036-21359-001-B-0302

Unitary Products Group 17

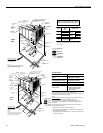

ELECTRICAL REQUIREMENTS

All unit power wiring shall enter unit cabinet at a single

factory provided location and be capable of side or bot-

tom entry, to minimize roof penetrations and avoid unit

field modifications. Separate side and bottom openings

shall be provided for the control wiring.

STANDARD LIMITED WARRANTIES

Compressor- 5 Years

Heat Exchanger - 10 Years

Elect. Heat. Elem.- 5 Years

Parts- 1 Year

OPTIONAL OUTDOOR AIR (Shall be made available

by either/or):

1 ELECTRONIC ENTHALPY AUTOMATIC ECON-

OMIZER - Outdoor and return air dampers that are

interlocked and positioned by a fully-modulating,

spring-return damper actuator. The maximum leak-

age rate for the outdoor air intake dampers shall

not exceed 2% when dampers are fully closed and

operating against a pressure differential of 0.5

IWG. A unit-mounted potentiometer shall be pro-

vided to adjust the outdoor and return air damper

assembly to take in CFM of outdoor air to meet the

minimum ventilation requirement of the conditioned

space during normal operation. During economizer

operation, a mixed-air temperature control shall

modulate the outdoor and return air damper

assembly to prevent the supply air temperature

from dropping below 55°F. Changeover from com-

pressor to economizer operation shall be provided

by an integral electronic enthalpy control that feeds

input into the basic module. The outdoor intake

opening shall be covered with a rain hood that

matches the exterior of the unit. Water eliminator/

filters shall be provided. Simultaneous economizer/

compressor operation is also possible. Dampers

shall fully close on power loss.

2. DUAL INPUT DIFFERENTIAL ELECTRONIC

ENTHALPY AUTOMATIC ECONOMIZER -Out-

door and return air dampers that are interlocked

and positioned by a fully-modulating, spring-return

damper actuator. The maximum leakage rate for

the outdoor air intake dampers shall not exceed

2% when dampers are fully closed and operating

against a pressure differential of 0.5 IWG. A unit

mounted potentiometer shall be provided to adjust

the outdoor and return air damper assembly to take

in the design CFM of outdoor air to meet the mini-

mum ventilation requirement of the conditioned

space during normal operation. During economizer

operation, a mixed-air temperature control shall

modulate the outdoor and return air damper

assembly to prevent the supply air temperature

from dropping below 55°F. Changeover from com-

pressor to economizer operation shall be provided

by two integral electronic enthalpy controls - one

that senses outdoor air and one that senses indoor

air. Both enthalpy sensors supply input to the logic

module which modulates both sets of dampers for

maximum economizer savings. The outdoor intake

opening shall be covered with a rain hood that

matches the exterior of the unit. Water eliminator/

filters shall be provided. Simultaneous economizer/

compressor operation is also possible. Dampers

shall fully close on power loss.

3 MOTORIZED OUTDOOR AIR DAMPERS -Out-

door and return air dampers that are interlocked

and positioned by a 2-position, spring-return

damper actuator. The maximum leakage rate for

the outdoor air intake dampers shall not exceed

2% when dampers are fully closed and operating

against a pressure differential of 0.5 IWG. A unit-

mounted potentiometer shall be provided to adjust

the outdoor and return air damper assembly to take

in the design CFM of outdoor air to meet the venti-

lation requirements of the conditioned space during

normal operation. Whenever the indoor fan motor

is energized, the dampers open up to one of two

pre-selected positions - regardless of the outdoor

air enthalpy. Dampers return to the fully closed

position when the indoor fan motor is de-ener-

gized. Dampers shall fully close on power loss.

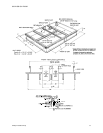

OTHER PRE-ENGINEERED ACCESSORIES AVAIL-

ABLE

1.

ROOF CURB - 14" high, full perimeter curb with

wood nailer (shipped knocked-down).

2.

BAROMETRIC RELIEF DAMPER -Containsarain

hood, air inlet screen, exhaust damper and mount-

ing hardware. Used to relieve internal air pressure

through the unit during economizer operation.

3.

PROPANE CONVERSION KIT - Contains new ori-

fices and gas valve parts to convert from natural to

L.P. gas. One per unit required.

4.

HIGH ALTITUDE - NATURAL GAS -Containsorifices

required for applications between 2000 and 6000

feet altitude.