Gas Supply & Piping (cont.)

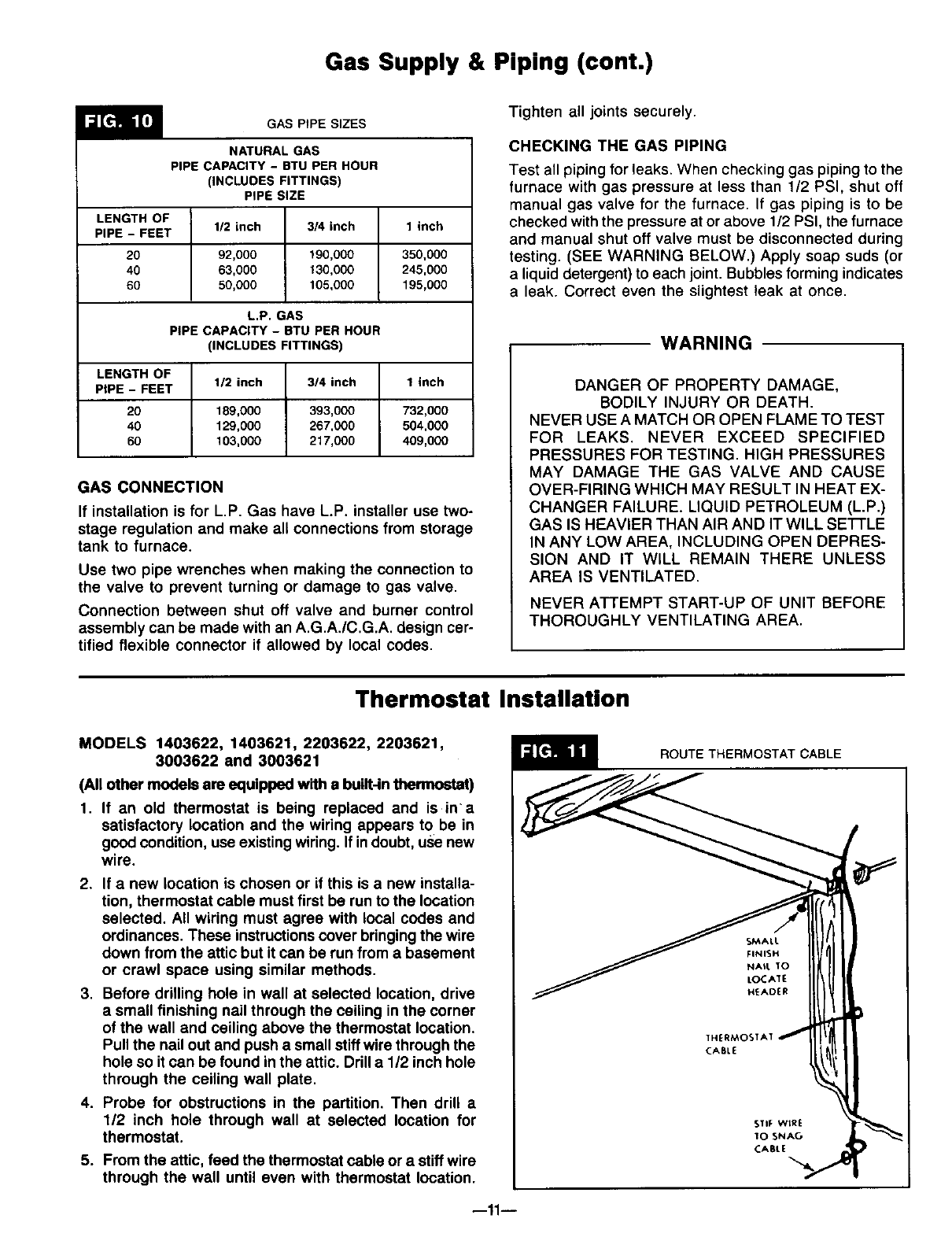

GAS PtPE SIZES

NATURAL GAS

PIPE CAPACITY - BTU PER HOUR

(INCLUDES FITTINGS)

PIPE SIZE

LENGTH OF

PIPE - FEET 1/2 inch 3/4 inch 1 inch

20 92,000 190,000 350,000

40 63,000 130,000 245,000

60 50,000 105,000 195,000

L.P. GAS

PIPE CAPACITY - BTU PER HOUR

(INCLUDES FITTINGS)

LENGTH OF

PIPE - FEET 112 inch 3/4 inch 1 inch

20 189,000 393,000 732,000

40 129,000 267,000 504,000

60 103,000 217,000 409,000

GAS CONNECTION

If installation is for L.P. Gas have L.P. installer use two-

stage regulation and make all connections from storage

tank to furnace.

Use two pipe wrenches when making the connection to

the valve to prevent turning or damage to gas valve.

Connection between shut off valve and burner control

assembly can be made with an A.G.A./C.G.A. design cer-

tified flexible connector if allowed by local codes.

Tighten all joints securely.

CHECKING THE GAS PIPING

Test all piping for leaks. When checking gas piping to the

furnace with gas pressure at less than 1/2 PSI, shut off

manual gas valve for the furnace. If gas piping is to be

checked with the pressure at or above 1/2 PSI, the furnace

and manual shut off valve must be disconnected during

testing. (SEE WARNING BELOW.) Apply soap suds (or

a liquid detergent) to each joint. Bubbles forming indicates

a leak. Correct even the slightest leak at once.

WARNING

DANGER OF PROPERTY DAMAGE,

BODILY INJURY OR DEATH.

NEVER USE A MATCH OR OPEN FLAME TO TEST

FOR LEAKS. NEVER EXCEED SPECIFIED

PRESSURES FOR TESTING. HIGH PRESSURES

MAY DAMAGE THE GAS VALVE AND CAUSE

OVER-FIRING WHICH MAY RESULT IN HEAT EX-

CHANGER FAILURE. LIQUID PETROLEUM (L.P.)

GAS IS HEAVIER THAN AIR AND IT WILL SE'I-FLE

IN ANY LOW AREA, INCLUDING OPEN DEPRES-

SION AND IT WILL REMAIN THERE UNLESS

AREA IS VENTILATED.

NEVER ATTEMPT START-UP OF UNIT BEFORE

THOROUGHLY VENTILATING AREA.

Thermostat Installation

MODELS 1403622, 1403621, 2203622, 2203621,

3003622 and 3003621

(All other models are equipped with a built-in thermostat)

1. If an old thermostat is being replaced and is in'a

satisfactory location and the wiring appears to be in

good condition, use existing wiring. If indoubt, use new

wire.

2. If a new location is chosen or if this is a new installa-

tion, thermostat cable must first be run to the location

selected. All wiring must agree with local codes and

ordinances. These instructions cover bringing the wire

down from the attic but it can be run from a basement

or crawl space using similar methods.

3. Before drilling hole in wall at selected location, drive

a small finishing nail through the ceiling in the corner

of the wall and ceiling above the thermostat location.

Pull the nail out and push a small stiffwire through the

hole so itcan be found in the attic. Drill a 1/2 inch hole

through the ceiling wall plate.

4. Probe for obstructions in the partition. Then drill a

112 inch hole through wall at selected location for

thermostat.

5. From the attic, feed the thermostat cable or a stiff wire

through the wall until even with thermostat location.

ROUTE THERMOSTAT CABLE

SMAL I.

FINISH

NAi l, 10

LOCATE

H_ADER

CABL[

STIF WtRE

10 SNAG

CABLE

--11 m