Part number 550-110-260/0200

15

Boiler Manual

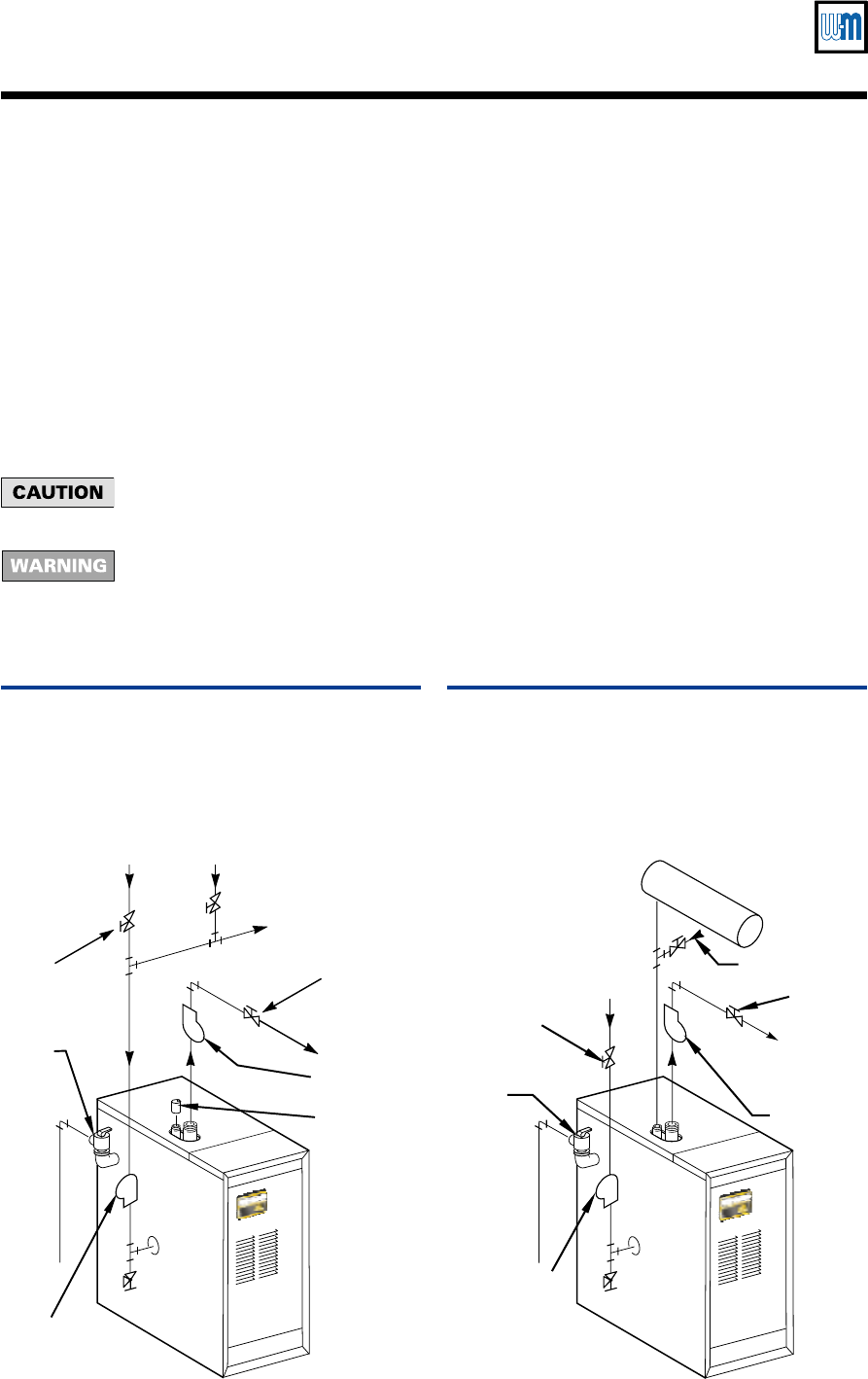

Water piping — single-zone system3b

Expansion tank

Diaphragm-type or bladder-type

expansion tank — Figure 4

1. Ensure expansion tank size will handle boiler and

system water volume and temperature. Tank must

be located in boiler return piping as close to boiler

as possible, before inlet side of circulator. See tank

manufacturer’s instructions for details.

2. Install an

automatic air vent in air vent tapping as

shown.

Figure 4 Diaphragm- or bladder-type expansion tank

Piping to single-zone system using

diaphragm-type or bladder-type expansion

tank. See Table 3 for piping sizes.

Figure 5 Closed-type expansion tank

Piping to single-zone system using closed-

type expansion tank. See Table 3 for piping

sizes.

Closed-type expansion tank —

Figure 5

1. Ensure expansion tank size will handle boiler and

system water volume and temperature. See tank

manufacturer’s instructions for details.

2. Connect tank to ½" NPT tapping located behind

supply outlet, using ½" NPT piping. Pitch any

horizontal piping up towards tank 1 inch per 5 feet

of piping.

Use Figure 4 or Figure 5 only for single-zone systems designed for return water at least 130 °F.

For systems with low return water temperature possible, such as converted gravity systems

and radiant heating systems, refer to the special piping suggestions of pages 18-23. Failure to

prevent low return water temperature to the boiler could cause corrosion of the boiler sections

or burners, resulting in severe personal injury, death or substantial property damage.

26010

From

system

Cold

water

fill

To DIAPHRAGM

expansion tank

and fittings

Isolation

valve

Isolation

valve

To system

Circulator*

Circulator

Drain

valve

Relief

valve

Automatic

air vent

*Alternate

location

26011

To system

From

system

Isolation

valve

Drain

valve

Relief

valve

Circulator*

Isolation

valve

Circulator

Cold water fill

CLOSED-type

expansion tank

*Alternate

location

Undersized expansion tanks cause system water to be lost from relief valve and makeup water

to be added through fill valve. Eventual section failure can result.