107272-UIM-B-1105

30 Unitary Products Group

The building structure should not be weak end by installation for the gas

piping. The piping should not be supported by the other piping, but

should be firmly supported with pipe hooks, straps, bands, or hanger.

Butt or lap welded pipe should not be bent.

The gas piping should be so installed so as to prevent an accumulation

of condensation and it must be protected against freezing. A horizontal

pipe should be pitched so that it grades toward the meter and is free

from sags. The pipe can not be run through or in an air duct or clothes

chute.

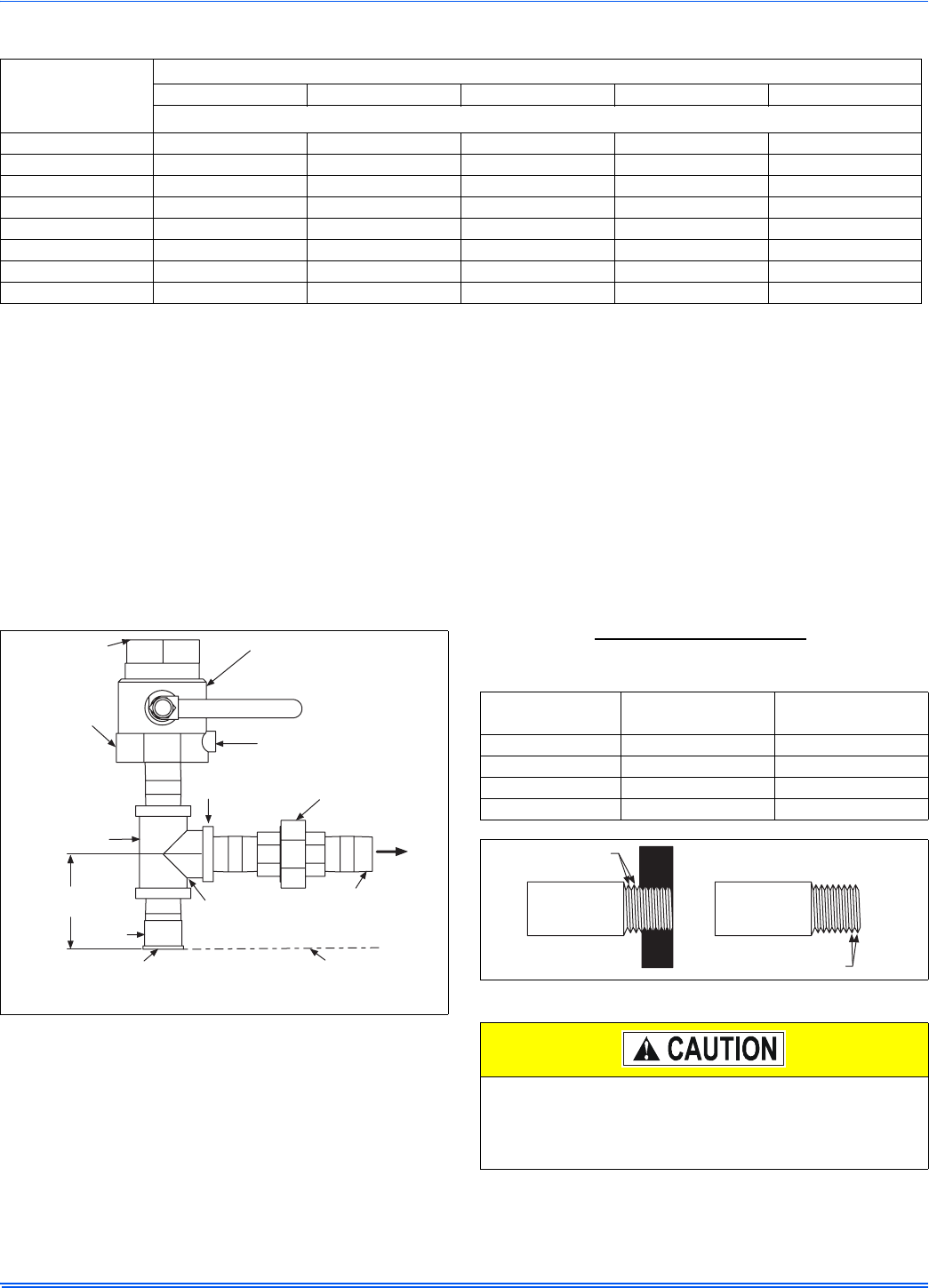

The appliance and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing of the

system at test pressure in excess of 1/2 (3447 PaG) psig.

