036-21359-001-B-0302

Unitary Products Group 15

MECHANICAL SPECIFICATIONS

GENERAL DESCRIPTION

Units shall be factory-assembled, single packaged,

(DCG Electric Cooling/Gas Heat, DCE Electric Cooling/

Optional Electric Heat), designed for outdoor mounted

installation. Units shall have minimum EER ratings of

8.5. They shall have built in field convertible duct con-

nections for down discharge supply/return or horizontal

discharge supply/return, and be available with factory

installed options or field installed accessories.

The units shall be factory wired, piped, charged with R-

22 refrigerant and factory tested prior to shipment. All

unit wiring shall be both numbered and color coded.

Enclosed in each unit shall be a factory test log sheet

consisting of the unit tested pressures, temperatures

and amps, as tested prior to shipment.

All units shall be manufactured in a facility certified to

ISO 9001 standards and the cooling performance shall

be rated in accordance with DOE and ARI test proce-

dures. Units shall be ETL & CGA listed, classified to

ANSIZ21.47 standards, UL 1995/CAN/CSA No. 236-

M90 conditions.

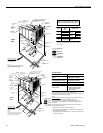

UNIT CABINET

1. Unit cabinet shall be constructed of G90 galva-

nizedsteel,withexteriorsurfacescoatedwitha

non-chalking, powered paint finish, certified at 750

hours salt spray test per ASTM-B117 standards.

2. Indoor blower section shall be insulated with up to

1" thick insulation, coated on the air side. Alumi-

num foil faced insulation shall be used in the fur-

nace compartment and be fastened with ridged

fasteners to prevent insulation from entering the air

stream.

3. Cabinet panels shall be “large” size, easily remov-

able for servicing and maintenance.

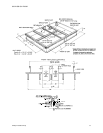

4. Full perimeter base rails shall be provided to

assure reliable transit of equipment, overhead rig-

ging and proper sealing on roof curb applications.

5. Disposable 2" filters shall be furnished and be

accessible through a removable access door,

sealed air tight. Units filter track shall be designed

to accommodate either 1" or 2" filters.

6. Fan performance measuring ports shall be pro-

vided on the outside of the cabinet to allow accu-

rate air measurements of evaporator fan

performance without removing panels or creating

air by-pass of the coils.

7. Condensate pan shall be internally sloped and

conform to ASHARE 62-89 self-draining standards.

Condensate connection shall be a minimum of 1"

I.D. female and be a ridged mount connection.

8. Unit shall incorporate a fixed outdoor air damper

with an outdoor air intake opening covered with a

bird screen and a rain hood painted to match the

exterior of the unit.

INDOOR (EVAPORATOR) FAN ASSEMBLY

1. Fan shall be a belt drive assembly and include an

adjustable-pitch motor pulley. Job site selected

(B.H.P.) brake horse power shall not exceed the

motors nameplate horse power rating, plus the ser-

vice factor. Units shall be designed not to operate

above service factor.

2. Fan wheel shall be double-inlet type with forward-

curved blades, dynamically balanced to operate

smoothly throughout the entire range of operation.

Airflow design shall be constant air volume.

3. Bearings shall be sealed and permanently lubri-

cated for longer life and no maintenance.

OUTDOOR (CONDENSER) FAN ASSEMBLY

1. The outdoor fans shall be of the direct-driven pro-

peller type, discharge air vertically, have blades

riveted to corrosion resistant steel spider brackets

and shall be dynamically balanced for smooth

operation.

2. The 2 outdoor fan motors shall be totally enclosed

with permanently lubricated bearings, internally

protected against overload conditions and staged

independently.

REFRIGERANT COMPONENTS

1. Compressors:

A. Shall be fully hermetic type, direct drive, internally

protected with internal high-pressure relief and over

temperature protection. The hermetic motor shall be

suction gas cooled and have a voltage range of + or

- 10% of the unit nameplate voltage.

B. Shall have internal spring isolation and sound muf-

fling to minimize vibration and noise, and be exter-

nally isolated on a dedicated, independent

mounting.

2Coils:

A. Evaporator and condenser coils shall have alumi-

num plate fins mechanically bonded to seamless

internally-enhanced copper tubes with all joints

brazed. Special Phenolic coating shall be available

as a factory option.