Manual 2100-516H

Page 15 of 19

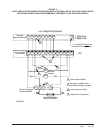

FIGURE 11

HEAT PUMP WITH CS2000A2

JUMPER IS FACTORY INSTALLED.

LIGHTING CONTROL CIRCUIT

IS OPTIONAL AND FIELD

SUPPLIED. LIGHTING CONTROL

RELAY REQUIRES NORMALLY

CLOSED CONTACTS AND MUST

BE SIZED ACCORDING TO

CONTROLLED LOAD.

2

1

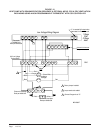

CONTROLLER BARD P/N 8403-060

90

SEARCH-TIME

84

LIGHTS

TEMPERATURE SWITCHES

LEARN

FUNCTION SWITCHES

DEMAND 1

DEMAND 2

AUX

STAGE

N/C

RATE

MODE

PRE P

RECOMMENDED SWITCH SETTINGS SHOWN BELOW

48

54

58

62

68

65

81

78

1

TEMPERATURE/HUMIDITY

Figure 11

DO NOT CONNECT "L" UNTIL AFTER

TERMINALS

G

O/B

OPTIONAL

OR

C

E

R

E

O/B

C

G

R

Y

Y1 B

CRV

6

UNIT 24V

O

G

Y

W1

C

DEHUMIDSTAT

THERMOSTAT TH5220D1151

WERV

L

W1/E

ON PAGE 3

L

1

HUMIDITY CONTROLLER

L

SEARCH TIME DETAIL

TO CS2000 = YES

FACTORY JUMPER - SEE

AND ORANGE WIRES

WH/SH HEAT PUMP CONNECTION DIAGRAM

RC

CONTACTS

OPEN

NORMALLY

(OPTIONAL)

DETECTOR

MOTION

LIGHTING CONTROL

CONTROLLER

PACKAGE (OPTIONAL)

SETTINGS).

INSTALLED IN HEAT PUMP

BARD P/N 8403-058

HP WITH CS2000

OVERIDE

ENERGY MONITOR

HVAC

NO C NCDOORPRECOND

- +

REMOTE

PWR

- +

C NC

REM

W3

PWR

3

- +

AREA OCCUP.

4

VENT HVAC FAN

R

NOTE: IF FACTORY INSTALLED

5

MAN.

NO C NC

H600A1014

R

H200-10-21-10

CS2000A2

8403-060 CONTROLLER IS CONFIGURED

BARD VENTILATION

BLUE

(SEE STEP 2, FUNCTION SWITCH

CONNECTIONS USED ONLY

HUMIDITY

DISCONNECT AND TAPE RED

8403-038

CIRCUIT THAT MUST BE FACTORY

RELAY NORMALLY

FIELD SUPPLIED

CONTROL

01

8403-047

2

RED

MUST ALSO BE CONNECTED

YELLOW

FOR PRE-PURGE OPERATION

FOR OPTIONAL DEHUMIDIFICATION

Aux

W2

CLOSED CONTACTS

MANUAL SWITCH

LIGHTING

NC C NO C NC

W2

YO/D

Y1

(24 HRS)

IF OPTIONAL VENT PACKAGE IS

INSTALLED, THE "G" WIRE MUST

BE CONNECTED TO ASSURE

CONTINUOUS BLOWER DURING

OCCUPIED PERIODS WHEN VENT

SYSTEM IS "ON". THE "G" WIRE

1

4093-140 L

BK

BR/W