The appliance must be isolated from the gas supply piping system by

closing its individual manual shut-off valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than

1/2 (3447 PaG) psig. Refer to Figure 40.

GAS PIPING INSTALLATION

Properly sized wrought iron, approved flexible or steel pipe must be

used when making gas connections to the unit. If local codes allow the

use of a flexible gas appliance connection, always use a new listed con-

nector. Do not use a connector that has previously serviced another gas

appliance.

Some utility companies or local codes require pipe sizes larger than the

minimum sizes listed in these instructions and in the codes. The furnace

rating plate and the instructions in this section specify the type of gas

approved for this furnace - only use those approved gases.

IMPORTANT: An accessible manual shut-off valve must be installed

upstream of the furnace gas valve and within 6 feet (1.8 m) of the fur-

nace.

TESTING PIPING FOR LEAKS

Before turning on gas under pressure into piping, all openings from

which gas can escape should be closed. Immediately after turning on

gas, the system should be checked for leaks. This can be done by

watching the 1/2 cubic feet (0.14 m

3

) test dial and allowing 5 minutes to

show any movement, or by soaping each pipe connection and watching

for bubbles. If a leak is found, make the necessary repairs and repeat

the above test.

DEFFECTIVE PIPES OR FITTINGS SHOULD BE REPLACED AND

NOT REPAIRED. NEVER USE A FLAME OR FIRE

IN ANY FORM TO

LOCATE GAS LEAKS, USE A SOAP SOLUTION.

TABLE 16:

Gas Line Piping Size and Length

Length of Pipe in

Feet (Meter)

Nominal Diameter of Pipe in Inches (mm)

3/4 (19.05) 1 (25.4) 1-1/4 (31.75) 1-1/2 (38.1) 2 (50.8)

Capacity-Cu. Ft. (m

3

) Per Hr. with a 0.6 Sp. Gr. Gas and Pressure Drop of 0.3 in. (74.72 Pa) Water Col.

15 (4.572) 172 (4.87) 345 (9.77) 750 (21.24 — —

30 (9.144) 120 (3.4) 241 (6.82) 535 (15.15) 850 (24.07) —

45 (13.72) 99 (2.8) 199 (5.64) 435 (12.32) 700 (19.82) —

60 (18.29) 86 (2.44) 173 (4.90) 380 (10.76) 610 (17.27) —

75 (22.86) 77 (2.18) 155 (4.34) 345 (9.77) 545 (15.43) —

105 (32) 65 (1.84) 131 (3.71) 285 (8.07) 450 (12.74) 920 (26.05)

120 (36.58) — 120 (3.4) 270 (7.65) 420 (11.89) 860 (24.35)

180 (54.86) — 100 (2.83) 225 (6.37) 350 (10.76) 720 (20.39)

FIGURE 40: Manual Shut-off Valve/Gas Piping

Tee

Control

Manifold

Pipe Cap

Union

Direction

of Flow

3.00 Min.

(72.6)

Manual

Shutoff Valve

(Close this valve during pressure

testing of the gas line)

1/8” NPT Plugged

Tapping Pressure

Gauge Port

Floor Level

LOCATION OF UNION AND DRIP LEG FOR

CONNECTING BURNER TO HOUSING PIPING

Black

Iron Pipe

Drip

Leg

Gas Line

Shutoff

Valve

Gas Piping

From Meter

To Gas

Valve

TABLE 17:

Length of Standard Pipe Threads in Inches (mm)

PIPE SIZE

EFFECTIVE LENGTH

OF THREAD

OVERALL LENGTH

OF THREAD

3/8 (9.53) 3/8 (9.53) 9/16 (14.29)

1/2 (12.7) 1/2 (12.7) 3/4 (19.05)

3/4 (19.05) 1/2 - 9/16 (14.29) 13/16 (20.64)

1 (25.4) 9/16 (14.29) 1 (25.4)

FIGURE 41: Proper Piping Practice

If the gas input to the furnace is too great because of excessive

gas pressure, wrong size orifice, high altitude, etc., the burner

flame will be sooty and may produce carbon monoxide, which

could result in unsafe operation, explosion, and/or fire or

asphyxiation.

Leave 2 End

Threads Bare

2 Imprerfect

Threads