Fiberglass wool and ceramic fiber materials:

• POSSIBLE CANCER HAZARD

BY INHALATION

• CAN CAUSE RESPIRATORY,

SKIN AND EYE IRRITATION

This product contains fiberglass wool and ceramic

fiber materials. Airborne fibers from these materials

have been listed by the State of California as a

possible cause of cancer through inhalation. Apply

special care when handling ceramic fiber (chamber

lining, base insulation) materials. Ceramic fibers can

be converted to chrystobalites, a substance listed as a

probable cause of cancer.

Suppliers of fiberglass wool products recommend

the following precautions be taken when handling

these materials:

Precautionary measures:

• Avoid breathing fiberglass dust and contact

with skin and eyes.

• Use NIOSH approved dust/mist respirator.

• Wear long-sleeved, loose fitting clothing, gloves

and eye protection.

• Wash work clothes separately from other

clothing. Rinse washer thoroughly.

• Operations such as sawing, blowing, tearout

and spraying may generate airborne fiber

concentration requiring additional protection.

First aid measures:

• Eye contact — Flush eyes with water to remove

dust. If symptoms persist, seek medical attention.

• Skin contact — Wash affected areas gently

with soap and warm water after handling.

Place boiler:

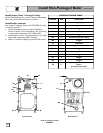

1. A-SGO-3 through 6W — position on site.

Smaller-sized boilers may be top

heavy. Use caution when

handling to avoid minor personal injury or

property damage.

a. Boiler is shipped for back flue outlet.

To change to top flue outlet (see FIGURE 2):

1) Loosen two screws holding flue cap strap

to collector hood. Remove strap and flue

cap from opening. Re-tighten screws.

2) Check rope placement inside flue cap.

(Read under Step #3 on

page 7.)

3) Loosen two screws on back flue outlet. Set

flue cap on outlet. Install strap by

engaging slots in screws. Tighten screws.

Make sure cap is securely installed.

2. A-SGO-7, 8 & 9W— split the assembled block

for easier handling (see FIGURE 2):

a. Open burner mounting door and,

using utility knife, slit floor insulation at

joint to be separated.

b. Remove 5½" draw rod and the longest draw

rod from each side. Pull block apart. Save

draw rods, nuts, washers and sealing rings

for reassembly.

c. Move divided block to location.

d. Clean port openings with clean rag.

Do not use petroleum-based

compounds to clean

openings. Damage to system components

can result, causing property damage.

e. Place rings in port openings. If ring slips out

of groove, stretch ring gently for several

seconds, then place in groove.

f. Position sections so aligning lugs fit into

sockets of next section. Make sure sealing

rope is in good condition and in position.

g. Oil threads on draw rods. Install washer

and nut on end to be tightened. Use nut

only on other end.

h. With wrench at washer/nut end,

uniformly tighten nuts starting with 5½"

rod at large port, 5½" rod at small port,

bottom long rod and finally top long rod.

i. Torque on both 5½" rods and bottom

long rod should be 50-60 ft. lbs; long

top rod should be 20-25 ft. lbs. Do not

back-off nuts.

j. Metal-to-metal contact should be

made around port openings. If gap

does exist, it should be less than .020".

Check with feeler gauge.

k. If gap around port openings exceeds .020",

check for dirt on port openings, sockets or

misaligned lugs. If corrections are made

and gap still exists, contact your

Weil-McLain distributor or sales office

before continuing installation.

6

Install Non-Packaged Boiler