12

Form 6104 BCF5-R0301

Instruction Manual – Model CF500/CF800 Oil Burner

❏ Z dimension

• Should be set per these instructions (see page 7). The acorn

nut (Figure 6, item c, page 7) should never be loosened

once the Z dimension is initially set.

❏ Initial head position

• The indicator plate assembly markings correspond to head

position settings.

• Loosen the fastener (Figure 6, item d, page 7) and slide

the indicator plate until the number on the plate corre-

sponds to the initial head setting given in Table 4 for the

desired firing rate.

• When the head position has been set, tighten the fastener

and spline nut.

❏ Initial air settings

• Loosen the air band and shutter, and adjust to the settings

for the applicable firing rate shown in Table 5.

• These initial settings should be adequate for starting the

burner. Once the burner is in operation, the air settings will

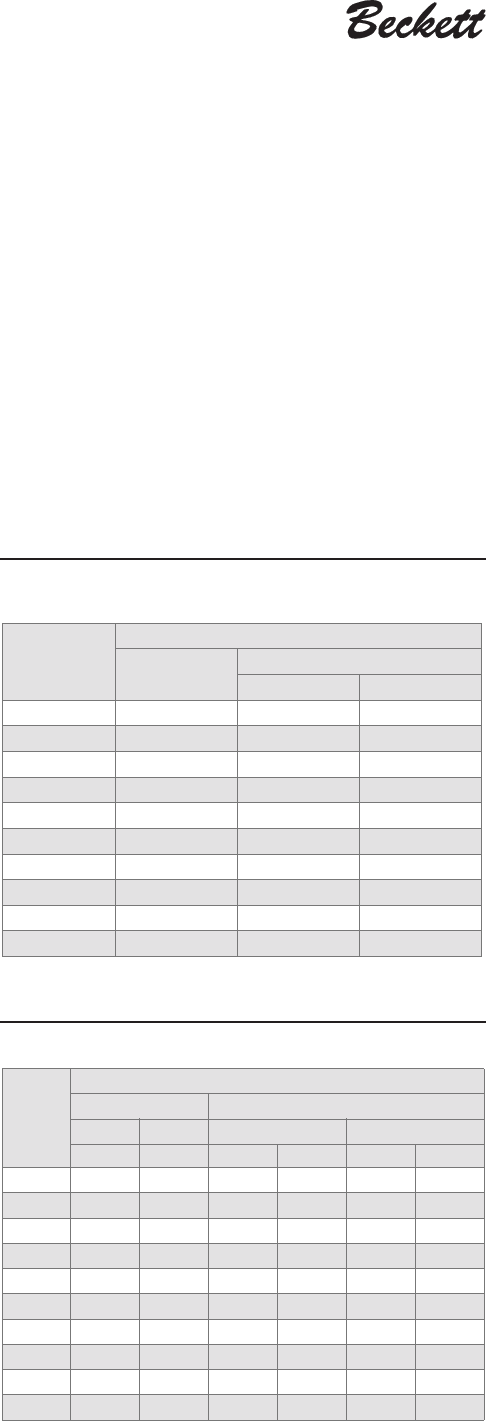

Table 4 – Initial indicator adjustment plate settings

(head position)

Prepare the burner for start-up

Start-up checklist – Verify the following

before attempting to start burner.

❏ Combustion air supply and venting have been inspected

and verified to be free of obstructions and installed in

accordance with all applicable codes.

❏ Oil nozzle has been selected correctly and securely installed

in the nozzle adapter.

❏ Fuel unit by-pass plug

has not been installed for one-pipe

oil system.

By-pass plug has been installed for two-pipe oil system.

❏ Fuel connection to nozzle line assembly is secure.

❏ Dimension Z has been set per this instruction manual.

❏ Fuel supply line is correctly installed, the oil tank is

sufficiently filled, and shut-off valves are open.

❏ Burner is securely mounted in appliance, with pressure

firing plate and gasket installed for pressurized chamber

application.

❏ Appliance has been filled with water (boilers) and controls

have been operationally checked.

❏ Burner has been installed in accordance with appliance

manufacturer’s instructions (when available).

❏ Also refer to appliance manufacturer’s instructions (when

available) for start-up procedures.

Table 5 – Initial air settings

Rate

GPH

Approximate air settings

CF500 CF800

Tube A Tube B

Shutter Band Shutter Band Shutter Band

1.75 1 0 -- -- -- --

2.25 2 0 -- -- -- --

3.00 10 1 1 0 -- --

3.50 10 2 3 0 -- --

4.00 10 3 4 0 -- --

5.00 10 5 9 0 8 2

5.50 10 10 9 5 9 4

6.00 -- -- 10 3 10 3

7.00 -- -- 10 8 10 5

8.00 -- -- -- -- 10 10

be adjusted for best performance as discussed later in this

manual.

• Follow the procedures given later in this manual for fine-

tuning the air settings.

❏ Set appliance limit controls

• Set the appliance limit controls in accordance with the

appliance manufacturer's recommendations.

❏ Prepare the fuel unit for air venting

• To vent air from one-pipe oil systems, attach a clear hose to

the vent plug on the fuel unit. Provide a container to catch

the oil. Loosen the vent plug.

• Vent the air as described under Start the burner, page 13,

when using the R7184 control.

Rate

GPH

Approximate head settings

CF500 CF800

Tube A Tube B

1.75 0----

2.25 0

3.00 40--

3.50 5 1 --

4.00 5 2 --

5.00 6 4 3

5.50 6 4 4

6.00 -- 4 4

7.00 -- 6 5

8.00 -- -- 6