Operating Instructions

4

for efficient operation.

5. Avoid overtightening of check valve

after cleaning. (Refer to

Maintenance gudelines.)

6. Use constant voltage power source.

Do not plug into a device that runs

intermittently.

7. Locate model number and date

code on pump and take note of

them.

8. To assure proper performance, the

highest point of discharge line

should be higher than 5’ off the

floor.

9. Clean any debris in the pump

reservoir if necessary.

10. Do not handle the pump until you

have disconnected it from the

power source. Follow all guidelines

for electrical safety discussed in

General Safety.

11. Do not use a pump discharge pipe

smaller than the pump discharge

size.

12. After installation, test pump to

make sure that system is working

properly.

13. Make sure that installation

conforms to all local and national

codes.

14. Local codes may require the use of a

condensate neutralizer when using

this pump.

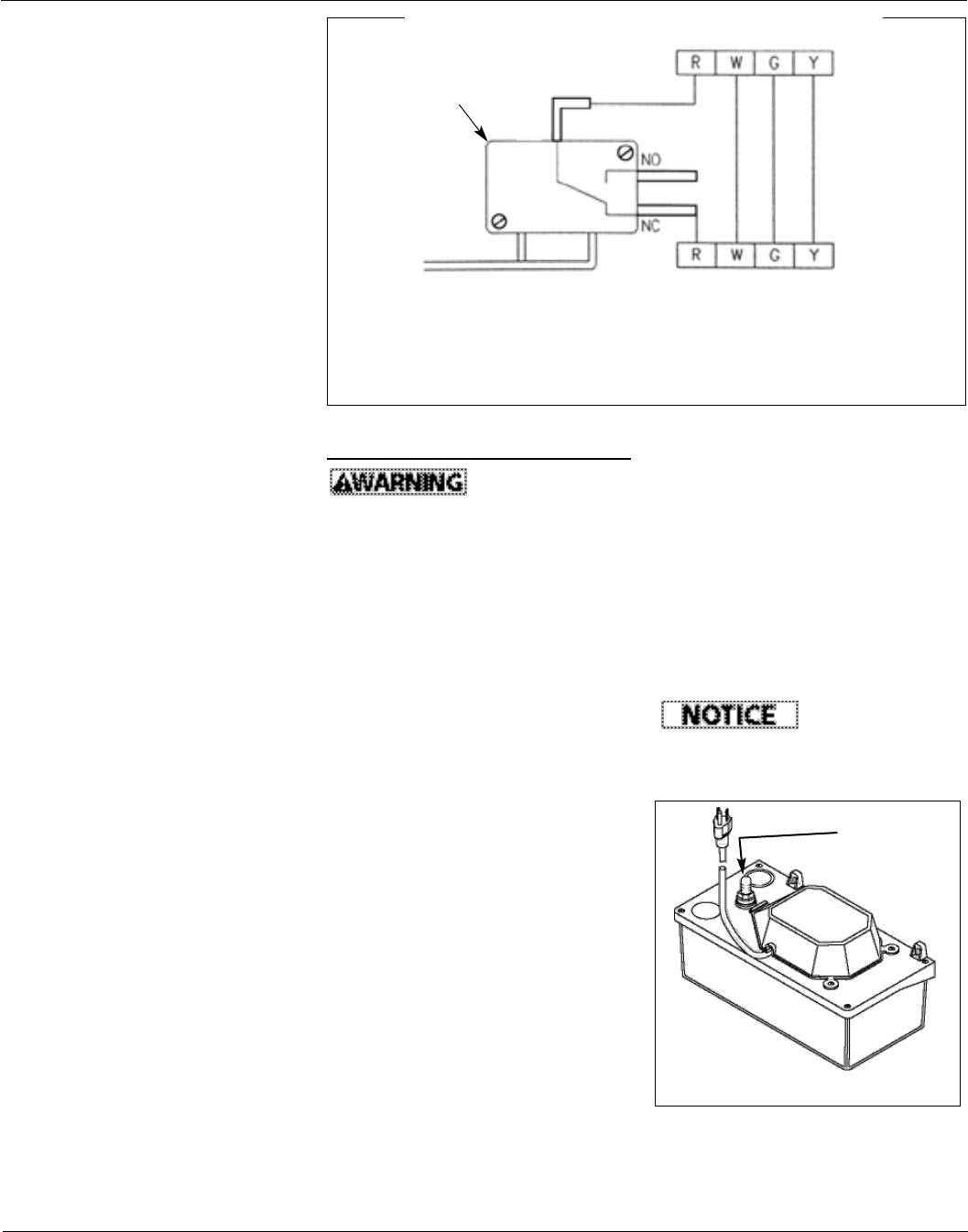

Figure 7 - Typical wiring diagram for pumps provided with safety switch

NOTE: The alarm can be wired into the safety

switch at the normally open (“NO”) contact.

Maintenance

Make certain that

the pump is

unplugged before attempting to

service or remove any component. This

pump is assembled in the factory using

special equipment; therefore only

authorized service dealers or qualified

electricians should attempt to repair

this unit. Improper repair can cause an

electrical shock hazard.

CLEANING RESERVOIR AND

IMPELLER

1. Unscrew two screws through

mounting brackets, and remove

pump from wall, if mounted.

2. Remove reservoir from deck by

unscrewing the four screws located

at the corners of the reservoir cover.

3. Remove the impeller cover by

unscrewing the five screws on the

underside of the motor. Pull out the

impeller shaft assembly.

4. Use a damp cloth to wipe off the

gasket and the motor assembly.

5. Reassemble impeller to motor. Then

reassemble reservoir to reservoir

cover.

CLEANING CHECK VALVE

1. Disconnect discharge line from

check valve (see Figure 8).

2. Remove check valve with 9/16”

wrench.

3. Visually check for obstructions or

damage.

4. If check valve is not damaged,

replace valve by hand-tightening.

Then tighten 1/2” turn with 9/16”

wrench.

Do not overtighten.

Damage to O-ring

seal may occur.

Typical Thermostat

Typical Thermostat Connections of Appliance

Overflow

Safety Switch

check valve

Figure 8 - Check valve