10

POWER VENT (OPTIONAL)

The length of vent used in horizontally vented installations can be

extended beyond the lengths shown in Tables 11 and 13 by

implementing the kits listed below:

TABLE 9: POWER VENT KITS.

CONNECTING BOILER TO A COMMON VENT

Do not connect the boiler to a common vent or chimney with solid

fuel burning equipment. This practice is prohibited by most local

building codes as is the practice of venting gas fired equipment to

the duct work of ventilation systems.

Where a separate vent connection is not available and the vent

pipe from the boiler must be connected to a common vent with an

oil burning furnace, the vent pipe should enter the common vent or

chimney at a point ABOVE the flue pipe from the oil furnace.

UL/ULC listed double wall type B-1 gas vents, through 16" diameter,

can be installed in heated and unheated areas and can pass

through floors, ceilings, partitions, walls and roofs, provided the

required clearance is observed.

At the time of removal of an existing boiler, the following steps shall

be followed with each appliance remaining connected to the

common venting system. Perform these steps while the other

appliances remaining connected to the common venting system

are not in operation.

1. Seal any unused opening in the common venting system.

2. Visually inspect the venting system for proper size and horizontal

pitch and determine there is no blockage or restriction, leakage,

corrosion or other unsafe condition.

3. Insofar as is practical, close all building doors, windows and

all doors between the space in which the appliances remaining

connected to the common venting system are located and other

spaces of the building. Turn on clothes dryers and any

appliance not connected to the common venting system. Turn

on any exhaust fans, such as range hoods and bathroom

exhausts, so they will operate at maximum speed. Do not

operate a summer exhaust fan. Close fireplace dampers.

4. Test fire the appliance(s) being inspected, making sure to follow

the manufacturers lighting and operating instructions.

Appliance(s) operating controls should be adjusted to provide

continuous service.

5. Check vent pressure of the appliance 24 inches (61.0 cm) above

boiler vent collar. Vent pressure should be maintained between

-0.02" W. C. and -0.04" W.C. to assure proper operation. For

appliances with a draft hood, check for spillage with mirror,

smoke or other device five minutes after placing appliance in

operation.

6. After it has been determined that each appliance remaining

connected to the common venting system properly vents when

tested as outlined above, return doors, windows, exhaust fans,

the exhaust vent pipe must be listed for use with category III gas

burning heaters such as "Saf-T-Vent" manufactured by Heat-Fab

Inc. This vent system must be 100% sealed with a condensate

trap located as close to the boiler as possible. When sizing exhaust

piping and intake air piping, 90-degree elbows are equivalent to 10

feet (3.1 m) of straight pipe and 45-degree elbows are equal to 5

feet (1.5 m) of straight pipe.

The intake air piping can be PVC, CPVC, ABS, Galvanized steel or

any suitable intake air piping that can be sealed. See Table 8 for

Direct Vent Kit numbers.

TABLE 8: DIRECT VENT KITS.

HORIZONTAL VENT INSTALLATION

This boiler can be vented through the rear of the cabinet with the

use of the fluebox and vent adaptor. Any of the previous venting

configurations can be installed with rear connections.

