Part number 550-110-260/0200

23

Boiler Manual

3 System or zone circulator

7 System temperature valves (see instructions to the left for

adjusting valves)

8 Blend temperature gauge

9 Relief valve

10 Automatic air vent (with diaphragm-type expansion

tank), or connect to tank fitting (closed-type expansion

tank). DO NOT use an automatic air vent when using

closed-type expansion tank. It would allow air to leave

the system, causing waterlogging of the expansion tank.

11 Fill valve

12 Diaphragm-type or bladder-type expansion tank, if used

(For closed-type expansion tank, pipe from top of air

separator to tank fitting as in Figure 5.)

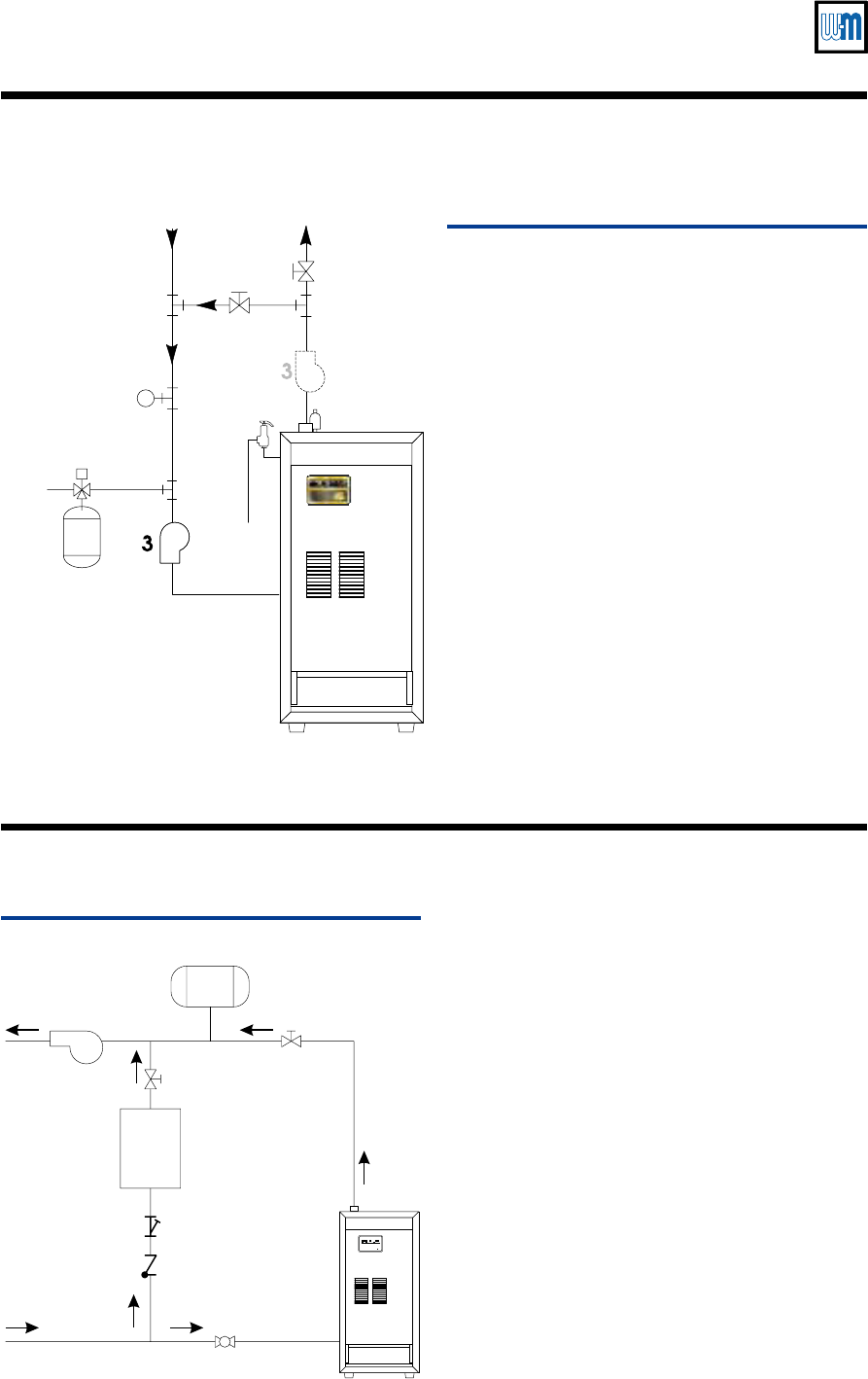

system-bypass (alternate) piping —

for converted gravity (or steam) systems

Figure 12 System-bypass piping

Zoning with zone valve or circulators, return

water 130 °F or higher.

(Alternative to boiler-bypass piping

Figures 10 and 11)

Figure 13 Piping refrigeration systems

Prevent chilled water from

entering boiler

Water piping — refrigeration system3g

26018

10

Cold

water

fill

11

12

9

8

7a

7b

Alternate

circulator

location

To systemFrom system

26019

Water

chiller

Expansion tank

Circulator

Check

valve

Strainer

Boiler

Shut-off

valve

System

supply

System

return

Balancing

valve

MODEL

CGs

Install boiler so that chilled

medium is piped in parallel with

the heating boiler. Use appropriate

valves to prevent chilled medium

from entering boiler. See

Figure 13

for typical installation of balancing

valve and check valve.

If boiler is connected to heating

coils located in air handling units

where they can be exposed to

refrigerated air, use flow control

valves or other automatic means to

prevent gravity circulation during

cooling cycle.

3f