REFRIGERANT MAINS

Many service problems can be avoided by taking adequate pre-

cautions to provide an internally clean and dry system, and by us-

ing procedures and materials that conform with established

standards.

Hard drawn copper tubing should be used where no apprecia

-

ble amount of bending around pipes or other obstructions in

necessary. Use long radius ells wherever possible. If soft cop

-

per is used, care should be taken to avoid sharp bends which

may cause a restriction.

Pack fiber glass insulation and a sealing material such as Per

-

magum around refrigerant lines where they penetrate a wall to

reduce vibration and to retain some flexibility.

Support all refrigerant lines at minimum intervals (8 ft./2.4m)

with suitable hangers, brackets or clamps.

Braze all copper to copper joints witH Sil-Fos 5 or equivalent

brazing material. Do not use soft solder.

Never braze or solder liquid and suction lines together. The

complete suction line should be insulated with no less the

1

2

"

(12mm) ARMAFLEX or equivalent. If the liquid line is installed

in warm space, it must be insulated.

If it is desirable to tape or wire the liquid and suction lines to

-

gether for support purposes, they must be completely insulated

from each other.

INSTALLING REFRIGERANT MAINS

The units are evacuated and dehydrated at the factory and

shipped with a holding charge (1 lb./2.2kg) of Refrigerant-22.

The suction and liquid connections are sealed with copper

disks.

WARNING: Provisions for recovering refrigerant releases

must be available during all phases of installation,

leak testing and charging. Do NOT release refrig-

erant into theatmosphere. ASchradervalve ispro-

vided for refrigerant recovery.

If the unit has already lost its holding charge, it should be leak

tested and the necessary repairs should be made. If the unit

has maintained its holding charge, you can assume that it has

no leaks and proceed with the installation.

Make sure therefrigerant inthe lineshas beenrecovered, then

drill a small holethrough the discs to prevent any internal pres

-

sure from blowing them off and to allow the flow of dry nitrogen

through the connections when unbrazing the closures.

NOTE: To minimize the possibility of system failure due to dirt

and moisture, a filter-drier must be installed in each

liquid line as close to the evaporator as possible.

Filter-driersare notsupplied with the evaporator blow

-

ers. They are supplied with the matching condensing

sections.

The temperature required to make or break a brazed

joint is sufficiently high to cause oxidation of the copper

unless an inert atmosphere is provide.

CAUTION: Dry nitrogen should flow through a brazed joint at

all times when heat is being applied and until the

joint has cooled.

The liquid, suction and drain connections inside the unit

must be piped to the outside. Refer to Unit Dimensions

for locations and dimensions of these connection.

