Part number 550-110-260/0200

24

GOLD CGs Gas-Fired Water Boiler

Gas piping5

Connecting gas supply piping to boiler

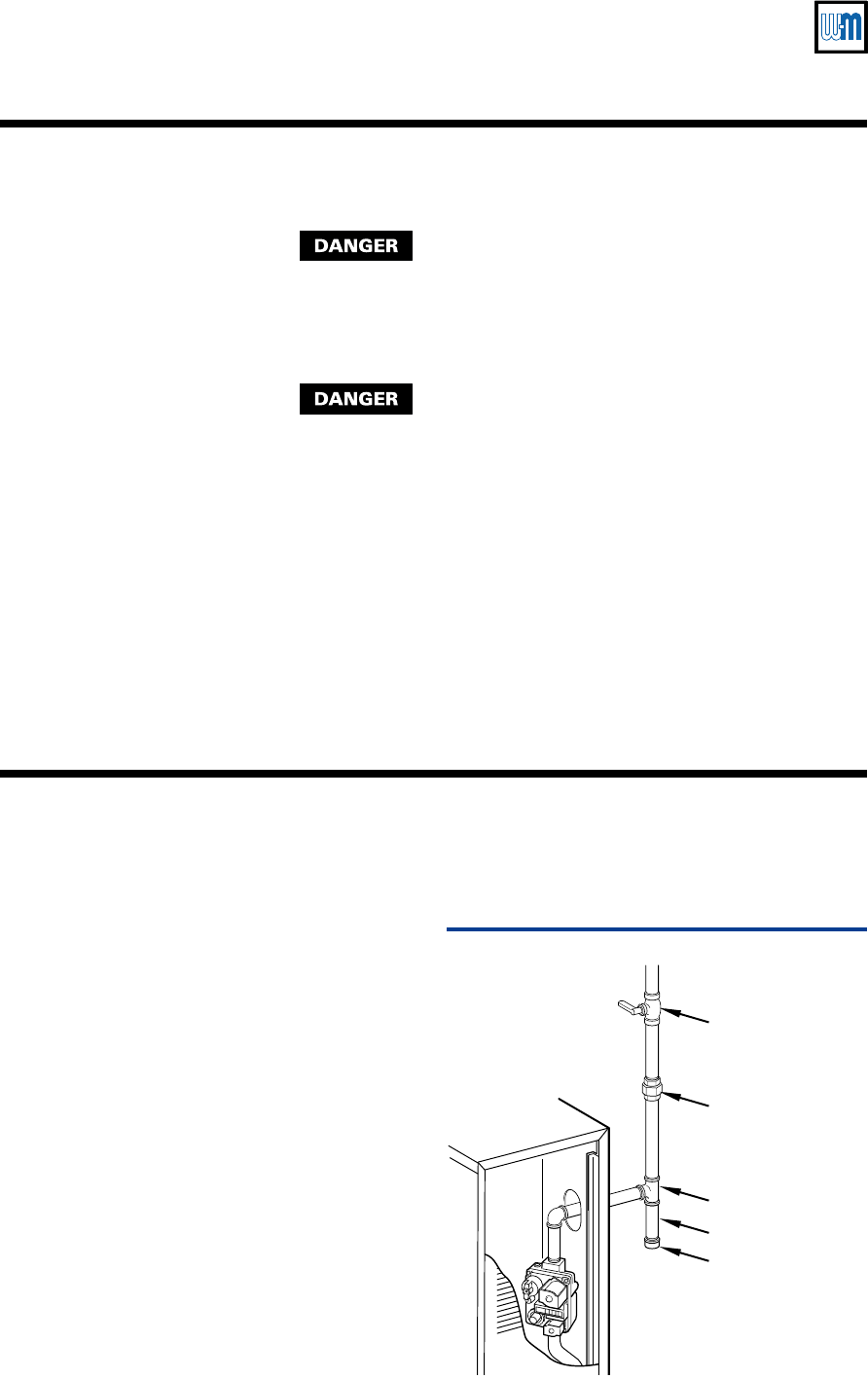

Figure 14 Gas supply piping

Venting and combustion air4

CGs Boiler must be vented and supplied with

combustion and ventilation air

as described in

Weil-McLain CGs Venting Supplements packed in

envelope assembly with boiler. Failure to do so will

cause severe personal injury or death.

Use direct vent (sealed combustion) if combustion

air quality cannot be assured to be free of

contaminants. Refer to page 9 for a list of potential

contaminants and locations likely to contain them.

Operating the boiler with contaminated air will damage

the boiler sections and vent, resulting in possible boiler

failure or leakage of flue products, causing severe

personal injury, death or substantial property damage.

Install vent piping and air piping

(if used) per appropriate Venting

Supplement included in boiler

envelope assembly.

Refer to Venting Supplements and

to manual section 1 regarding

requirements for:

• vent system

• combustion air openings

• combustion air quality

1. Remove jacket front panel and refer to

Figure 14

to pipe gas to boiler.

a. Install drip leg at inlet of gas connection to

boiler. Where local utility requires drip leg to

be extended to the floor, use appropriate length

of pipe between cap and tee.

b. Install ground joint union for servicing, when

required.

c. Install manual shutoff valve in gas supply

piping outside boiler jacket when required by

local codes or utility requirements.

d. In Canada — When using manual main shutoff

valve, it must be identified by the installer.

26020

Manual main

shutoff gas valve

(when required)

Ground joint union

(when required)

Nipple

Tee

Cap