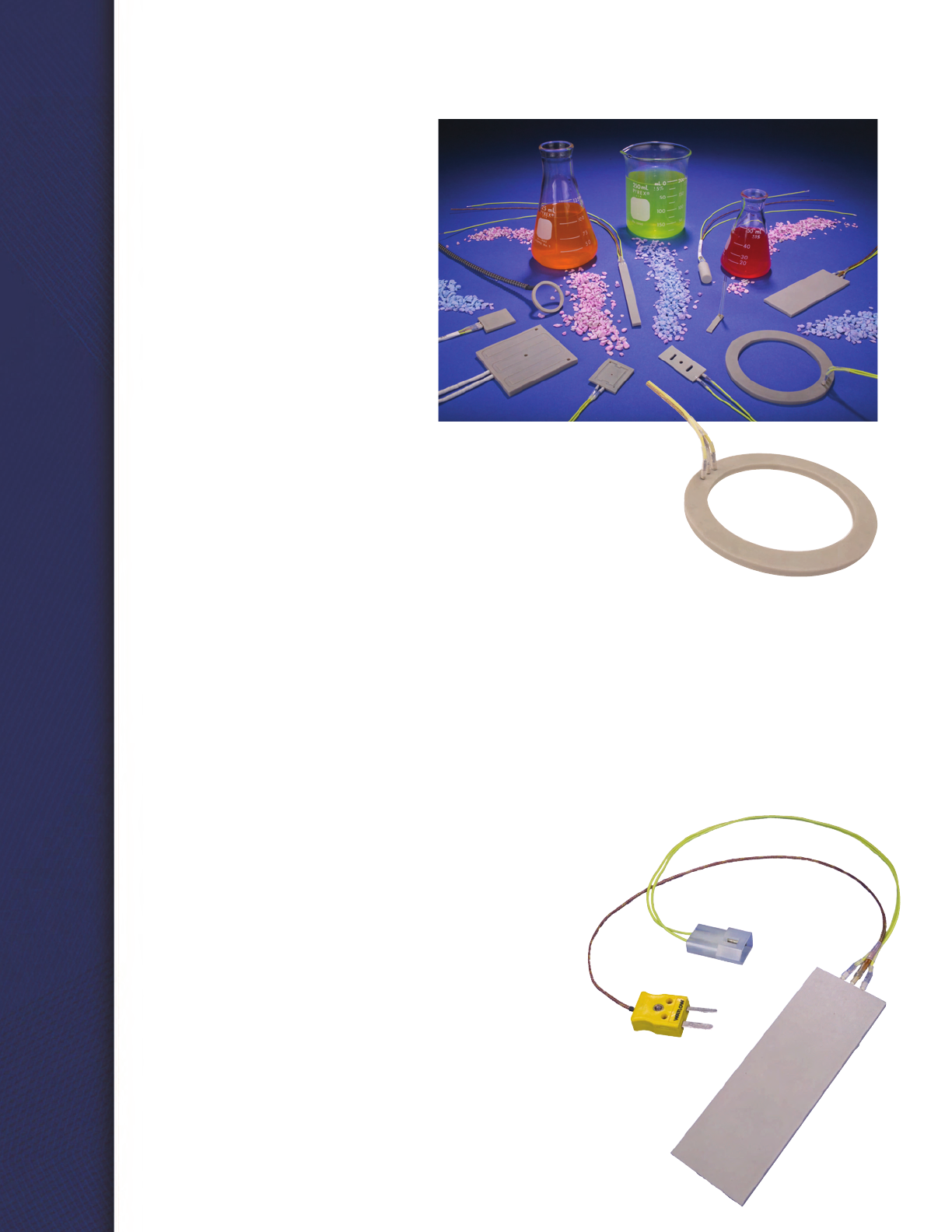

Watlow’s ULTRAMIC™ 600 heaters are

designed for thermal applications where

the high performance of an advanced

ceramic heater is required to ensure

optimal effectiveness of the equipment

and process.

ULTRAMIC 600 heaters are constructed

of aluminum nitride (AIN) and incorporate

a thermally matched proprietary heating

element that provides maximum

performance in challenging applications.

AIN is especially suitable for applications

requiring a clean,

non-contaminating heat source.

Additionally, the excellent geometric

stability ensures consistent part-to-part

thermal contact during heating cycles.

Watlow AIN heaters can operate up to 600°C with an ultra-

fast ramp rate of up to 150°C per second depending on the

application, heater design and process parameters. In

addition to excellent thermal characteristics, the ULTRAMIC

600 has high electrical isolation and typically provides

superior chemical resistance as compared to traditional

metal heaters.

Robust AlN ceramic

• Creates a homogeneous assembly for atmospheric and

vacuum applications

• Provides durable heater construction and thermal transfer

necessary for high temperature and long heater life

• Permits the design of a high watt density, fast responding,

heater in a very small package

• Geometrically stable due to low coefficient of thermal

expansion (CTE)

• Process temperatures up to 600°C (1112°F) depending on

application parameters

Rapid prototyping

• Finite Element Analysis (FEA) provides rapid ‘virtual’

prototyping of heater performance prior to the

manufacturing process

• Custom prototypes can be delivered in weeks rather than

months with innovative design and manufacturing practices

Superior electrical performance

• Low leakage current; <10 µA at 100°C

• Breakdown voltage; >2000VÎ(dc)

High thermal conductivity

• Makes for a fast temperature ramp rate of up to 150°C

(270°F) per second (depending on application parameters)

• Allows for quick cool-down

• Provides extremely uniform temperatures over the

heater surface

The Revolutionary ULTRAMIC™ 600

Thermocouple integrated into

assembly (patent pending)

• Bonded assembly process ensures

reliability of heater/sensor interface

• Optimized temperature sensing improves

accuracy

• High response rate in ramping applications

UL

®

agency compliance (pending)

• Designed to meet global safety standards

Ramp rates to

150°C per second

UL

®

is a registered trademark of Underwriter’s Laboratories, Inc.