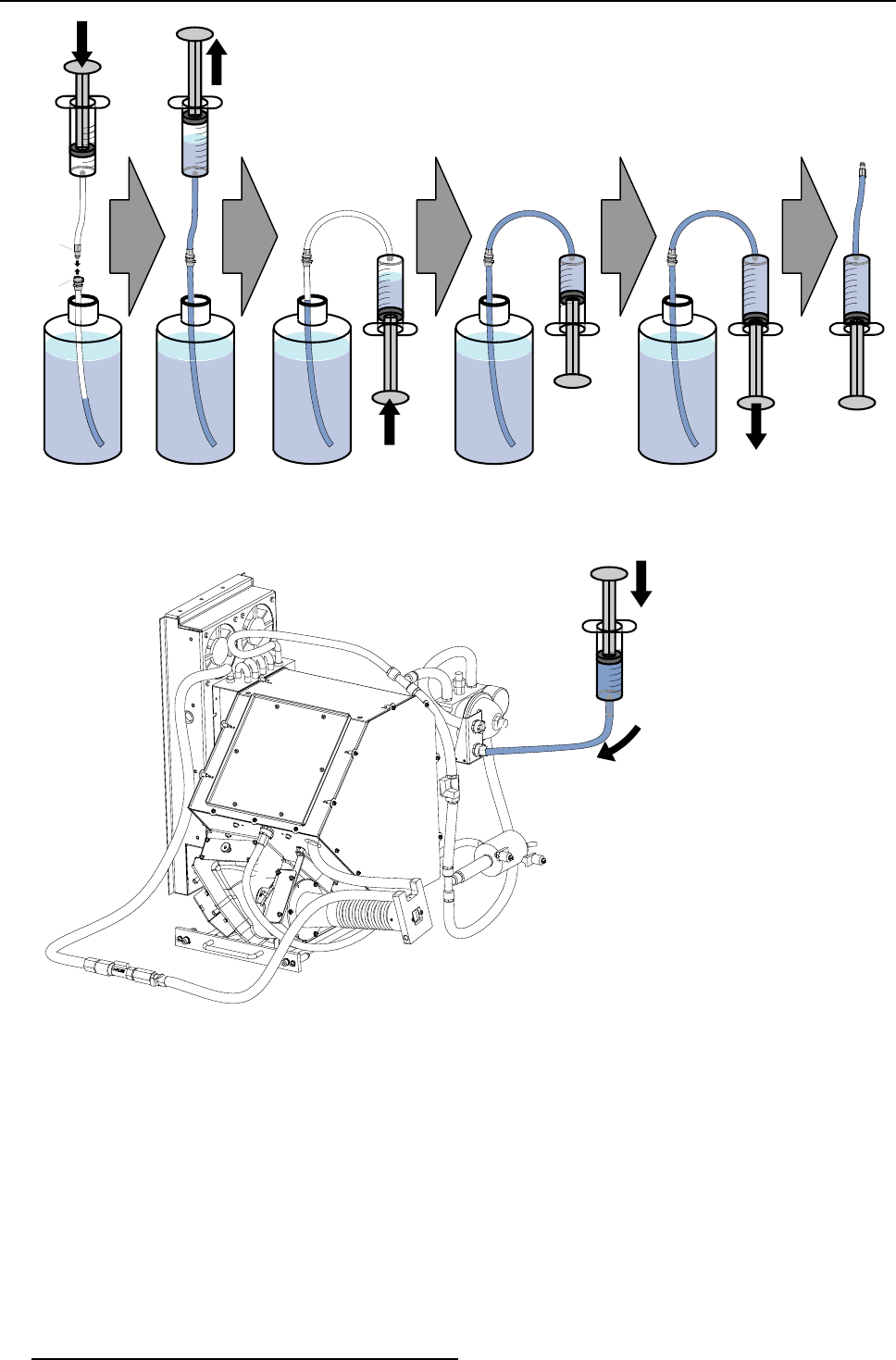

2. Servicing the liquid cooling circuit

abc d e f

M

F

Image 2-13

2. Couple the syringe to the inlet of the cooling circuit and press the cooling liquid inside the circuit until the manometer indicates 1

bar pressure. Ensure that no air bubbles are injected into the circuit.

Caution: Maximum 1 bar of pressureis allowed on the liquid cooling circuit. More pressure than 1bar maydamage the circuit.

IN

Image 2-14

Pressurize cooling circu it

3. Check if the cooling c ircuit was correctly calibrated. Proceed as follows:

a) Taking note of the liquid level in the syringe, while pressurizing the cooling circuit up to 1 bar (see previous step).

b) Release the plunger. As a result the pressure of the cooling circuit will drop from 1 to 0 bar and cooling liquid is automatically

expelled from the circuit into the syringe.

c) Check if the amount of expelled liquid is between 50 and 70 ml. If not, start the procedure "Calibrating the liquid cooling

circuit", page 17.

d) Push the p lunger of the syringe to reinject t he expelled liquid b ack into the circuit. The pressure would hence return to 1 bar.

4. Disconnect the syringe from the cooling circuit. Make s ure that the pressure r emains 1 bar.

5. Check that the vane is open.

16

R59770032 COOLING LIQUID REFURBISHMENT 07/12/2006