NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

5

Install only a ¹⁄₂" (1 ¹⁄₂" max.) inside diameter

approved gas line through the firebox wall for

connection to the unvented room heater inside

the firebox.

Ensure that a sediment trap is installed in the

existing gas line, if not, install a sediment trap

upstream of the heater to prevent moisture and

contaminants from passing through trap to the

heater controls and burners. Failure to do so

could prevent the heater from operating reli-

ably.

An external regulator must be used on all pro-

pane (L.P.G.) heaters, in addition to the regula-

tor fitted to the heater, to reduce the supply tank

pressure to 13" w.c. (maximum). Any copper

tubing used to supply propane (L.P.G.) from

the tank must be internally tinned.

IMPORTANT: HOLD HEATER REGULATOR

WITH A WRENCH TO PREVENT MOVEMENT

WHEN CONNECTING TO INLET PIPING.

Check Gas Type: The gas supply must be the

same as stated on the heater’s rating plate. If

the gas supply is different, DO NOT INSTALL

the heater. Contact your dealer for the correct

model.

WARNING: CONNECTING DIRECTLY TO

AN UNREGULATED PROPANE (L.P.G.)

TANK CAN CAUSE AN EXPLOSION.

IMPORTANT: RE-PACK INSULATION MATE-

RIAL IN SQUARE HOLE AROUND GAS LINE,

INTERIOR AND EXTERIOR, TO SEAL.

Consult installation and operating instructions

for the model of unvented room heater to be

installed.

Checking Gas Connections: Test all gas joints

from the gas meter to the gas heater regulator

for leaks using soap and water solution after

completing connection. DO NOT USE AN OPEN

FLAME.

WARNING: THE CANOPY HOOD MUST

BE IN PLACE TO BE IN COMPLIANCE

WITH THE CLEARANCES SPECIFIED IN

FIGURE 3

. DO NOT REMOVE OR RE-

PLACE CANOPY, ONLY USE CANOPY

SUPPLIED WITH THE FIREBOX. DO

NOT USE ANY CANOPY WHICH MAY BE

PROVIDED WITH THE DECORATIVE TYPE

UNVENTED ROOM HEATER.

If your mantel profile is unsafe, you may either:

• Raise the mantel to an acceptable height, or

• Remove the mantel.

Floor clearance: These fireplaces may sit

directly on a combustible surface.

ASSEMBLY STEPS

Note: Illustrations shown in this manual re-

flect “typical” installations with nominal di-

mensions and are for design and framing

reference only. Actual installations may vary

due to individual design preferences. How-

ever, always maintain minimum clearances to

combustible materials and do not violate any

specific installation requirements. Refer to the

Framing Specifications Figures on page 8.

