VENTILATION OR AIR CYCLING (CONTINUED)

DETERMINE FRESH AIR DELIVERY RATE

1. Measure the negative static pressure of the return system at the location where the outdoor air duct enters the return duct.

2. See Table 4 for estimated inlet airflow in CFM, based on duct type, length, and available negative pressure. Use an airflow measuring device

for a more accurate airflow delivery rate.

3. Record the Delivered CFM. __________

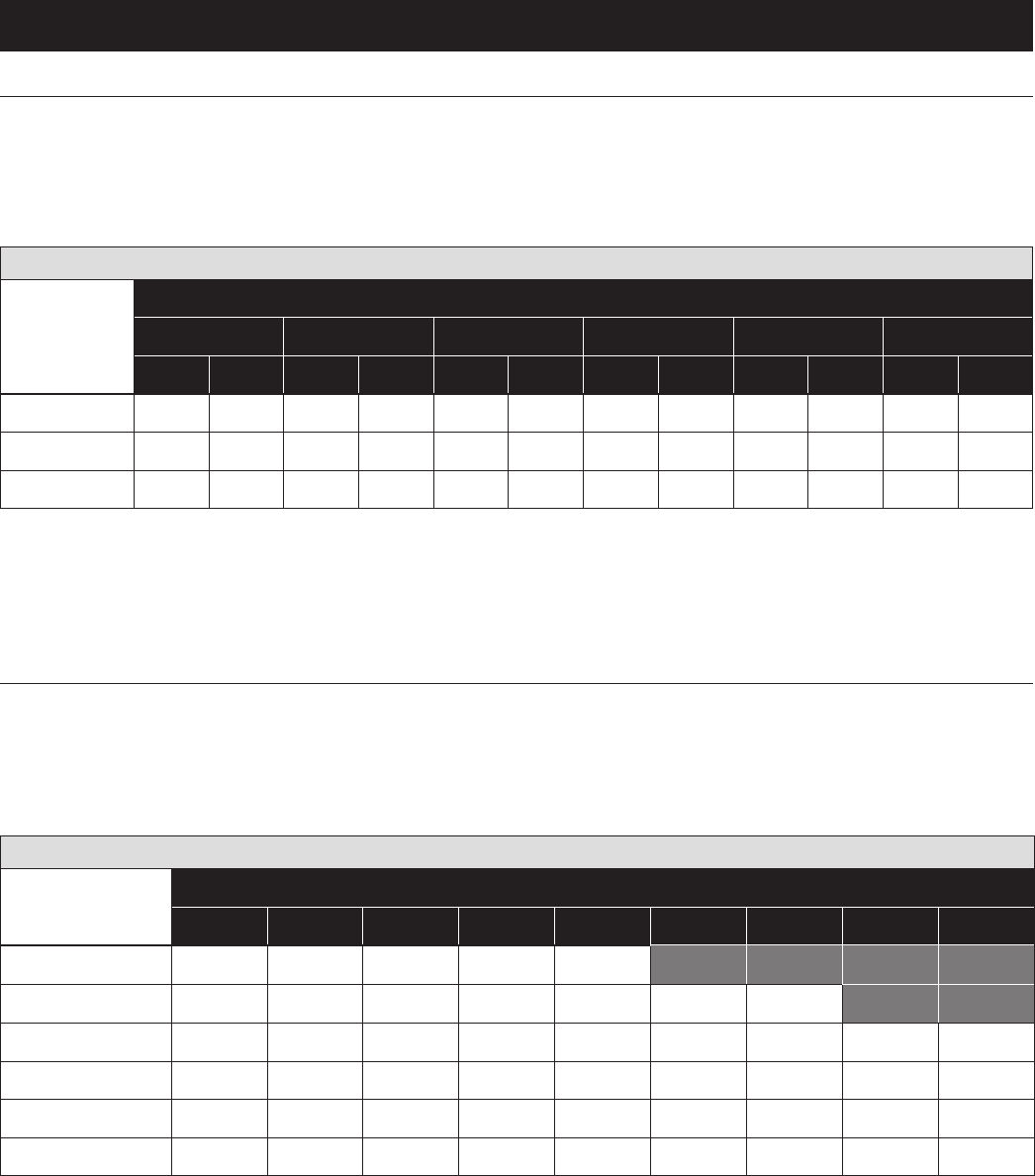

TABLE 4 – CFM Delivered

Duct Length

Negative Static Pressure (“w.c.) as Measured for Return Duct or Plenum

0.05 0.1 0.15 0.2 0.25 0.3

Flex Pipe Flex Pipe Flex Pipe Flex Pipe Flex Pipe Flex Pipe

10 ft.

60 65 85 90 105 110 120 125 135 140 150 160

20 ft.

55 60 80 85 100 105 115 120 130 135 140 150

30 ft.

50 55 75 80 95 100 110 115 125 130 130 140

Note: For the table above, 6” flex duct is laid loose with two, wide 90° bends and a fully opened damper. Rigid pipe values are based on 6” duct,

two 90° elbows, and a fully open damper. In both cases, the air intake is through a metal vent hood with inlet screen. Airflow may need to be

adjusted up or down for variations in duct work.

DETERMINE CYCLE TIME

1. Use the Required CFM and Delivered CFM from the above steps to determine the Cycle Time from Table 5.

2. The values are listed for a 1 hour Cycle Period. For a 2 hour Cycle Period, set the Cycle Time to twice the values listed in Table 5.

3. The values highlighted in gray cannot be set due to the maximum 60 minute Cycle Time. A second ventilation device (i.e., bigger duct or

second duct) will be required to meet ventilation needs.

TABLE 5 – Cycle Time Setting (minutes) for Airflow Delivered vs. Airflow Required for 1 hour Cycle

CFM Delivered

CFM Required

20 30 40 50 60 70 80 90 100

60

20 30 40 50 60

70 80 90 100

80

15 25 30 40 45 55 60

70 75

100

15 20 25 30 35 40 50 55 60

120

10 15 20 25 30 35 40 45 50

140

10 15 15 20 25 30 35 40 45

160

10 10 15 20 25 25 30 35 40

13