All installations and services must be performed by qualified service personnel.

26

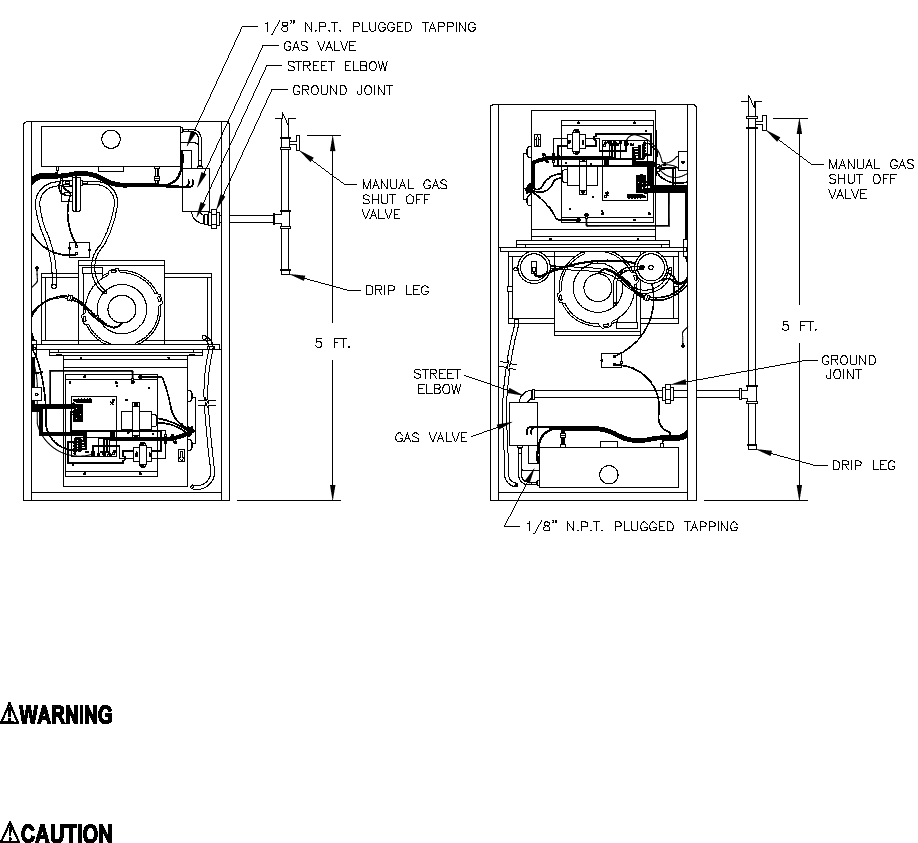

Figure 18

2. A drip leg must be used on both LP and natural gas installations prior to the furnace in order to trap oil,

condensate and other impurities which might otherwise lodge in the gas valve or plug the burner orifice. A drip

leg shall be provided at the outlet of the gas meter when there is excessive condensation between the gas meter

and the furnace. Failure to install a drip leg may void the limited warranty on the furnace.

: All gas piping must be leak tested using a soap and water solution (when the gas is turned on)

following the procedure outlined in Section III, J, of this manual. A final test for gas leakage must be made after

purging the gas line (refer to Section IV, B, of this manual). This test must be conducted with the unit operating

and should include the furnace piping and gas valve. Never use an open flame to check for a gas leak.

: Care must be taken not to wet electronic components during leak test. Wetting the primary

ignition module may damage its circuitry and cause a hazardous situation. Dry moisture from all leads and

terminals if wetting occurs. Wait at least 24 hours for the circuit to fully dry before energizing the burner circuit.

J1. REQUIREMENTS AND SIZING OF DUCT WORK

The duct system must be sized and installed by a qualified installer or service person, following the design standards

of the Air Conditioning Contractors of America (ACCA) or ASHRAE.

1. When it is located in the same room as the furnace, a return air register must be installed a minimum of 20 feet

away from the furnace.

2. The return air duct shall also be sealed to the furnace and also terminate outside of the furnace space, if supply

ducts carry circulated air to areas outside the space containing the furnace.

3. The return air duct system must equal the supply air duct system in its capabilities. Use a supplier's catalog for

proper sizing of outlet and return air registers and grills to ensure that they meet the CFM requirements of the run to

which they are connected.