262675-UIM-A-0806

Unitary Products Group 5

HORIZONTAL SUSPENSION

For suspension of these units in horizontal applications, it is recom-

mended to use angle steel support brackets with threaded rods, sup-

porting the units from the bottom, at the locations shown in Figure 4.

SECTION IV: ELECTRIC HEATER

INSTALLATION

If the air handler requires electric heat, install the electric heat kit

according to the installation instructions included with the kit. After

installing the kit, mark the air handler nameplate to designate the heater

kit that was installed. If no heater is installed, mark the name plate

appropriately to indicate that no heat kit is installed.

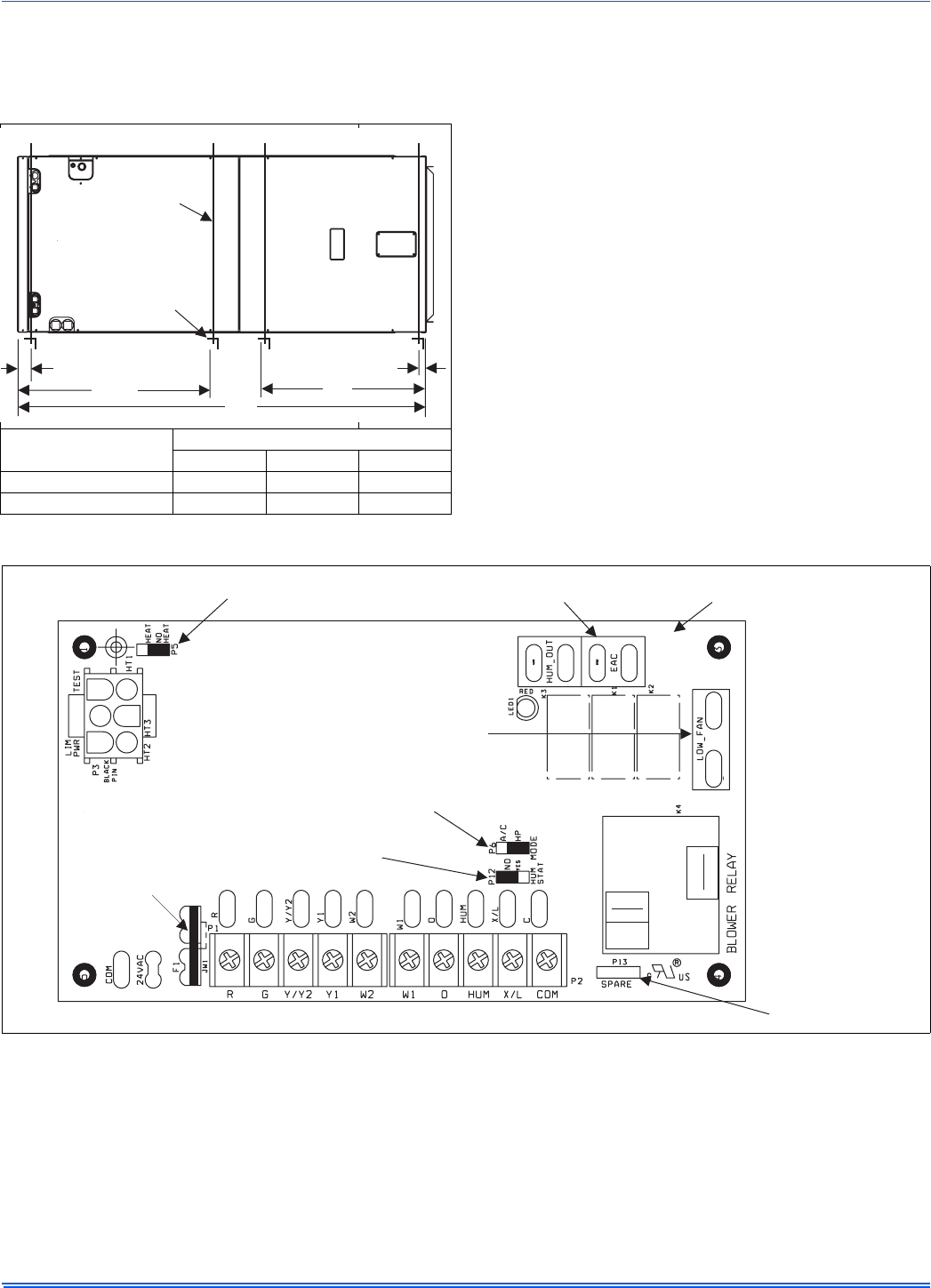

The HEAT ENABLE jumper (See Figure 5) must be moved to the HEAT

position to enable operation of the heater.

Use only 4HK heater kits, as listed on Air Handler name plate and in

these Instructions. Use data from Tables 11 through 18 for information

on required minimum motor speed tap to be used for heating operation,

maximum over-current protection device required and minimum electri-

cal supply wiring size required for listed combination of Air Handler and

Heater Kit.

For Upflow, Downflow and Horizontal right hand applications the kits

can be installed without modification.

Field modification is required for Horizontal left-hand airflow application

only. Follow instructions with heater for modification.

SECTION V: LOW VOLTAGE CONTROL

CONNECTIONS

The 24 volt power supply is provided by an internally wired low voltage

transformer which is standard on all models, However, if the unit is con-

nected to a 208 volt power supply, the low voltage transformer must be

rewired to the 208 volt tap. See the unit wiring label.

Field supplied low voltage wiring can exit the unit on the top right hand

corner or the right hand side panel. Refer to Figure 3.

Remove desired knockout and pierce foil faced insulation to allow wir-

ing to pass through. Use as small of a hole as possible to minimize air

leakage.

Install a 7/8” plastic bushing in the selected hole and keep low voltage

wiring as short as possible inside the control box.

To further minimize air leakage, seal the wiring entry point at the outside

of the unit.

The field wiring is to be connected at the screw terminals of the control

board. Refer to Figures 10 & 11.

Units

(Nominal Tons)

Dimension

WW XX YY

1-1/2 - 3 Ton 16” 48” 22”

3-1/2 - 5 Ton 24” 53” - 58” 22”

FIGURE 4: Typical Horizontal Installation

WW

XX

SUSPENSION SUPPORT LOCATIONS FOR HORIZONTALAPPLICATIONS

2

1-1/2

MIN. 1-1/2” x 1-1/2” Angle

Recommended length

26” minimum

with 2” clearance on

both sides of Air Handler

MIN. 3/8”

THREADED ROD

YY

FIGURE 5: Control Board

HEAT ENABLE

JUMPER

HUM OUT

RELAY OUTPUT

EAC

RELAY OUTPUT

LOW FAN

RELAY OUTPUT

SPARE JUMPER

HUM STAT JUMPER

MODE JUMPER

FUSE