5

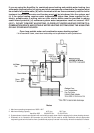

Appliances located in confined spaces:) The confined

space must be provided with two permanent openings,

one commencing within 12 inches of the top and one

commencing within 12 inches of the bottom of the

enclosure. Each opening must have a minimum free area

of one square inch per:

- 1000 Btu/hr if all air is taken from inside the building.

- 2000 Btu/hr if all air is taken from the outside by horizontal

ducts.

- 4000 Btu/hr if all air is taken from the outside by direct

openings or vertical ducts.

Louvers, grills and screens have a blocking effect. If the

effective free area is not known, increase the sizes of your

openings by 75% if your louvers are wood and by 30% if

your louvers are metal. Refer to the National Fuel Gas

Code for complete information. In buildings of tight

construction all air should be taken from outside. That

would be 2000 cubic feet for the Aquastar 38B alone.

CLEARANCES

The Aquastar 38 B is design certified for installation on a

combustible wall and for installation in an alcove or closet

with the minimum clearances to combustible and non -

combustible construction listed below

A. Top 12 inches ( 305 mm)

B. Front 4 inches (102mm)

C. Back 0 inches

D. Sides 4 inch (102mm)

E. Bottom 12 inches (306 mm)

Clearance from vent is dependent upon the clearance

rating of the venting material used. For example: type B-1

vent is approved for 1 inch clearance, B-2 vent for 2 inch,

etc.

Note: Minimum clearance to combustible materials should

not be less than 6" for single wall flue pipe. Note that this

clearance can be reduced if combustible material are

protected as per table VI of the National fuel Gas Code or

if Type B gas vent is used.

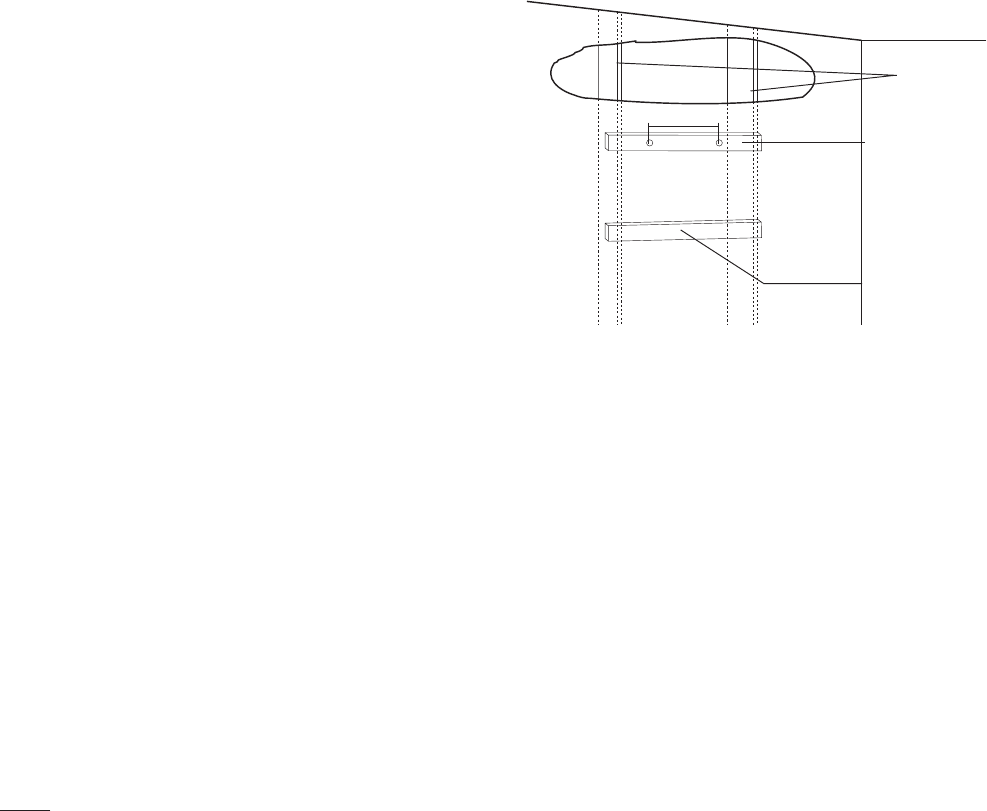

MOUNTING INSTALLATION

The Aquastar 38 B is design certified for mounting on a

wall.

Do not install this appliance on a carpeted wall or over

floor covering which is combustible, such as carpet. The

heater must be mounted on a wall using appropriate

anchoring materials. If wall is a stud wall sheathed with

plasterboard, it is recommended that support board(s),

either 1x4’s or 1/2" (minimum) plywood first be

attached across a pair of studs and then the heater

should be attached to the support boards. See Fig 1.

Expansion and contraction of piping due to changing water

temperature in the pipes imparts movement to the heater

which, if mounted directly to a brittle, friable board, such

as plasterboard, can cause failure of mounting.

Before installing the unit, be certain you have the correct

heater for your type of Gas – Propane or Natural Gas.

Fig. 1 - Mounting the Heater

Identification labels are found on the shipping box, and on

the rating plate which is located on the right side panel of

the cover. Also, each burner orifice is stamped with a num-

ber (79 for LPG and 120 for Natural Gas).

VENTING

Vent pipe connection. WARNING: Do not reduce the

vent pipe size.

This appliance must be vented to the outside following all

local ordinances and specifications for installing a gas

appliance vent or chimney. The venting system must be

designed and constructed so as to develop a positive flow

adequate to remove flue gasses to the outdoors. Minimum

vent size must be 4". Minimum height must be 6 feet,

provided there are no elbows. Termination of vent

must be 2 feet above any obstruction within a 10 foot

radius. Consult your gas utility or National Fuel Gas

Code if vent will have elbows or share venting with

another appliance. The vent connector should have

as much vertical rise as possible (minimum 12”) before

any horizontal run. The appliance must be located as

close as practicable to a chimney or vent. The vent pipe

sections must be secured to each other with sheet metal

screws. Keep in mind the minimum clearance from the

top of your heater. Remember also that single wall vent

pipe connectors require a 6 inch clearance from

combustibles. National Fuel Gas Code specifies double

wall — Type “B” — vent pipe be used in cold climates and

for gas vents running through attics. We consider double

wall vent pipe preferable in all circumstances. Any vent

section greater than 45 degrees from vertical is considered

horizontal. Horizontal sections of vent connectors must

slope upwards at least 1/4 inch for every foot of its

horizontal length. Keep the horizontal section short and

avoid too many elbows.

WALL STUDS

1” X 4”

SPACE BOARD

SUPPORT BOARD

5 ½”