Weil-McLain 78 Boiler For Gas, Light Oil, Gas/Light Oil Fired Burners

Assemble Block

3e

Prepare flue collector hood

assembly:

Make sure gaskets are intact, not torn or

otherwise damaged. These conditions can

cause possible flue gas leakage and carbon

monoxide emissions, resulting in severe

personal injury or death.

1. Stand one collector hood module on end.

2. Wipe all flanged surfaces with clean rag.

3. Lay gasket on flange. Refer to Figure 8.

4. Place end cap on gasket, aligning flanged

surfaces. Secure with six 5/16" x 5/8" flanged

bolts and flanged nuts. Tighten to 30 - 35 in.-

lbs.

5. For 878 - 1278:

a. Stand remaining hood module on end.

b. Wipe all flanged surfaces with clean rag.

c. Lay gasket on flange.

d. Carefully place open end of first module on

top of gasket, aligning flanged surfaces.

e. Secure with six 5/16" x 5/8" flanged bolts

and flanged nuts.

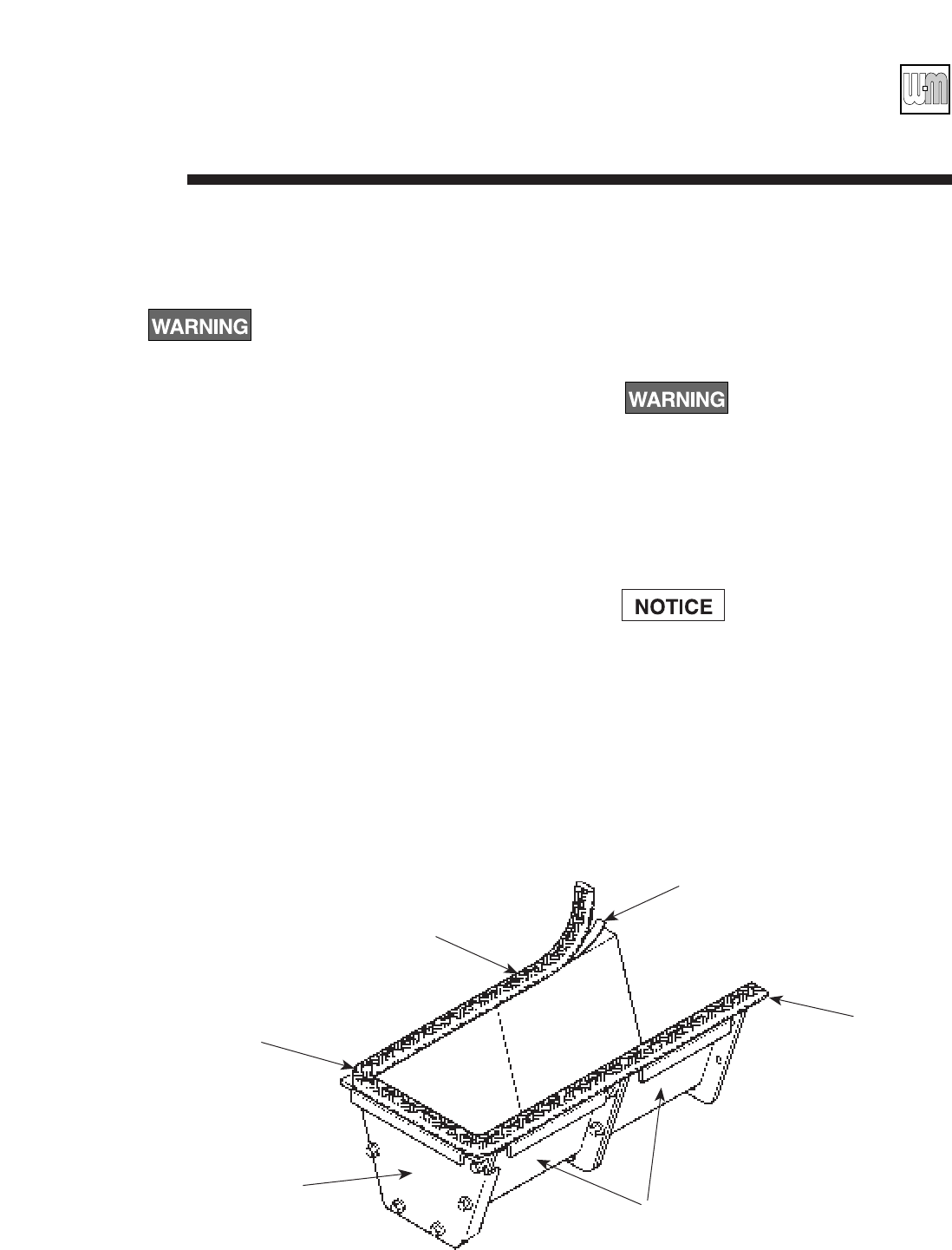

6. Attach flat-stitched sealing rope to hood

assembly. See Figure 9:

a. Lay hood on floor with flanged side up.

b. Wipe flanged surface with clean rag to

remove dirt and oil.

c. Apply double-faced tape to flanged surface.

d. Apply rope to tape beginning on one side of

open end of hood, leaving 1/4" extending

past edge. Around corners, bend rope, do not

cut. Do not stretch rope.

Do not pre-cut rope. Gas-tight

seal must be maintained to

prevent possible flue gas leakage

and carbon monoxide emissions,

resulting in severe personal

injury or death.

e. Continue around entire flange. At other open

end, leave 1/4" rope extending past edge of

flange. Cut off excess rope.

Double-faced tape serves only to

hold sealing rope in place during

installation. It will disintegrate

over time. If collector hood and

sealing rope is removed for any

reason, new tape and new gasket

must be applied.

Part No. 550-141-705

10

Flat-stitched

sealing rope

Bend rope do not

cut or stretch

Flue collector

hood modules

Extend rope 1/4"

past open ends

Double-faced

tape applied to

flange

Flue collector

hood end cap

Figure 9 Sealing Rope Application on Collector Hood Assembly