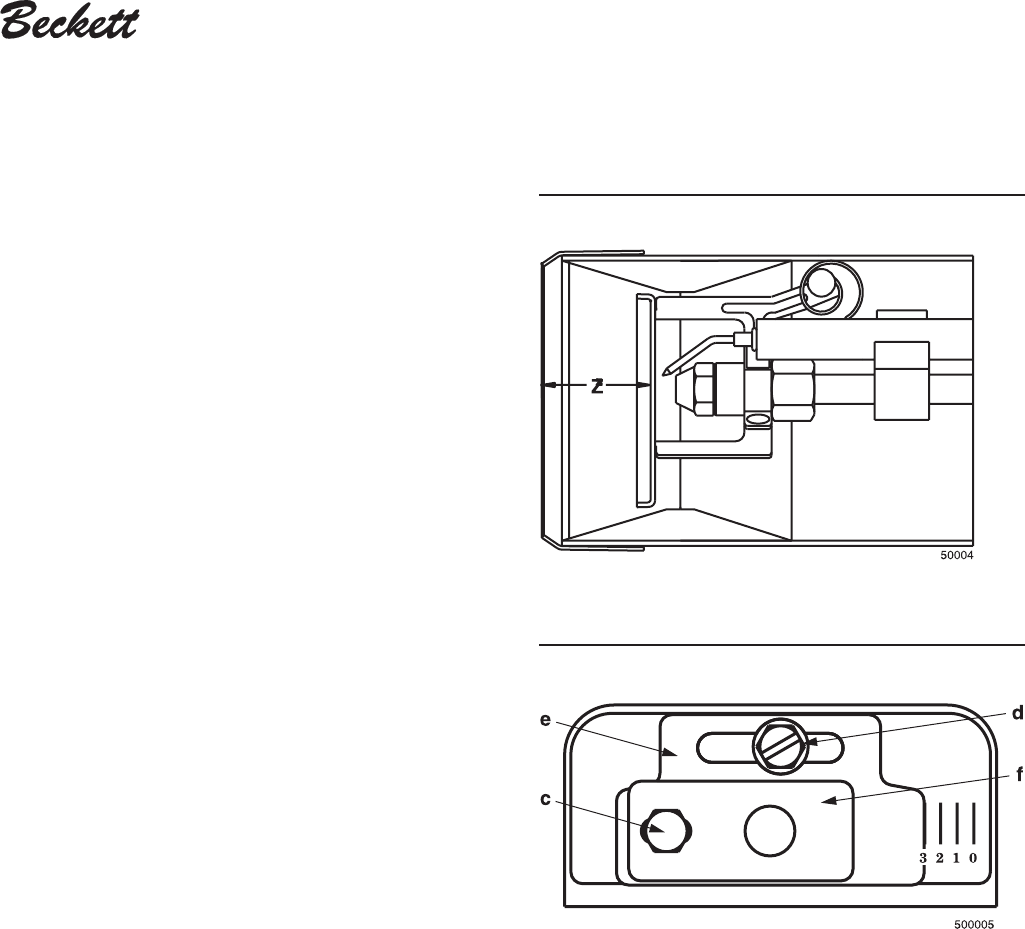

Figure 5 - Nozzle line assembly in burner

Legend

c acorn nut

d fastener

e Indicator adjusting plate

f Secondary adjusting plate

Figure 6 - Adjusting plate assembly

❏ Install nozzle line assembly

• Insert the nozzle line assembly into the burner air tube.

• Slide the secondary adjusting plate (

Figure 6, item f) com-

pletely to the left on the indicator adjusting plate (item

e).

Finger-tighten acorn nut

c to secure the two plates together.

Slide both plates completely to the right (Indicator plate

will read

0). Tighten fastener d.

• Install the spline nut on the end of the nozzle line, leaving

the nut loosely placed so the plates can be moved.

❏ Set dimension Z

• Loosen fastener c in Figure 6. Slide the nozzle line and

plate assembly until dimension Z in Figure 5 is:

CF500 — 1

9

/

16

" ±

1

/

16

"

CF800 — 1

3

/

4

" ±

1

/

16

"

When dimension Z (from end of air tube to flat area of front

face of head) is correctly set, tighten acorn nut c.

• Attach the oil line from the oil valve to the nozzle line end.

Tighten securely.

• Before proceeding, check dimension Z once again. Loosen

acorn nut c if necessary to reposition the nozzle line. Once

dimension Z is set, do not loosen acorn nut again. For the

setting of fastener d, refer to page 12.

❏ Insert burner

• Position the burner in the front of the appliance and loosely

tighten the nuts on the mounting studs. The burner should

be pitched downward 2° as shown in Figure 3.