AlumiPex Radiant Tubing

Part Number 650-000-221/0298

14

I. Install the Tubing

1. Install the sleepers.

Beginning from one side of each room, use your

floor markings and the tube layout drawing to

place the sleepers.

Glue and nail each sleeper in place as shown in

Figure 10.

Bend routing sleepers can be made using a router

and fixture as shown or using a saber saw to cut

semicircles.

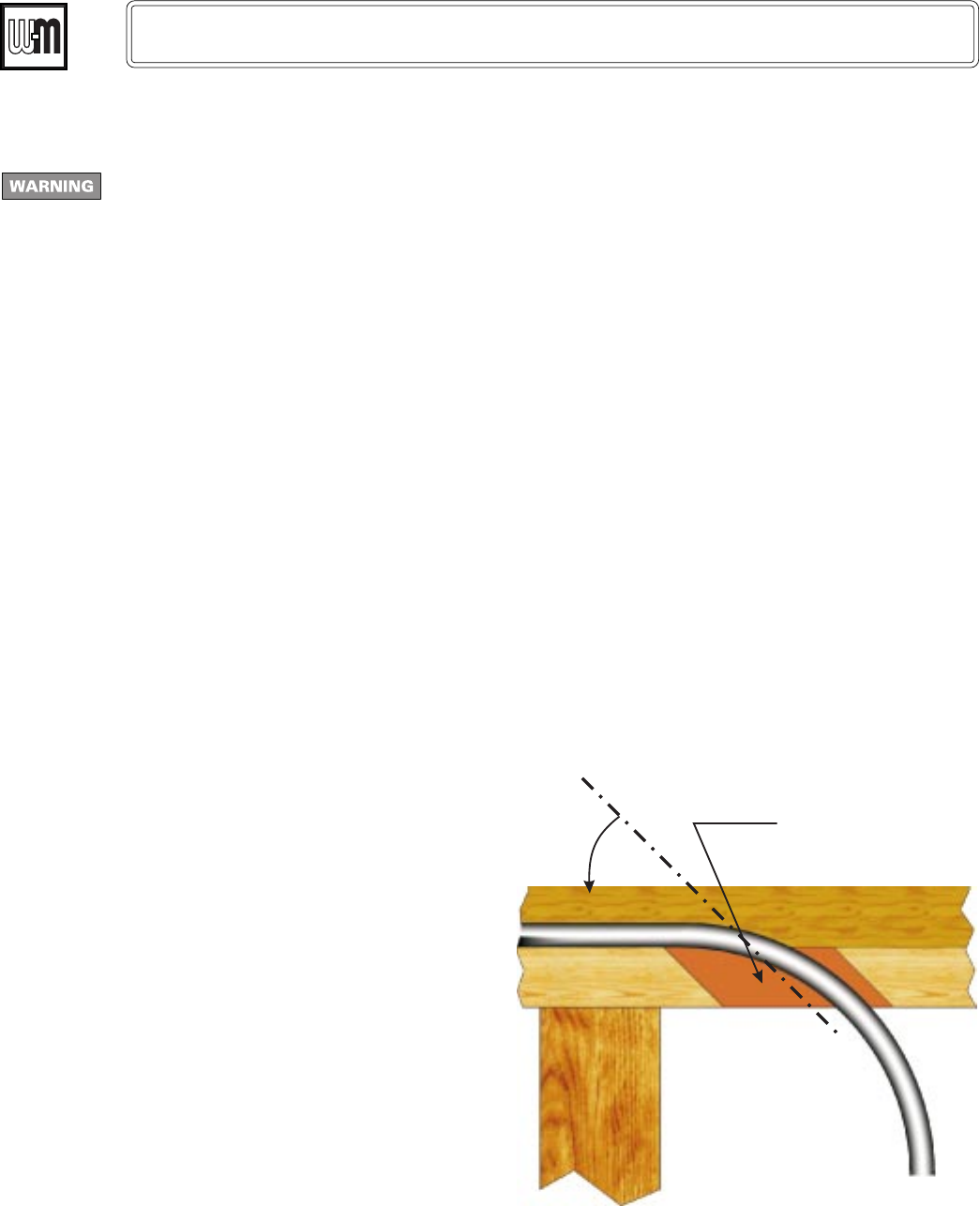

2. Drill tube penetration holes.

If the tubing will penetrate the floor in the room,

drill a 1½” hole at a 45 degree angle for each

penetration as shown in Figure 9.

Make sure the tube can be routed through the hole

from below and provide a minimum 6 inch bend

diameter (3 inch bend radius) for 1/2” tubing.

3. Install heat emission plates.

Install AlumiPex Heat Emission Plates in the

sleeper spaces, centered in the 1” gap.

Secure heat emission plates on one side only to the

sleeper below using 5/8” staples.

Leave the other side of the heat emission plates

free to move so the plates can conform to the floor

as the upper subfloor or finished flooring is

installed.

See Figure 11 for typical details.

4. Place tube roll on uncoiler.

5. Route free end of tubing to manifold.

Feed the free end of the tubing through any

penetration holes to the manifold.

6. Install manifold fitting on free end of tube.

a. AlumiPex Nickel-Plated Brass Manifolds:

Use only AlumiPex Euro conical fittings.

Refer to AlumiPex Manifold Instructions for

details and part numbers.

b. AlumiPex Copper Manifolds:

Use only AlumiPex tubing to NPT connectors.

7. Attach tube fitting to manifold SUPPLY connection

(bottom manifold).

8. Feed the tubing to the room as shown on the heating

system designer’s tube layout drawing, feeding the

outer (SUPPLY) tubing first.

9. Complete the layout for the circuit and route the

tubing back to the return manifold as shown on the

tube layout drawing.

10. Carefully cut the tubing to the correct height at the

return manifold. Apply an AlumiPex fitting for

attachment to the manifold.

11. Then attach the fitting to the RETURN (top) manifold.

12. Continue the process for each circuit.

13. See Figure 11, page 16, for an above floor

construction example.

Always wear safety glasses for eye protection

when handling AlumiPex tubing. The tubing

can spring back when pulled. Failure to follow

this guideline could result in serious personal

injury.

Figure 9 - Tubing penetration hole, typical

Joist, Typical

1/2" Tubing, Typical

(With 6" bend diameter)

Drill penetration holes

1½" diameter on 45

degree angle.

SubfloorSubfloor

SleeperSleeper

45

degrees