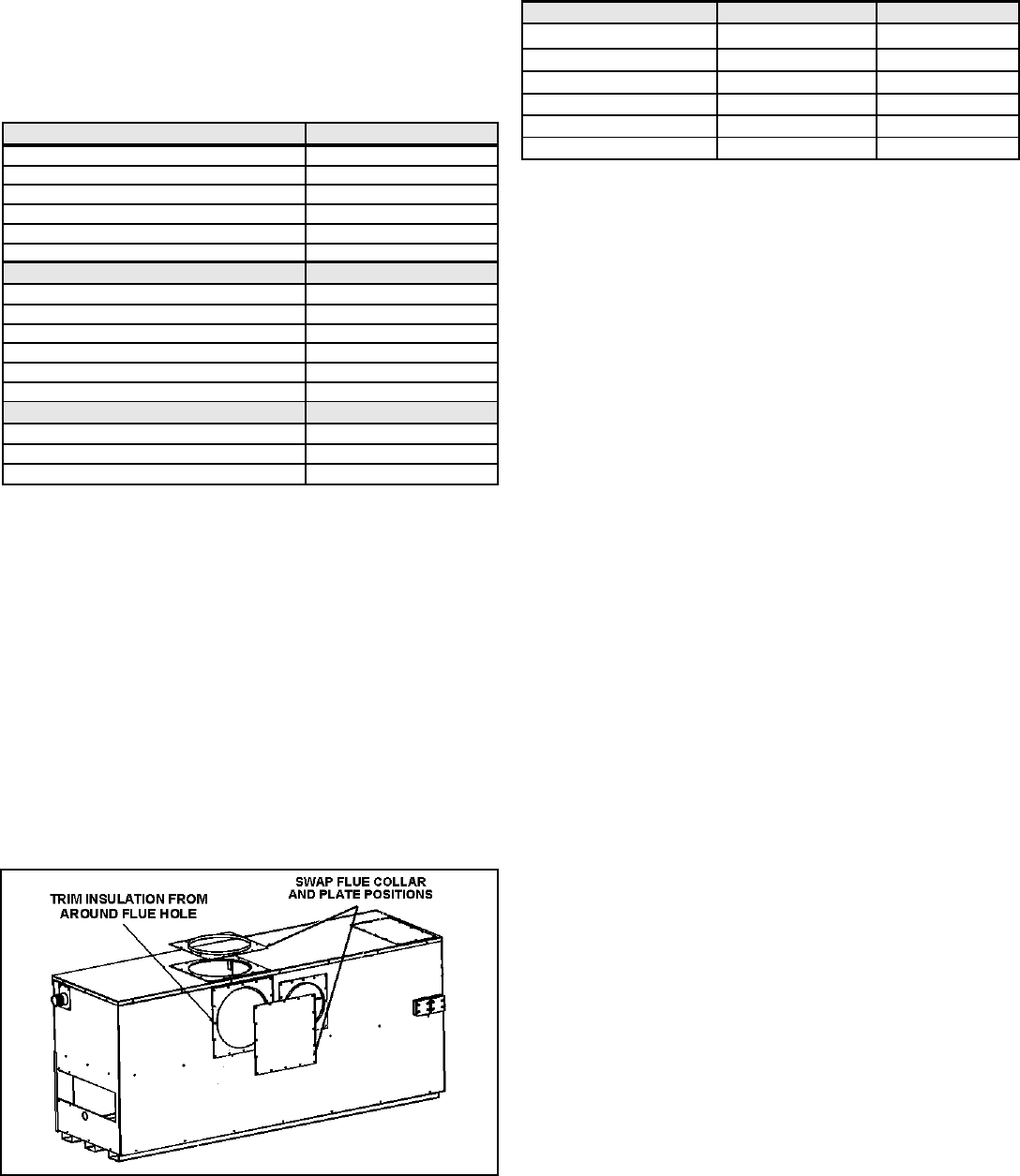

To change the unit to rear exhaust:

1. The vent collar and cover plates must be removed from the top

and rear of the unit.

2. Trim the insulation from around the rear flue hole in the jacket

and the fluebox. Support insulation from inside the fluebox to

facilitate cutting. Use safety precautions such as gloves. Place

the gasket and vent adaptor in the horizontal position. Place

the gasket and flue plate in the vertical position as shown in

Figure 4.

Figure 4. Switching from Vertical to Horizontal Venting.

POWER VENT KIT NO. MODEL MAX. LENGTH

211499 G(B,W) 1000 110' (33.5 m)

211499-1 G(B,W) 1300 100' (30.5 m)

211499-1 G(B,W) 1500 100' (30.5 m)

211499-2 G(B,W) 1850 100' (30.5 m)

211499-3 G(B,W) 2100 100' (30.5 m)

211499-4 G(B,W) 2500 100' (30.5 m)

HORIZONTAL DIRECT VENT KIT NO. MODEL

211090 G(B,W) 1000

211090-1 G(B,W) 1300

211090-1 G(B,W) 1500

211090-4 G(B,W) 1850

211090-2 G(B,W) 2100

211090-3 G(B,W) 2500

VERTICAL DIRECT VENT KIT NO. MODEL

211089 G(B,W) 1000

211089-1 G(B,W) 1300

211089-1 G(B,W) 1500

211089-4 G(B,W) 1850

211089-2 G(B,W) 2100

211089-3 G(B,W) 2500

AIR INTAKE TERMINAL MODEL

191965-2 G(B/W) 1000

211336 G(B/W) 1300,1500,1850

211336-1 G(B/W) 2100, 2500