Page 16 WM 550-141-996/1105

RWB 6104WMNX R1005

Check/Adjust Electrodes

Check the electrode tip settings, as shown in Fig-

ure 7. If necessary, adjust by loosening the elec-

trode clamp screw (Figure 8) and slide/rotate the

electrodes as necessary. When the adjustment is

complete, securely tighten the clamp screw.

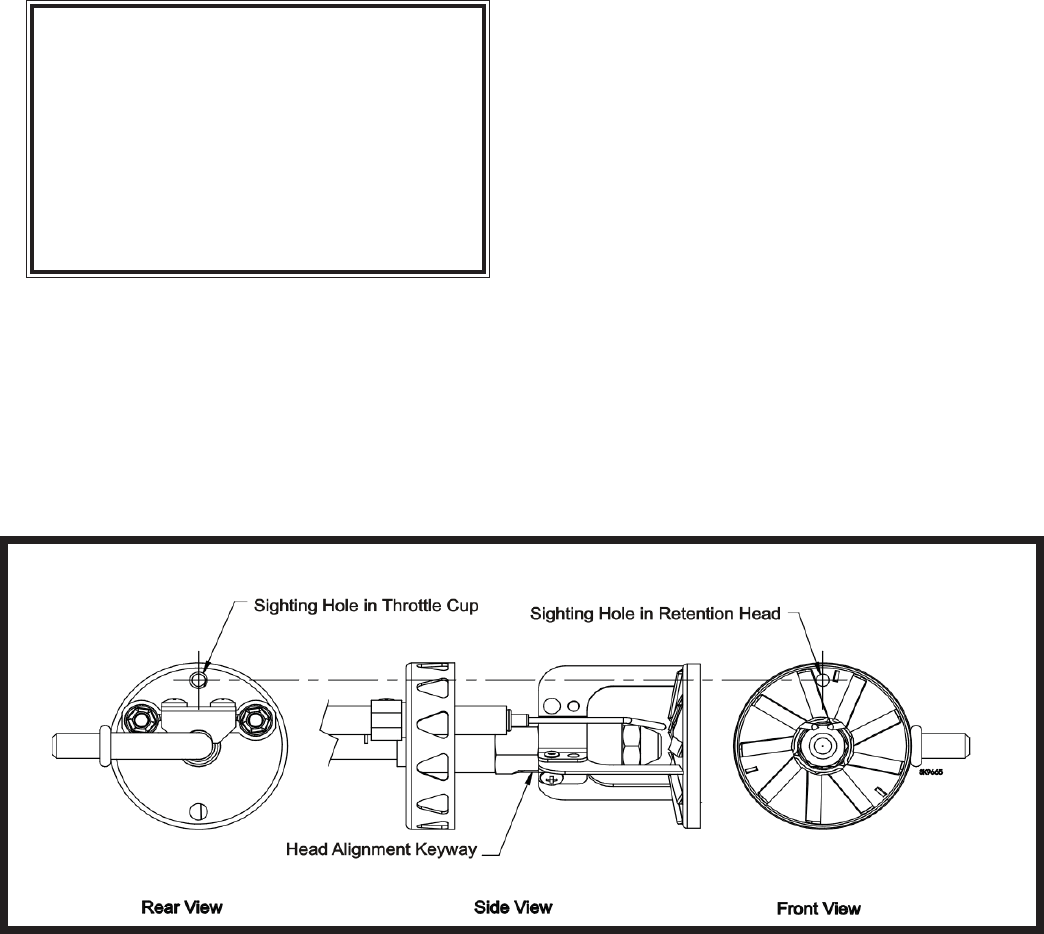

Check Retention Head Alignment and Cad

Cell Sighting (Refer to Figure 9.)

The cad cell sighting holes in both the throttle cup

and the retention head must be aligned to allow the

cad cell to detect the fl ame. Make sure the stamped

key in the retention head collar lines up with the

keyway in the nozzle adapter when mounting the

retention head.

•

•

If the zero calibration has not been set, perform the

following procedure:

Install the nozzle line, with the adjustment plate

assembly attached, into the burner.

Install and tighten the rear door to hold the air

adjustment plate assembly in position.

Slightly loosen the upper acorn nut, the splined

nut, and the lower acorn nut.

Turn the air adjustment screw clockwise to adjust

the plate with the pointer to the zero position.

Referring to Figure 8, slide the nozzle line as-

sembly forward until the retention head engages

the fi xed stops in the retention ring at the end of

the air tube.

Tighten the upper acorn nut securely.

The rear door must be kept tightly closed. The

adjustment screw may now be turned to adjust

the head/air setting.

Turn the adjusting screw to a setting ½ number

lower than the proper set point as indicated in

Table 1. Then turn the adjusting screw counter-

clockwise to the proper setting.

Tighten the splined nut and lower acorn nut after

the head/air setting has been adjusted.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Professional Maintenance

SK9665

Figure 9 – Retention Head/Throttle Cup Alignment

NOTICE

The NX burner has a reduced diameter air tube,

precision-designed air throttle cup and combus-

tion head for improved performance. This de-

sign provides very accurate control of the air/fuel

ratio, but the light reaching the cad cell through

small holes in these components is limited. Be-

cause of this, the average cad cell resistance

may be higher than conventional burners

with larger openings.

Check/Adjust “Zero” Calibration

On burners with factory-installed air tubes, the

zero calibration has been factory set. Make sure

the retention head (Figure 8) is securely against

the stops in the retention ring when the adjustment

plate pointer is at “0” (Figure 5).

•