SECTION 2

HGM300 / RDM800 Refrigerant Gas Leak Monitor

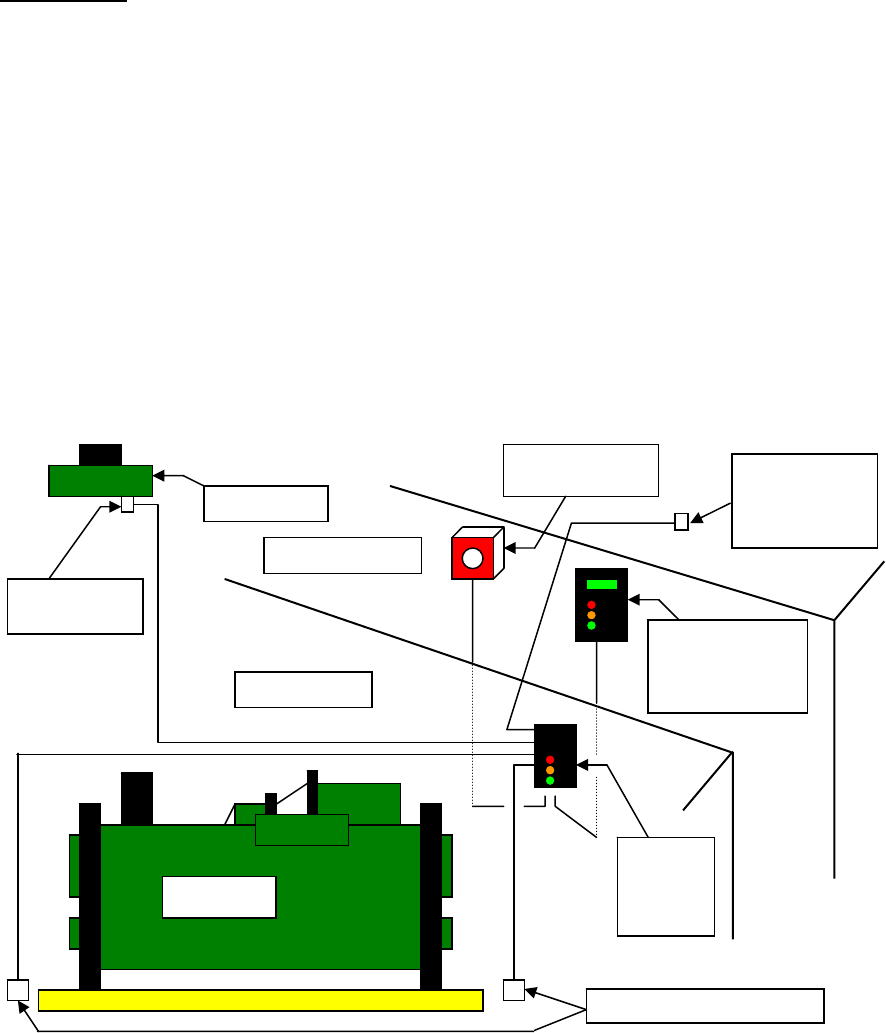

Mechanical Room Placement

The HGM300 should be centrally located in the mechanical room and be readily accessible for easy

visual monitoring and servicing. Air sample tubing may be run in lengths up to 500 feet.

The fresh air purge line should draw from an area that does not contain any refrigerant gas and

cannot exceed 300 feet in length. The exhaust line should run to an outside location if possible.

The length of the exhaust line cannot exceed 300 feet.

Ideally, two to three pick up points spaced around each chiller will provide sufficient coverage. It may be

necessary to perform a “smoke” test of the mechanical room to determine the best locations. The smoke

test would provide the pattern of air currents present in the mechanical room.

Sample Inlet Pickup Points

Chiller

HGM300

Halogen

Gas

Monitor

RDM800

Remote Display

Module outside of

mechanical room

Outside Hallway

Machine Room

Exhaust Fan

Sample Inlet

Pickup Point

Aux. Horn/Strobe

Remote Alarm

Fresh air purge

from area away

from refrigerant

gas

The RDM800 should be mounted outside of the mechanical room, or at least just inside of a door to the

room. This is the “split architecture design” for safety of the operator. The RDM800 can be located up to

4500 feet from the HGM300. The RDM800 is the man-machine interface by which you program the

HGM300, acknowledge alarms, and observe conditions inside of the mechanical room. Note that there

are two additional alarm relay contacts in the RDM800 that can be programmed to alarm with leak, spill,

evacuate, fault, or monitor on.

3