9

3. Make sure that plastic tubing is still attached to the pressure

switch and fan housing. Also make sure that wiring connector

from motor to control box is securely attached.

4. Do not plug in power cord until vent system is completely

installed. The Power Vent operates on 120 Vac, therefore a

grounded outlet must be within reach of the 6 foot flexible

power cord supplied with the vent (see fig.1). The power cord

supplied may be used on unit only where local codes permit.

If local codes do not permit use of flexible power supply cord:

A. Remove screws that hold cover plate on control box and

remove plate.

B. Cut flexible power cord on inside of control box, as close

to inside wall as possible.

C. If flexible cord and strain relief are removed, then opening

in box must be covered by a plastic cap on the front side

of the control box.

D. Remove plastic cap on the right side of control box and

install suitable conduit fitting in enclosure.

E. Splice field wiring into existing wiring using code

authorized method (wire nuts, etc).

F. Be certain that neutral and line connections are not

reversed when making these connections.

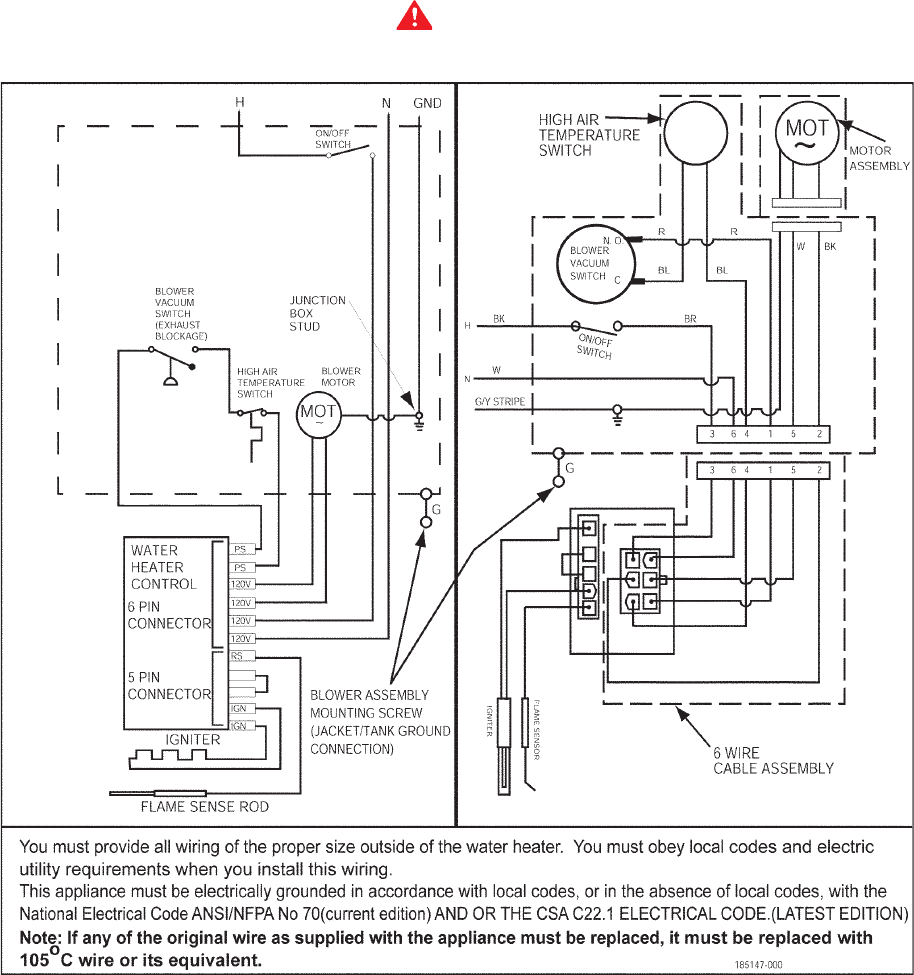

G. Ground heater properly. This water heater must be

grounded in accordance with the National Electric Code

ANSI/NFPA70 and/or local codes. These must be followed

in all cases.

The water heater must be connected to a grounded metal,

permanent wiring system; or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment grounding terminal or lead

on the water heater, see Figure 7.

H. Replace cover plate and secure with two screws.

5. The blower discharge boot is made to accept only straight

sections of 3" pipe. To start off with an elbow, a short section

of the furnished pipe, a minimum of 2 inches, must be cut

and glued into the end of the elbow that will mount on the

discharge boot (see fig. 6).

POWER VENT WIRING SCHEMATIC - FIGURE 7

CAUTION

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS. WIRING ERRORS CAN

CAUSE IMPROPER AND DANGEROUS OPERATION. VERIFY PROPER OPERATION AFTER SERVICING.