Large Dehumidifying Dryers Maintenance 42

6-2 Preventative Maintenance

Cleaning or Replacing the Process Air Filters

Regular filter cleaning will keep your dryer operating at peak efficiency. The process air

filters protect the centrifugal blowers from plastic fines being drawn in from the drying

hopper. Filters should be cleaned when airflow restriction trips the dirty filter alarm. Filters

should be replaced at least once a year.

Caution! Operating the dryer without the process air filters installed will void the

warranty.

On 600-1500 cfm dryers, there is a single high-temperature (up to 350ºF) filter mounted

above the process blower on the rear of the dryer. On 2000-3000 cfm dryers, there are two

high-temperature (up to 350ºF) filters located in the housing under the blower platform on the

left rear corner of the dryer.

Vacuuming. Vacuum cleaning is the preferred method for cleaning the process air filters

because compressed air or high-pressure washing can damage the filter. Vacuuming removes

most large particles and surface contaminant. Use a commercial duty vacuum cleaner and

vacuum the filter from the air intake (dirty) side only.

Compressed Air Cleaning. Blow clean, dry compressed air up and down the pleats, blowing

out the filter from the clean side. Do not shoot the air in a criss-cross motion against the grain

of the pleats—this won’t clean the filter, and it may damage it. Compressed air should be less

than 100 psi—use a 1/8 diameter nozzle at least 2 inches away from the filter.

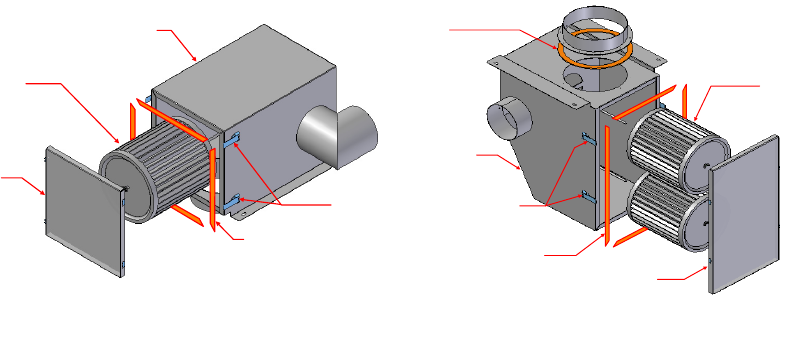

Figure 16: Process Filter Housing

High

Temeprature

Gasket

Stainless Steel

Filter Housing

High

Temperature

Cartridge Filter

Stainless Steel

Filter Housing

Cover

Filter Housing

Cover Latches

Filter Housing

Cover Latches

High

Temeprature

Gasket

Stainless Steel

Filter Housing

Cover

High

Temperature

Cartridge Filter

High

Temeprature

Gasket

Stainless Steel

Filter Housing

600-1500 cfm dryers 2000-3000 cfm dryers