4

5

BLACK

RED

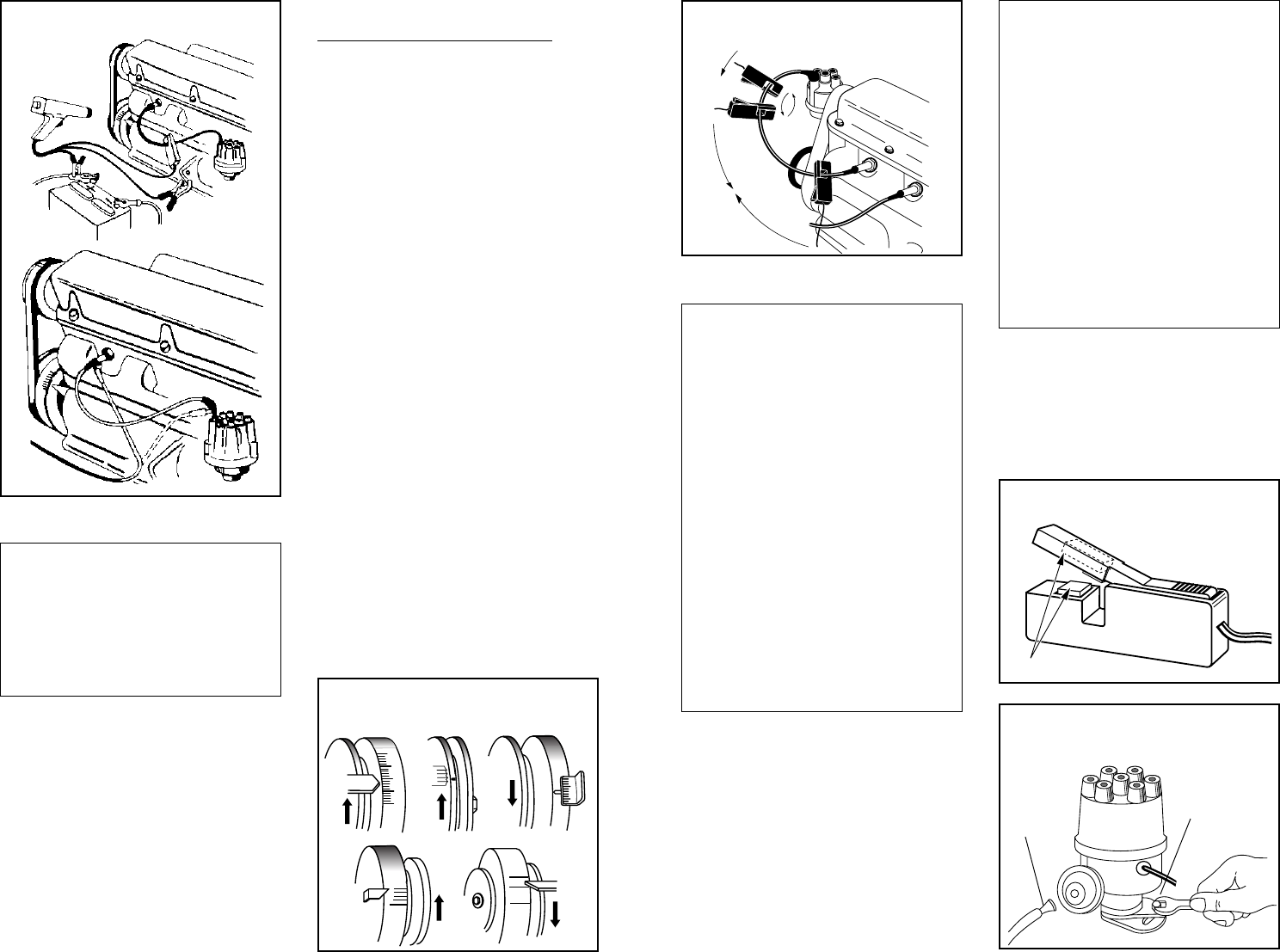

Fig. 1 - Hookup Diagram

Connect the spring adaptor and spark plug

lead between the spark plug (or distributor

cap) and the removed wire as shown in Figure

1. Route the timing light’s spark plug wire away

from the exhaust manifold and surrounding

hot areas to prevent damage.

4. Connect the RED clip to the positive (+)

battery terminal.

