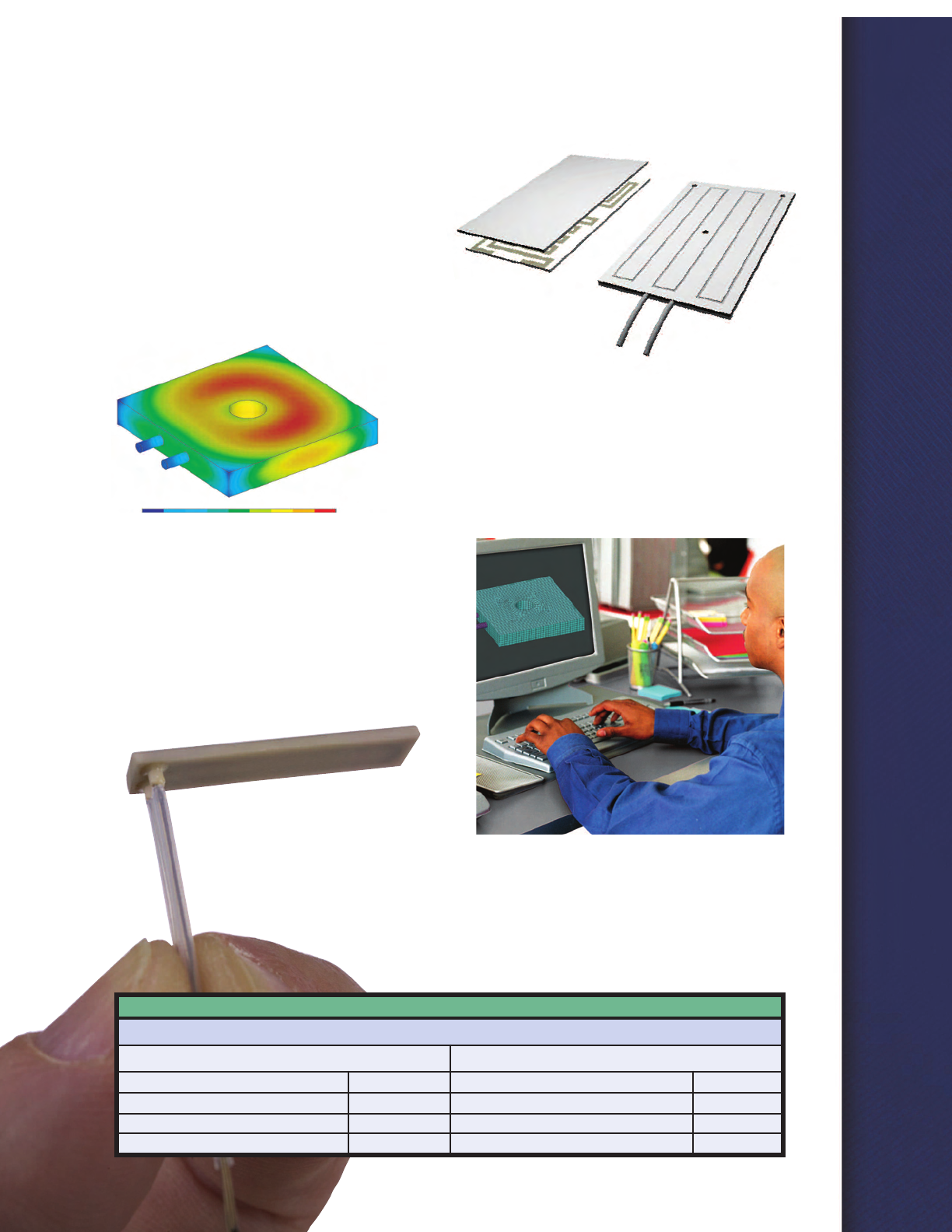

Sintered Ceramic Heater Construction

ULTRAMIC™ 600 heaters are

manufactured using a proprietary sintering

process. Sintering is a method where

aluminum nitride (AlN) ceramic powder is

heated at a high temperature, which

allows contacting particles to diffuse

together. This process creates a

monolithic, geometrically stable structure

with very low porosity.

Custom designs can be rapidly accommodated

including those with complex topographies such as

holes, notches and vacuum grooves. Using a Finite

Element Analysis (FEA) technique, the heater circuit is

optimized and the thermal performance simulated

prior to manufacture.

The high thermal conductivity of AlN

and an optimized circuit layout

combine to produce superb

temperature uniformity across the

heater surface.

Non-contaminating

AlN composition

The AlN matrix is constructed of two parts. The

heating element is printed on one of the AlN

parts. Then, the parts are sintered together,

making them one homogeneous assembly.

ULTRAMIC 600 Thermal and Physical Properties

AIN

Thermal Properties Physical Properties

Thermal Conductivity (W/mK) 140 Density (g/cm

3

) 3.26

CTE (ppm/˚C) 4.5 Hardness (Hv@500g) 1050

Surface Temperature 600˚C (1112˚F) Flexural Strength (MPa) >250

Terminal Temperature 400˚C (752˚F)

399.5

399.7

399.9

400.1

400.4

400.6

400.8

401.1

401.3

°C

401.5