WM 550-141-996/1105 Page 9

RWB 6104WMNX R1005

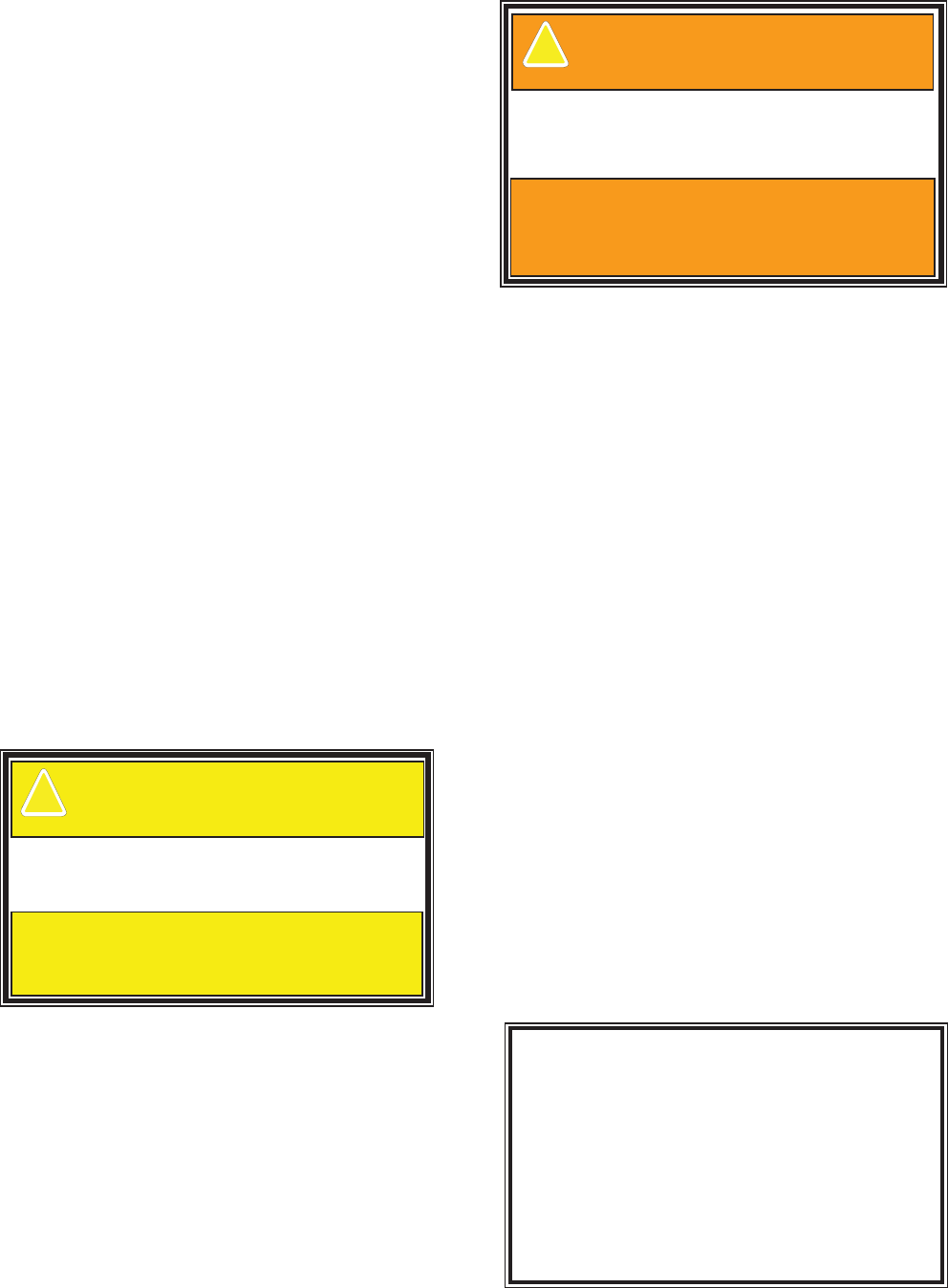

Warning – By-pass Plug in

2 Pipe System

The burner pump is shipped without the by-pass plug

installed. You must install this plug on two-pipe oil

systems. If the unit is a one-pipe oil system DO NOT

install the plug in the pump.

Failure to comply could cause pump

seal failure, oil leakage and the

potential for a fire and injury hazard.

S110

!

Prepare the Burner

General

In most cases, the burner is ready to mount to the

appliance. There can be situations where the burn-

er needs to be reconfi gured to perform properly in

the appliance. Review the appliance manufactur-

er’s specifi cations prior to installing to determine if

any modifi cation is required to properly confi gure

the burner. Refer to Table 1.

Instruction on how to perform the following burner

preparation tasks can be found in the Professional

Maintenance section.

Remove / install burner nozzle

Check head/air adjusting plate

Mount Burner on Appliance

Verify that the air tube installed on the burner pro-

vides the correct insertion depth. Bolt the burner

to the appliance using the factory-welded fl ange.

Note that the end of the tube will extend into the

chamber on UO-4 and UO-5 boilers.

Connect Fuel Lines

The burner is supplied with either a one-stage

pump or a two-stage pump based on the oil supply

system requirements. Consult the instructions pro-

vided with the pump for installation specifi cations.

•

•

•

•

•

When installing a two-pipe system, remove the

1/16” pipe by-pass plug from plastic bag attached

to fuel unit. Remove ¼” plug from return port. In-

sert and tighten the by-pass plug. Attach return

and inlet lines. Start burner. Air bleeding is au-

tomatic. Open the easy fl ow air bleed valve for a

faster bleed, if desired. The return line should ter-

minate approximately 3-4” above supply line inlet.

Failure to do this may introduce air into the system

and could result in loss of prime.

Wiring Connection Diagram

Burner wiring performed at jobsite: Refer to Figure

3, for typical burner interconnect wiring, Burner

wiring may vary, depending on the burner specifi -

cation. Refer to Figure 4 for burner wiring details.

All wiring must be in accordance with the latest re-

vision of National Electric Code NFPA 70 and all

local codes and regulations.

The R7184 primary control with valve-on delay and

burner motor-off delay, shown in Figure 4, requires

a constant 120 volt AC power source supplied to

the black wire on the control. The red wire goes

to the appliance limit circuit. Please note that other

control manufacturers may use different wire colors

for power and limit connections.

•

Caution–Oil Supply

Pressure Control Required

The oil supply inlet pressure to the fuel unit cannot exceed

3 psi. Insure that a pressure-limiting device is installed in

accordance with the latest edition of the NFPA 31.

Damage to Pump Seal could cause

possible oil leakage and potential

fire hazard.

S109

!

Burner Preparation

When installing a one-pipe system, connect the

inlet line to the pump inlet. Start the burner. Ar-

range the primary burner control for continuous op-

eration during priming by pressing the control reset

button during prepurge. Open the bleed valve one

turn counterclockwise. Prime the system until all

air bubbles have disappeared. Tighten the bleed

valve securely.

The fuel pump may be installed with gravity feed

or lift. The maximum allowable lift for a single pipe

installation is 8 ft.

NOTICE

The NX burner has a reduced diameter air tube,

precision-designed air throttle cup and combus-

tion head for improved performance. This de-

sign provides very accurate control of the air/fuel

ratio, but the light reaching the cad cell through

small holes in these components is limited. Be-

cause of this, the average cad cell resistance

may be higher than conventional burners

with larger openings.