YORK INTERNATIONAL

6

FORM 115.20-NOM3 (1006)

INSTALLATION

Many valve packages will not phys-

ically allow all components to fit

over an auxiliary drain pan. It is the

installers responsibility to ensure ad-

equate condensation prevention. The

installer must also ensure that there

is no condensate drippage onto elec-

trical components beneath insulated

components.

6. Avoid rapid quenching of solder joints, as this will

produce joints of inferior quality.

7. The valve package will not support the weight of

the connecting pipes. All pipes, which are connected

to the units, must be completely supported prior to

connection to the unit.

8. Provisions must be made for expansion and con-

traction of piping systems. All horizontal and

vertical risers, including runouts, must be able to

withstand significant movement with temperature

changes. Failure to do so will result in damage and

failure of piping, fittings and valves throughout the

building.

9. Never insulate the heads or motorized portion of

control valves. Damage can occur in the form of

excessive heat build up and interference to the

operation and moving parts will result.

10. All piping made in the field should be installed with

consideration of additional space for any electrical

routing that may be required.

11. Hydronic systems are not designed to hold pres-

surized air and should only be tested with water.

After the system has been proven leak free, all lines and

valve control packages must be insulated as specified

on the building plans.

DRAIN PIPING

Drain line installation must adhere to all code requirements.

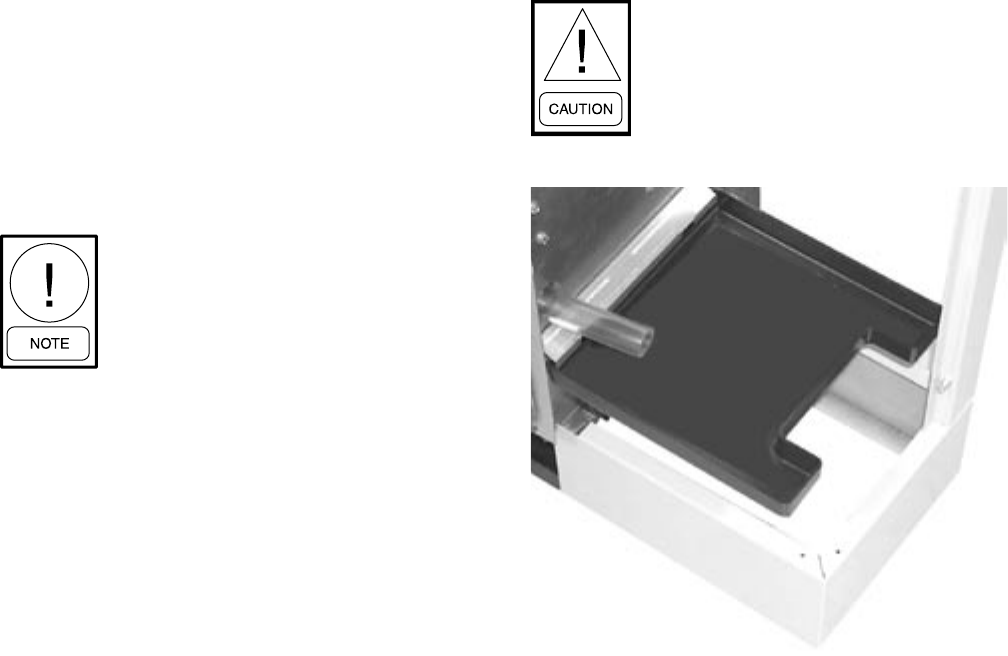

The plastic auxiliary drain pan is to be located under the

coil/valve connections supported by its mounting bracket.

Make sure drain pan is level for proper drainage.

The auxiliary drain pan connection is suitable to receive

a standard 3/4” PVC coupling or elbow. Route the

condensate line such that it will have adequate slope

from the pan to the drain. After condensate line has been

run, make sure plastic drain line from blower plate nipple

is routed to plastic auxiliary drain pan and plastic cap is

installed on other nipple on the blower plate.

Note the 1-1/2” x 4-I/2” indentation in the plastic drain pan

(see Figure 6). This area is provided for the supply and

return runouts if they are brought up from below the pan.

All piping must be well insulated to prevent sweating.

Remove or cover the secondary drain

pan before soldering the supply and

return coil connections as hot solder

or the torch flame may damage the

pan.

00182VIP

FIG. 6 - DRAIN PAN