Unitary Products Group 5

550.39-N4YI

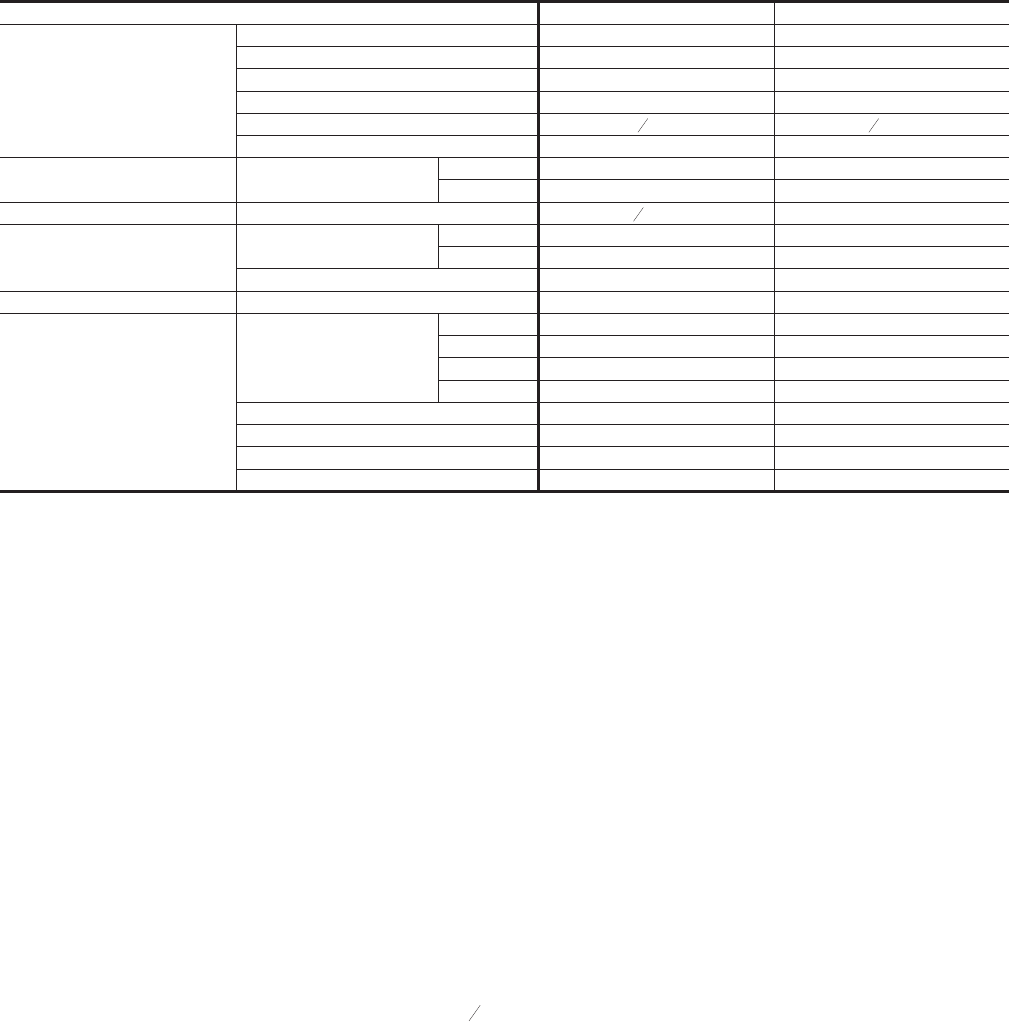

Model KEU090 KEU120

Evaporator Coil

Rows Deep 3 3

Rows High 27 32

Finned Length (in./mm) 46 / 1168 46 / 1168

Fin/Inch 13 13

Tube O.D. (in./mm)

3

8

/ 9.5

3

8

/ 9.5

Face Area (Ft

.2

/m

2

) 8.6 / 0.80 10.2 / 0.95

Centrifugal Blower Wheel Dia. x Width

inches 15 x15 15 x 15

mm 381 x 381 381 x 381

Blower Motor* Nominal Rating (HP/kW) 1

1

2

/ 1.12 2 / 1.5

Filters

(4 Req'd)

Size

inches 16 x 25 x 1 16 x 25 x 1

mm 406 x 635 x 25 406 x 635 x 25

Face Area (Ft.

2

/m

2

) 11.1 / 1.03 11.1 / 1.03

Weight (Lbs,/kg) Operating 325 / 147 330 / 150

Accessory Weights(Lbs/kg)

Electric Heaters

10 kW 63 / 28.6 63 / 28.6

16kW 66 / 30 66 / 30

26kW 71/32 71/32

36 kW 74 / 33.6 74 / 33.6

Supply Air Plenum 102 / 46 102 / 46

Base 60 / 27 60 / 27

Return Air Grille 15 / 6.8 15 / 6.8

Hot Water Coil 105 / 48 117 / 53

*Allofthese1450RPMmotorshaveasolidbase,a56frame,inherentprotectionandpermanentlylubricatedballbearings.RefertoTable7foradditionalmotoranddrive

data.

NOTE: Refer to the appropriate condensing unit installation instruction for charging data.

Table 2 - PHYSICAL DATA