Manual 2100-346

Page 6

A copper-silver alloy with a high silver content should

be used when iron or steel material is involved in the

joint. These alloys require the use of silver solder flux.

Alloys containing phosphorus should not be used with

iron or steel. Phosphorus reacts with the iron forming

iron phosphate which is extremely brittle.

CAUTION

1. Brazing alloys with a melting temperature

below 700° F should not be used. 2. Lead-

tin or tin-antimony solders should not be used

due to their low melting point and necessity for

corrosive fluxes.

To further prevent the formation of copper oxide inside

the tubing, dry nitrogen may be purged through the

refrigerant system during brazing.

WARNING

Never purge or pressurize a system with

oxygen. An explosion and fire will result.

10. After brazing, quench with wet rag to cool the joint and

remove any flux residue.

11. Leak test all connections using an electronic leak

detector or a halide torch.

12. Evacuate suction line, liquid line and indoor unit

through outdoor unit base valves.

13. Open both the suction and liquid base valves to the

fully open position. Refer to section later in installation

instructions for details on setting proper system charge.

FIELD FABRICATED TUBING CONNECTIONS:

QUICK CONNECT INDOOR UNIT and SWEAT

OUTDOOR UNIT USING CTO KIT

Use only refrigeration grade (dehydrated and sealed) copper

tubing. Care must be taken to insure that the tubing is kept

clean and dry before and during installation. Do not remove

the plugs from the tubing ends, coil connections or base

valves until the connection is ready to be brazed.

The suction line must be insulated with a minimum of 3/8”

Armaflex or equivalent before cutting and making

connections.

1. Being careful not to kink, route both the suction line and

liquid line between the indoor unit and outdoor unit. Use

a tubing bender to make any necessary bends in tubing.

When necessary to bend the insulated tube suction line,

cut the insulation around its circumference at a distance

far enough beyond the point of the bend so as to clear the

tubing bender. Slip the insulation back together and

vapor seal the joint with tape. Coil any excess tubing in

a horizontal place with the slope of the tubing toward the

condensing unit. See Figure 3.

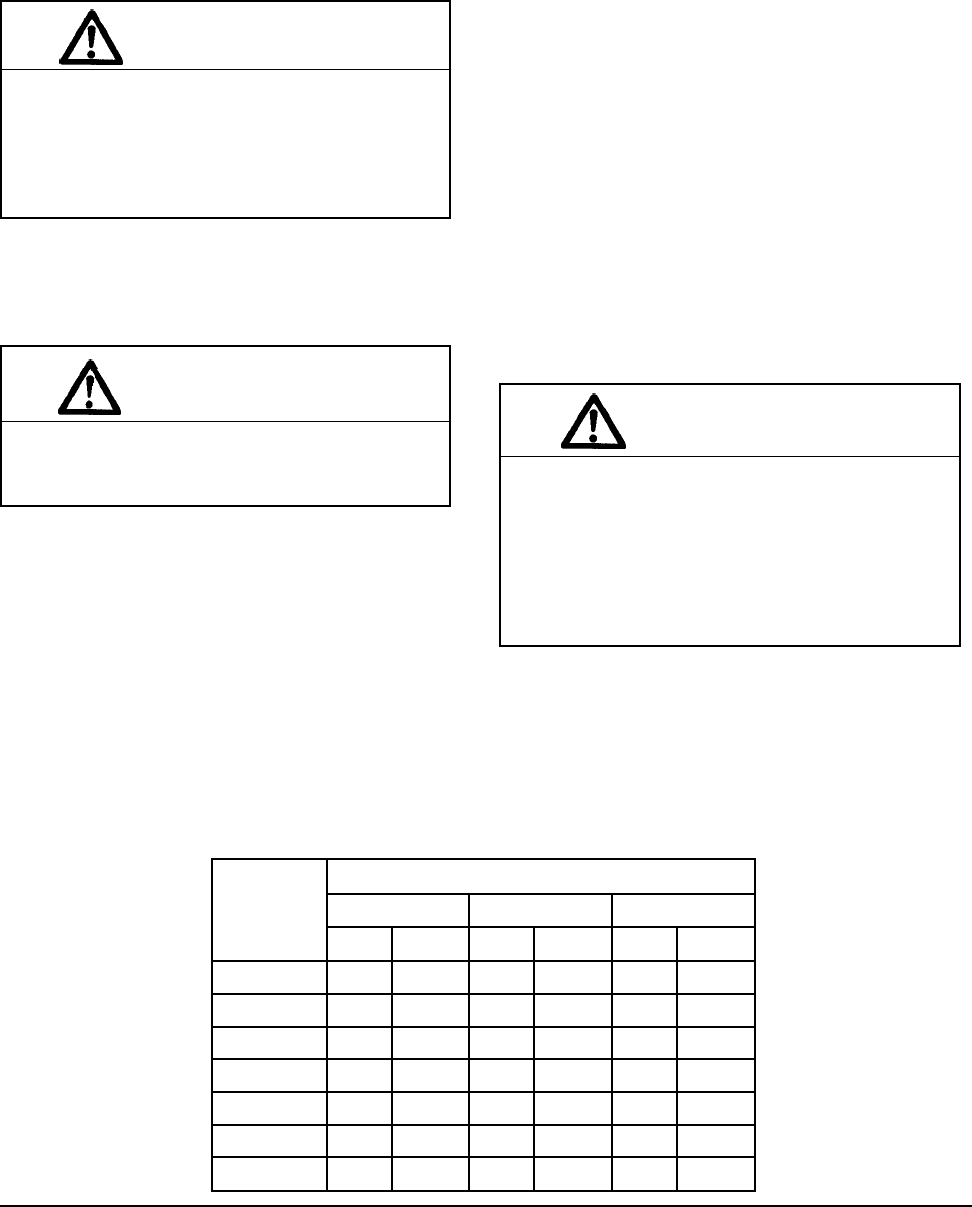

TABLE 4

TUBING CHART

cisaB

gnisnednoC

ledoMtinU

).tF(htgneLeniLtnaregirfeR

02-006-12001-16

diuqiLnoitcuSdiuqiLnoitcuSdiuqiLnoitcuS

181CAH"4/1"8/5"4/1"8/5"8/3"4/3

142CAH"8/3"8/5"8/3"4/3"8/3"4/3

103CAH"8/3"8/5"8/3"4/3"8/3"4/3

163CAH"8/3"8/5"8/3"4/32/1"8/7

124CAH"8/3"4/3"8/3"8/72/1"8/7

184CAH"8/3"8/7"8/3"8/72/1"8/1-1

106CAH"8/3"8/7"8/3"8/72/1"8/1-1

CAUTION

1. Be careful not to tear the insulation when

pushing it through hole in masonry or frame

walls. 2. When sealing the tube opening in

house wall, use a soft material to prevent tube

damage and vibration transmission. 3. Avoid

excessive bending in any one place to avoid

kinking.