Page 12 WM 550-141-996/1105

RWB 6104WMNX R1005

Start the Burner and Set Combustion

Start-up and Initial Settings

Open the shutoff valves in the oil supply line to

the burner.

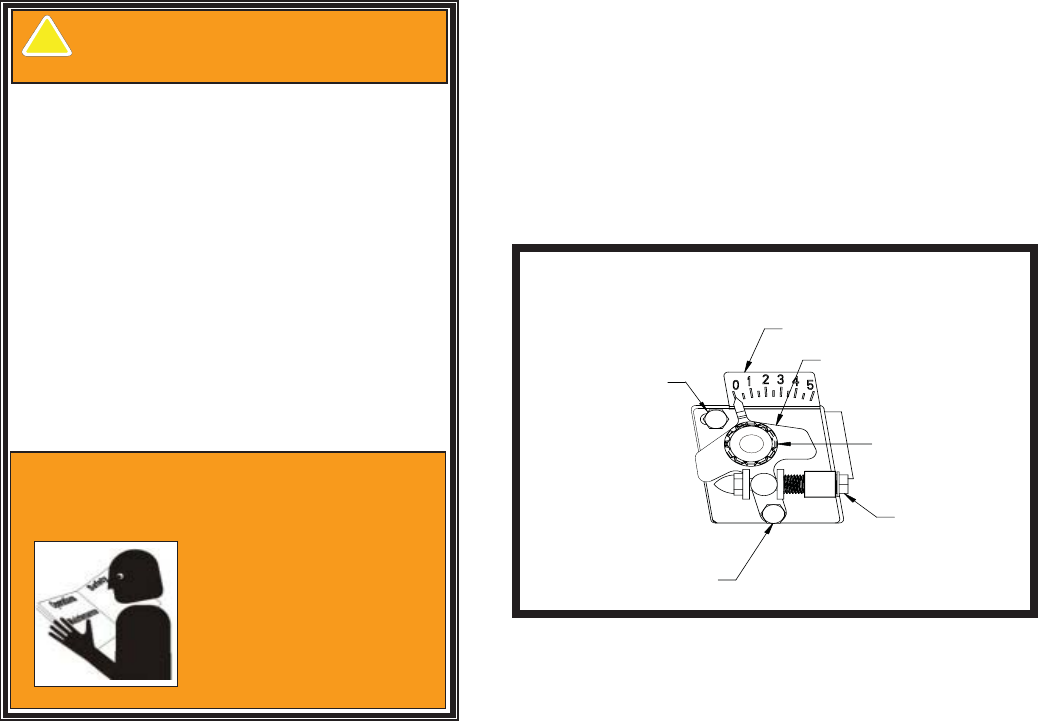

Referencing Figure 5 verify and/or set the Head/

Air Adjustment Pointer to the value shown in

Table 1. This is an initial air setting for the pump

bleeding procedure only. Calibrated test instru-

ments must be used for the fi nal head/air adjust-

ment.

Set the thermostat substantially above room

temperature.

Close the line voltage switch to start the burner.

If the burner does not start within the 3 to 10

second safety start check timing, you may have

to reset the safety switch on the burner primary

control.

Bleed the air from the fuel pump as soon as the

burner motor begins rotating.

•

1.

2.

3.

4.

5.

Warning–Professional

Service Required

This equipment must be installed, adjusted and put into

operation only by a qualified individual or service agency

that is:

x Licensed or certified to install and provide technical

service to oil heating systems.

x Experienced with all applicable codes, standards and

ordinances

x Responsible for the correct installation and

commission of this equipment

x Skilled in the adjustment of oil burners using

combustion test instruments.

The installation must strictly comply with all applicable

codes, authorities having jurisdiction and the latest

revision of the National Fire Protection Association

Standard for the Installation of Oil-Burning Equipment,

NFPA 31 (or CSA B139 and B140 in Canada).

Regulation by these authorities take precedence over the

general instructions provided in this installation manual.

S105

Read and understand the manual

supplied with this equipment. Incorrect

installation, adjustment, and use of

this burner may result in

severe personal injury

death, or substantial

property damage from

fire, carbon monoxide

poisoning, soot or

ex

p

losion.

!

Figure 5. – Head/air Adjustment Plate

Assembly

Upper Acorn Nut

(Lock Zero

Calibration)

Lower Acorn Nut

(Lock Air Setting)

Scale

Pointer

Splined

Nut

Adjustment

Nut

SK9667

Start the Burner

Step 1: To bleed the fuel pump, attach a clear

plastic hose over the vent fi tting. Loosen the fi t-

ting and catch the oil in an empty container. Tight-

en the fi tting when all the air has been purged

from the oil supply system.

Step 2: If the burner locks-out on safety during

bleeding, reset the safety switch and complete

the bleeding procedure. Note — For R7184 pri-

mary controls, see Technician’s Quick Reference

Guide, part number 61351 or 61465, for special

pump priming sequence.

Step 3: If the burner stops after a fl ame is estab-

lished, additional bleeding is probably required.

Repeat the bleeding procedure until the pump is

primed and a fl ame is established when the vent

fi tting is closed.

Prepare for combustion tests by drilling a

1/4

”

sampling hole in the fl ue pipe between the appli-

ance and the barometric draft regulator. Seal this

hole when testing is complete. (See appliance

manufacturer for location.)

Loosen the splined nut approximately one turn.

(DO NOT loosen the upper acorn nut. This is

used only for setting the zero adjustment.) (See

Figure 5.)

A 5/16” nut driver or fl at blade screwdriver can

be used to turn the adjustment screw for head/air

setting.

6.

7.

8.