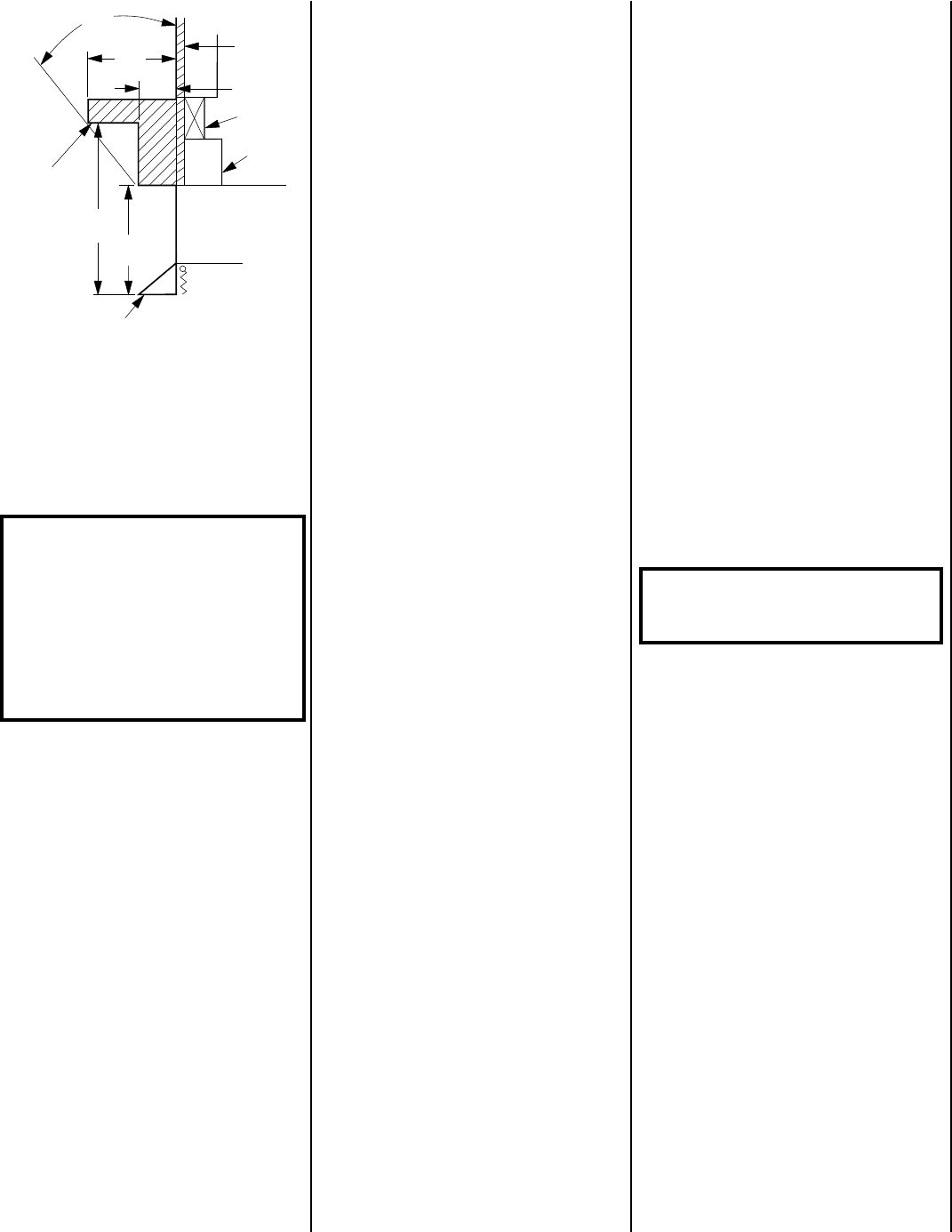

Figure 3

Noncombustible material (minimum re-

quirements) with wood mantel or other

combustible projections: To install the fire-

box with a wood mantel, shelf or other com-

bustible projection above firebox opening.

Refer to

Figure 3

.

Note: The following steps represent the nor-

mal sequence of installation. Each installation

is unique, however, and might require a differ-

ent sequence.

Step 1. Position firebox prior to framing or

into prepared framing.

Step 2. Field wire main power supply to circu-

lating models for fan kit. (Electrical connec-

tions should only be performed by an experi-

enced, licensed/certified tradesman.)

Step 3. Plumb gas line. (Gas connections

should only be performed by an experienced,

licensed/certified tradesman.)

Step 4. Install decorative type unvented room

heater per the instructions provided with the

unvented room heater.

Step 5. Complete finish wall material, sur-

round and optional hearth extension to your

individual taste.

INSTALLATION

Gas Line Installation

CAUTION: PLUMBING CONNECTIONS SHOULD

ONLY BE PERFORMED BY A QUALIFIED, LI-

CENSED PLUMBER. MAIN GAS SUPPLY MUST

BE OFF WHEN PLUMBING GAS LINE TO FIRE-

PLACE OR PERFORMING SERVICE.

Consult all local codes.

It is recommended that the ¹⁄₂" gas line enter

the side of the firebox. Connect the gas line

before the firebox is enclosed in the finished

wall. The gas knockout is determined by an

indentation located at the bottom and slightly

off center in the side refractories. THE KNOCK-

OUT IS ALWAYS REMOVED FROM INSIDE

THE FIREBOX. If removal is attempted from

the outer wrapper, side-refractory damage

may occur. With a medium-sized hammer,

lightly tap the surface of the indentation. The

refractory material is very thin in this area and

is easily removed. Once a small hole has been

made, continue tapping until you have reached

sufficient diameter for the gas line to fit

through. The entire knockout does not have

to be removed.

18"

Min.

9"

Min.

Fireplace

Opening

Spacer

Combustible

Mantel

and Trim

8"

Max.

3"

Finished

Wall

Header

Canopy

Safe

Zone