With all high efficiency boilers, care must be taken to minimize

condensation. Therefore, cold standby is not

recommended and may be used only with a piping, bypass

as shown on Figure 12. This requires a change in control

wiring. Please contact factory prior to making that change.

When cold standby is not utilized, the homeowner might

possibly object to the burner starting when space heat is not

required. To avoid this, an optional outside thermostat may

be used to shut down the system totally when outside

temperature is above a specific limit set by the homeowner.

When outside thermostat is not used, Jumper T-T Terminals

on relay.

L8151 CONTROL SETTINGS

Use the following setting for the first adjustment:

17

High Limit Set Point .............. 180°F

Low Limit Set Point ............... 160°F

Differential............................... 20°F

These settings may be altered based on the heating system

response. During very cold weather if the heating system does

not provide quite enough heat, the high limit control setting

may be raised to a maximum of 200°F. If more domestic hot

water is required, the low limit control setting may also be

raised to a maximum of 180°F. Whenever adjusting either the

high or low limit the high limit control setting must be set at

least 20°F above the low limit. The differential control setting

is typically 20°F but may be adjusted to vary the time it takes

the burner to respond to a call for domestic hot water.

Oil Burner and Controls Start-Up and Adjustment

INDOOR DIRECT EXHAUST BOILERS

Instruction manual enclosed in burner carton must

be followed in regard to start-up and adjustment

1. A Beckett model AFG post-purge oil burner is normally

supplied with boilers to be fired at 2.00 gph or less. It is

equipped with an F3 flame retention head, the size most

commonly used. It is possible the head must be

changed to match the nozzle firing rate required, and

it is recommended the installer carry a complete

assortment of Beckett flame retention heads. When head

ratings overlap, a smaller head with air shutter fairly well

open will generally provide better combustion than a larger

head with air shutter near closed.

SEE HEAD SIZE SELECTION CHART ON PAGE 16.

SUGGESTED NOZZLES, HEADS, AND PRELIMINARY

SETTINGS FOR VARIOUS FIRING RATES ARE

SHOWN ON PAGE 40.

2. At firing rates above 2.00 gph, a special Beckett model

CF375 burner must be used and is supplied if specified

by purchaser.

3. Post-purge oil burners are supplied with pump pressure

set at 140 psi. Nozzle output will be approximately 18%

greater than that at 100 psi.

4. The burner is not supplied with a nozzle. The correct

nozzle is the smallest which will do the job properly. Long

continuous runs with minimum starts and stops conserve

the most energy. The nozzle which provides the highest

C02 with the least smoke for a particular application is

always recommended.

5. WARNING: Too low a firing rate can cause excessive

condensation within the boiler and flue resulting in severe

rust and corrosion. A piping by-pass is recommended to

minimize this problem. See Figure 12.

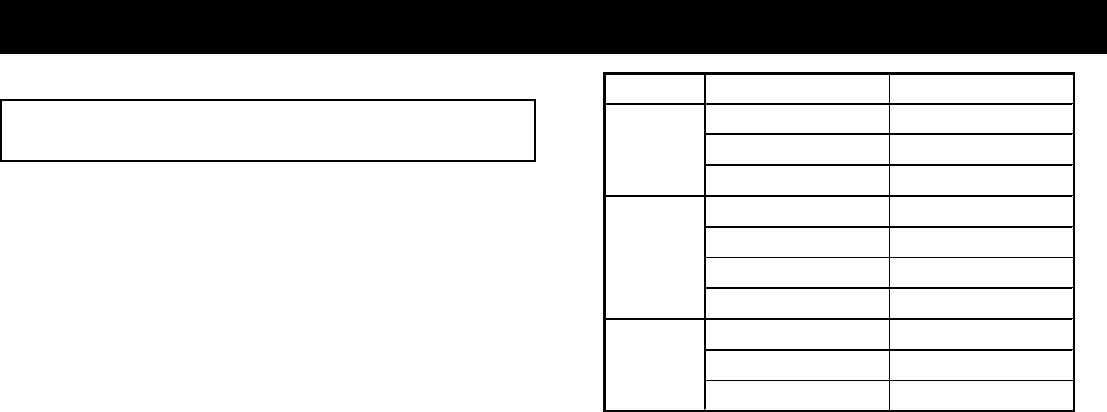

6. If Beckett AFG burner is to be fired at less than 1.00 gph,

it is possible that a low firing rate baffle will be required.

For firing rates not specified on page 40, see chart below

on which an x indicates that a baffle is necessary. See

also instruction sheet with baffle in burner carton.

HEAD FIRING RATE, GPH LOW FIRE BAFFLE

.50 X

.65 X

.75 —

.75 X

.85 X

.90 —

1.00 —

.85 X

.90 X

1.00 —

F0

F3

F6

7. Using three acorn nuts, studs and washers from hardware

package, fasten burner to mounting plate. Do not disturb

chamber when inserting firing head.

8. Mount L8151 control on boiler jacket above and to the

right of burner using sheet metal screws in holes located

in jacket. Wiring harness is provided. When well is used

at the rear of a larger boiler, it might be necessary to

relocate the control with longer wiring not provided.

9. If boiler has a tankless coil, insert well for the L8151 remote

bulb in coil plate. Run capillary tube through sight glass

opening in jacket.

10. If a tankless coil is not used, install 3/4" well and bulb with

a bushing either in the 1 1/2 supply opening opposite the

one used to feed radiation, or in a reducing tee in the 1 1/2

supply opening that feeds radiation.

11. Mount overfire pressure switch at upper right of burner

on screws already in jacket. Connect by 1/4" copper tube

to brass tee at upper left of burner.

Burner will shut down if overfire pressure reaches .17"

H2O due to a plugged flue or high wind. If high wind

causes nuisance shutdowns, mount switch on an angle

bracket with diaphragm horizontal. Shutdown will then

occur at .25" H2O.