ANTIFREEZE

1. Antifreeze added to boilers must be non-toxic, and must be

of a type. specifically intended for use in closed hydronic

heating systems. Under no circumstances should

automotive antifreeze be used.

2. Use of antifreeze in any boiler may reduce capacity by 10%

or more and increase fuel consumption. Tankless coil

performance will fall as concentration of antifreeze is

increased.

3. Because antifreeze forms slush rather than hard ice, it is

safe to protect only to 10 degrees above coldest temperature

anticipated provided slush formed can move towards

expansion tank.

26

MODEL NO.

VOLUME

IN GALLONS

MODEL NO.

VOLUME

IN GALLONS

DPF3 7 DPF3T 10

DPF4 9 DPF4T 12

DPF5 11 DPF5T 14

DPF7 15 DPF6T 16

DPF9 19 DPF8T 20

DPF7TT 21

WATER VOLUMES OF PF SERIES BOILERS

PIPE SIZE PIPE MATERIAL FACTOR

½" Copper 82.5

½" Steel 63.5

¾" Copper 40.0

¾" Steel 36.0

1" Copper 23.3

1" Steel 22.2

1¼" Copper 15.3

1¼" Steel 12.8

1½" Copper 10.8

1½"Steel9.5

2" Copper 6.2

2" Steel 5.8

PIPING VOLUMES

Divide total length of piping in feet by Factor A below to

determine water volume in gallons.

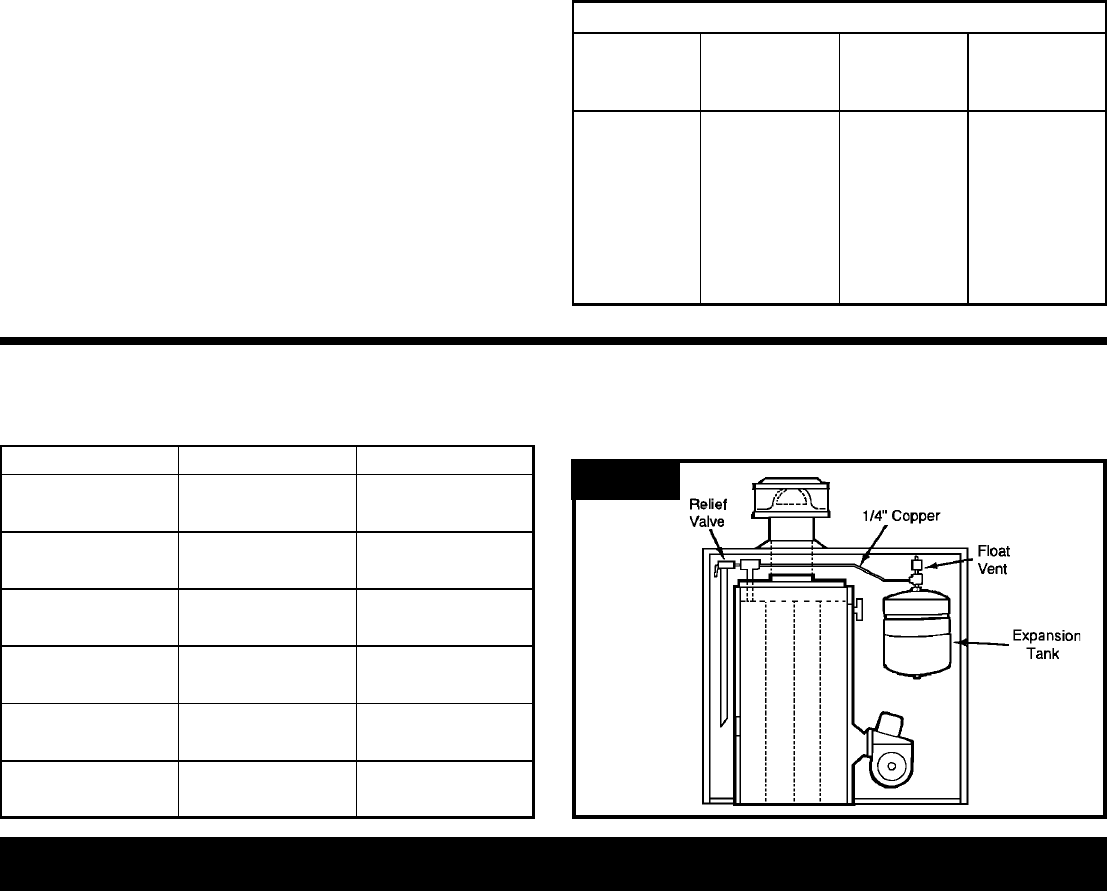

ALTERNATE AIR ELIMINATION METHOD

As boiler temperature increases, air will move from top of boiler

toward float vent even if lower. As boiler temperature

decreases, water will move from expansion tank toward boiler.

FIG. 23

Oil Burner and Controls Start-Up and Adjustment

WEATHERPROOF BOILERS

This boiler was designed to produce the ultimate in useable

heat from a gallon of fuel oil. To adjust the air-fuel mixture by

eye is to waste fuel unnecessarily and to create undesirable

soot.

Repeat - Do not adjust air by eye. Any time air adjustment or

oil rate is changed, combustion must be checked with

instruments. With chamber fully warmed up, find highest C02

level at which zero smoke can be maintained. Then add extra

air until C02 falls off about 1%. Final setting should be at least

11% C02. If unable to obtain that reading, check for internal oil

leaks, incorrect flame retention head or faulty or incorrect

nozzle. Draft will vary as air is adjusted. It should be left at as

near zero as possible at breeching.

The correct nozzle is the smallest which will do the job properly.

Long continuous runs with minimum starts and stops conserve

the most energy. The nozzle which provides the highest C02

with the least smoke for a particular application is always

recommended.

Warning: A firing rate that is too low can result in a

condensation problem within the chimney and boiler causing

severe rust and corrosion. When domestic water is being

heated, by-pass piping is recommended only when an Indirect

Water Heater is used as shown on Figure 20. If no domestic

water heating is involved, by-pass piping is always

recommended as shown on Figure 21.

Beckett AFG or CF375 Oil Burner

A Beckett model AFG oil burner is used to fire boilers at 2.00

gph or less. At firing rates above 2.00 gph, a Beckett model

CF375 is required. A model AFG burner shipped with your EV

Series boiler is equipped with an F3 flame retention head, the

size most commonly used. It is possible the head must be

changed to match the nozzle firing rate required, and it is

recommended the installer carry a complete assortment of

Beckett flame retention heads. When head ratings overlap, a

smaller head with air shutter fairly well open will generally

provide better combustion than a larger head with air shutter

near closed. See head size selection chart below. For firing

rates under 1.00 gph