5. Connect the BLACK clip to a secure engine

ground such as the alternator bracket or

engine block. For safety reasons, do not

use the negative (-) battery terminal or fuel

system components as a ground connec-

tion point.

NOTE

On some engines, the distributor may be

mounted very close to the carburetor, or

fuel injection throttle body. Since this is an

area in which there may be gasoline vapors

present, it is adviseable on these engines

to remove the number one (1) spark plug

wire only at the spark plug end.

ENGINE TIMING CHECK

(Breaker point equipped engines only)

Check and, if necessary adjust dwell to specifi-

cation before proceeding with timing check.

1. Prepare the engine for timing as indicated

above in ENGINE PREPARATION FOR

TIMING.

2. Clean, and chalk if necessary, both the

rotating and stationary timing marks on the

engine. See Figure 2.

3. Start the engine and allow it to warm to

normal operating temperature (upper ra-

diator hose is hot).

4. Check, and if necessary, adjust RPM to

specified timing speed.

5. When using an advance timing light, make

certain that the advance control is set fully

counterclockwise at “0”.

6. Aim the timing light at the crankshaft damper

(pulley) or transmission bell housing de-

pending on the location of the timing marks

on the engine under test. See Figures 1

and 2.

7. Pull the trigger switch on the timing light

and observe the location of the rotating

mark with respect to the stationary mark. If

timing is within the tolerance as specified

by the manufacturer (typically plus or mi-

nus 2 degrees) no adjustment is necessary

and the procedure is finished. If it is not

within specifications, proceed directly to

the

INITIAL TIMING ADJUSTMENT section

below. If the timing light multiple flashes or

flashes erratically on timing lights equipped

with an inductive pickup, see NOTE below.

Fig. 2 -

Various Timing Light

Configurations

TDC

UDC 1-6

16N

OP 1-6

O

A

3

6

10

0

DC

10

10

8. Shut off the engine. Disconnect the timing

light leads in the reverse order from which

they were connected.

9. Re-connect any disconnected hoses or

electrical connectors which were part of

the engine's preparation for timing. Reset

the engine’s idle speed if necessary.

Timing Adjustments

l. Make certain that the engine has been

prepared for timing as indicated above in

ENGINE PREPARATION FOR TIMING.

LOOSEN

HOLD-DOWN

BOLT

REMOVE

AND PLUG

VACUUM

HOSE IF

REQUIRED

Fig. 3 -

Positioning the Inductive

Pickup for Reliable Readings

NOTE

A defective ignition system may cause the

timing light to multiple flash or flash errati-

cally. Low output spark voltage or a defec-

tive ignition wire may be responsible. You

may be able to steady the flash by sliding

the inductive pickup along the plug wire to

a new location or reversing the inductive

pickup as shown in Figure 3. (This may

also help even with polarity sensitive pick-

ups). Solid copper ignition wires radiate

large amounts of radio frequency noise

through the air which may interfere with the

proper operation of the timing light and

other electronic equipment. Replace solid

copper ignition wire with resistance type

wire if only for the tests described in this

manual. Erratic flashing of the timing light

can also be caused by dirt or grease buildup

on the mating surfaces of the inductive

clamp. To maintain proper operation of the

clamp, clean and dry the inside clamp sur-

faces with a soft cloth when necessary as

shown in Figure 4.

NOTE

The following timing adjustment procedure

can be used on the majority of spark ig-

nited engines in use today. Both General

Motors and Ford Motor Company have

introduced and used special versions of

their common electronic ignition systems

which sense ignition directly from the

engine’s crankshaft via a crankshaft sen-

sor. These systems were introduced in the

late1970’s and were typically used only on

a few of the “high line” luxury passenger

cars. Timing is still checked with a timing

light in the standard manner, however,

timing adjustment is made at the crank-

shaft sensor, not by turning the distributor

as is normally done. See your vehicle serv-

ice manual for exact adjustment proce-

dures on this type system.

2. With the engine off, loosen the distributor

hold down bolt just enough so that the dis-

tributor can be turned freely. Do not loosen

the bolt beyond this point. See Figure 5.

3. Start the engine and allow it to warm to

normal operating temperature (upper ra-

CLEAN AND DRY HERE

Fig. 4 -

Cleaning the Inductive

Pickup

Fig. 5 -

Loosening the

Hold-Down Clamp