28 PKG-SVX14A-EN

control disarming rearming

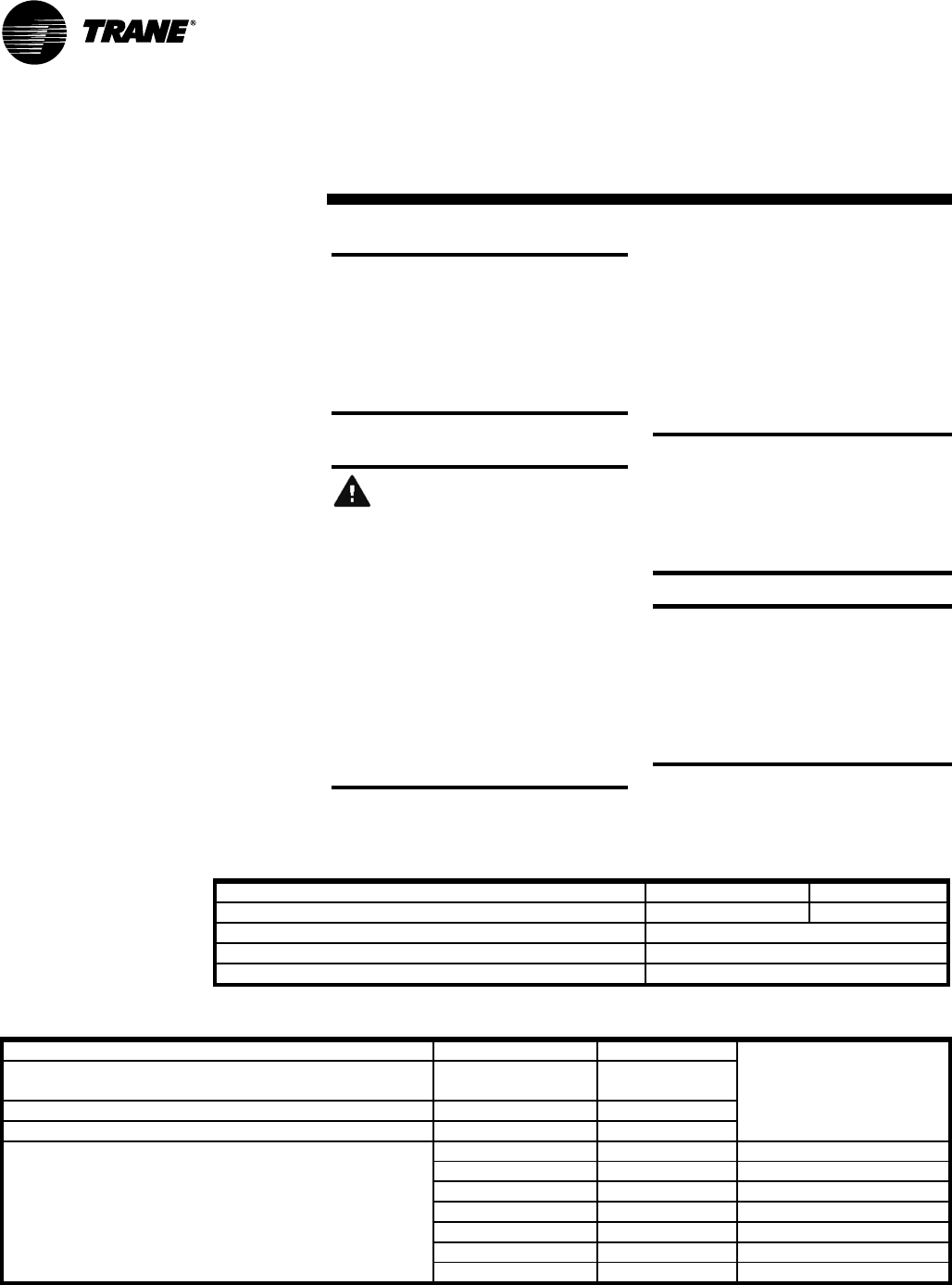

high pressure control (air-cooled & 12-ton water cooled) 624±17.5 psig 464±29 psig

high pressure control (water-cooled except 12-ton)

450±10 psig 348±14.5 psig

low pressure contol 51±7 psig 94±7 psig

266±5F 194±5 3 / 204-230 & 575

275±5F 198 5 / 208-230

266±5F 198 5 / 575

194±5 F 135 7.5 - 10 / 208-230

248±5F 156 7.5 - 10 / 575

194±5F 135 12 - 15 / 208-230

221±5F 142 12 - 15 / 575

motor windings thermostat, standard motor only

unit (ton / voltage)

Maintenance

maintenance

procedures

water-cooled air-cooled

high pressure 280 to 430 psig 320 to 570 psig

low pressure

superheat

subcooling

100 to 160 psig

4 to 9°F

5 to 10°F

Table M-MP-2. Controls adjustment

Table M-MP-1. Normal operation condition

CAUTION

Motor Winding Damage!

Do not use a megohm meter or apply

greater than 50 VDC to a compressor

motor winding while it is under a

deep vacuum. Voltage sparkover may

cause damage to the motor windings.

WARNING

Hazardous Pressures!

If a heat source is required to raise

the tank pressure during removal of

refrigerant from cylinders, use only

warm water or heat blankets to raise

the tank temperature. Do not exceed

a temperature of 150°F. Do not, under

any circumstances, apply direct flame

to any portion of the cylinder. Failure

to follow these safety precautions

could result in a violent explosion,

which could result in death or serious

injury.

Charging the Refrigerant System

To completely charge the system, charge

gaseous refrigerant into the suction line

shrader valve with the unit running.

However, make sure that some

refrigerant is present in each circuit

before starting the compressors.

CAUTION

Compressor Damage!

Do not allow liquid refrigerant to enter

the suction line. Excessive liquid

accumulation in the liquid lines may

result in compressor damage.

CAUTION

Compressor Damage!

Never manually or automatically

pump down below 7 psig. This may

cause the compressor to operate in a

vacuum and result in compresor

damage.