Large Dehumidifying Dryers Functional Description 14

Regeneration

Filter

Regeneration

Blower

Process

Blower

Regeneration

Exhaust

Process

Heater

Process

Filter

Insulated

Drying

Hopper

Right Desiccant

Regeneration

Heaters

Dryer Valve

Left Desiccant

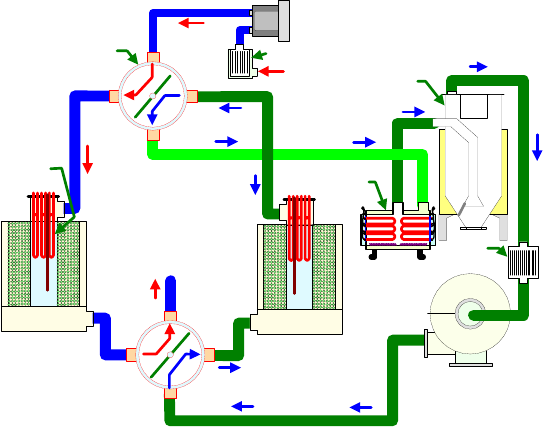

AD600-AD1500

Dryer Flow Schematic

Left Desiccant in

Regeneration

Sequence of Operation

When the dryer is started, the main air valve rotates 360º and then moves to place the last

successfully regenerated desiccant bed online. If the dryer was powered off using the main

power disconnect or E-stopped, then the regenerating bed is placed back into regeneration,

and the regeneration cycle is started over. The main air valve is allowed a period of time to

move from one position to the other. If the main air valve does not complete positioning

within the allotted time, then a “Main Air Valve Fail” alarm is generated and the dryer stops

the process air blower and disables the drying hoppers and regeneration circuit.

If the closed loop regeneration option is enabled, the regeneration closed loop valve moves to

the open loop position. The system always begins the cooling phase for a regeneration cycle

using ambient (open loop) air. The closed loop regeneration valve is allowed a period of time

to move from the closed to the open loop position and a “Closed Loop Valve” alarm is

generated if the valve fails to reach the commanded position within this time. This alarm will

disable the regeneration circuit but does not stop the process air system or drying hoppers.

Once the main air valve and closed loop regeneration valve are in place, the process air

blower starts. The system monitors the process air blower’s overload, starter auxiliary contact

feedback and air pressure. Loss of any of these items when the process air blower is running

will cause the process air blower and the drying hopper’s process heaters to shut down.

The process air heaters will turn on after a delay to allow the process air blower to accelerate

the operating speed.

During normal operation, one set of desiccant beds is connected to the process air circuit

while the other set is being regenerated. When the offline beds are done regenerating, they

will be switched into the process air circuit and the other beds will be regenerated. The

default bed switch setting is based on time. If the Dewpoint Switch option is enabled, the

beds will switch when the process air dewpoint reaches the dewpoint switch point. The

dewpoint option will automatically disable itself and an alarm will be generated if the

dewpoint sensor or related electronics fail.