R

Accessories

WSHP-PRC003-EN

183

Pump Module

The pump module and hose kit make a

complete self-contained pumping pack-

age for distributed pumping systems.

These kits contain all the necessary

components for the installation, opera-

tion and maintenance of the water cir-

cuit of a closed loop geothermal appli-

cation. Standard pump module features

include insulated Grundfos pumps,

insulated cabinet, bronze or cast iron

pump, and 3-way brass valves. The

module is factory piped, wired and

mounted. See Figure 40 for pump mod-

ule assembly. Literature number

WSHPC-IN-5 (72-9006-03) will provide

electrical and dimensional require-

ments for the PMCA and PMBA prod-

ucts.

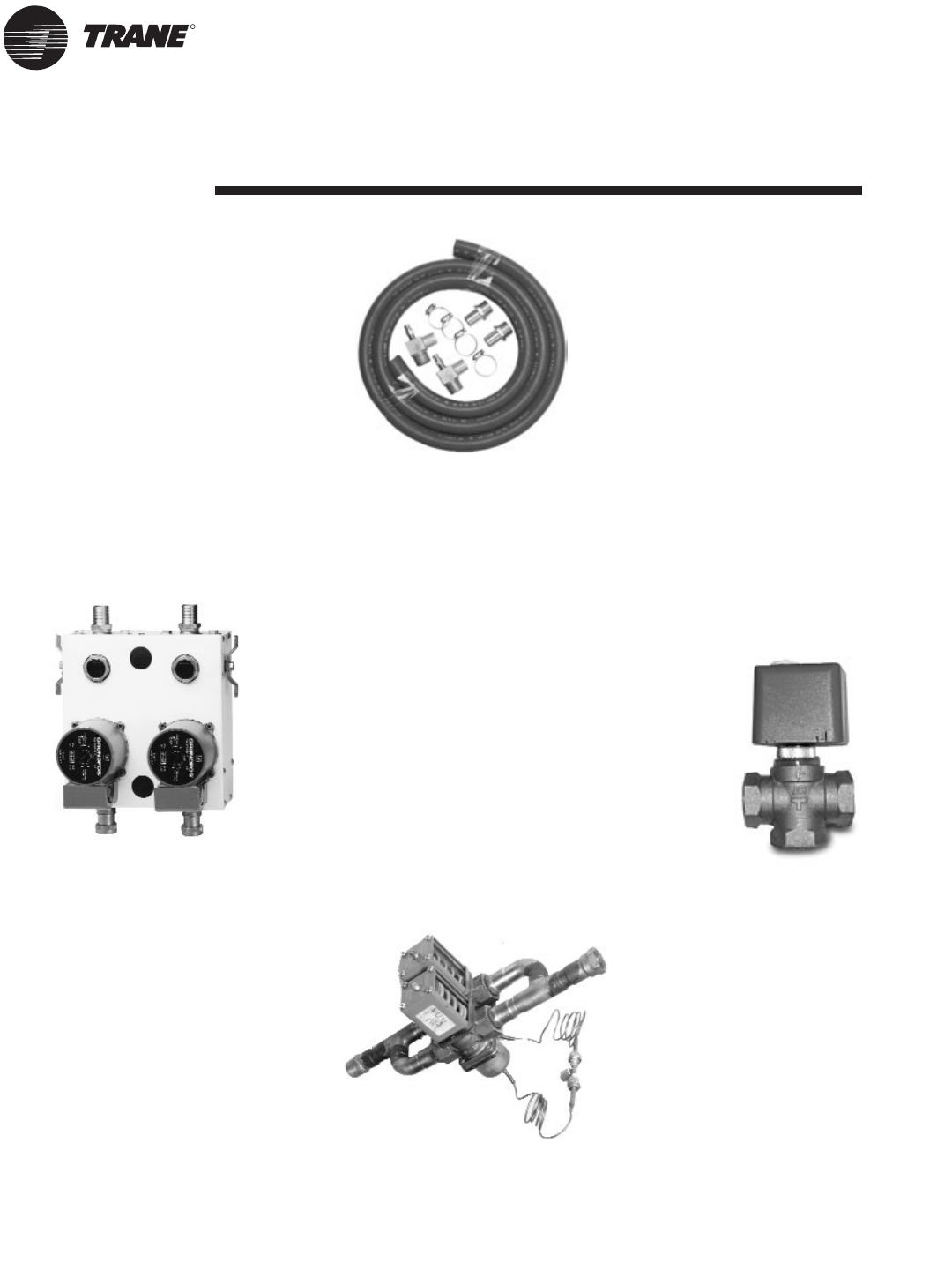

Figure 37: Pump module

Pump Module Hose Kit

The pump module hose kit consists of

two brass, 3/4 or 1-inch male pipe

thread (MPT) -by-barb fittings; two

brass 90 degree 1-inch, MPT-by-barb

elbows with pressure/temperature

ports; and 10 feet of rubber hose with 4

hose clamps. The pump module hose

kit is available separately from the

pump module.

Figure 38: Pump module hose kit

Water Regulating Valve

Assembly

The water regulating valve assembly

consists of a direct acting valve and a

reverse acting valve installed on the

water-out side of the unit. The valve

connection sizes shall range from 1/2"

to 1 1/2" FPT. The direct acting valve

opens in response to an increase in dis-

charge pressure during the cooling

cycle. The reverse acting valve opens in

response to a decrease in suction pres-

sure during the heating cycle. Water

regulating valves should be used where

low flow and low or high fluid tempera-

ture conditions could occur. See page

29 of this manual for application infor-

mation.This option is beneficial with

open loop systems, but not necessary.

Figure 39: Water regulating valve

Motorized Water Valve

The motorized water valve is installed

on the return line of the water loop sys-

tem between the loop and the loop’s

pump module. This isolation device is

less expensive and a very effective

alternative to the water regulating

valve.

When the compressor begins running,

the valve will open, allowing water to

flow through the unit. As the compres-

sor shuts down, the valve slowly closes

off. The main purpose of the motorized

valve is to shut-off the flow of water

through the unit when the unit is off,

thus reducing water consumption. The

motorized valve is fast opening to pre-

vent compressor trip-out, and slow

closing to prevent water hammer.

Figure 40: Motorized water valve