GS110 DIRECT VENT BOILER INSTALLATION AND OPERATION INSTRUCTIONS Page 11

Horizontal vent systems shall terminate at least 4 feet

(1.3 m) below, 4 feet (1.3 m) horizontally from or 1 foot

(0.23 m) above any door, window or gravity air inlet into

any building. It must not terminate less than 4 feet (1.3

m) horizontally from, and in no case above or below,

unless a 4 feet (1.3 m) horizontal distance is maintained,

from electric meters, gas meters, regulators and relief

equipment and not less than 7 feet (2.3 m) from any

adjacent public walkway. The bottom of the vent

terminal(s) shall be located at least 5 feet (1.5 m) above

the air intake terminal(s). Avoid terminal locations likely

to be affected by winds, snowdrifts, people and pets.

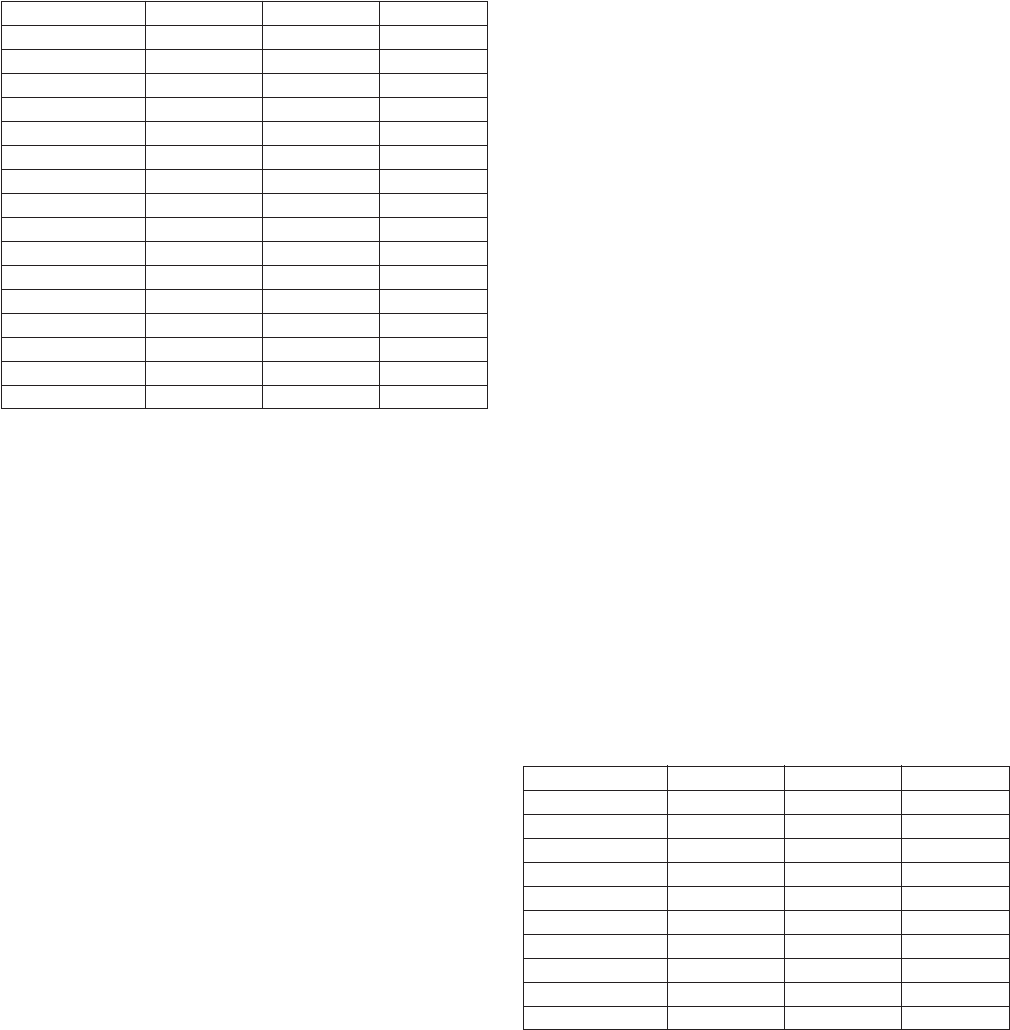

Table 4 - Certified Vent & Intake Terminals

VERTICAL DIRECT VENT SYSTEMS

See Figures 6 & 10. The vent materials used in vertical

positive pressure vent systems must be certified to UL

1738 for installations in the United States, ULS636 for

installations in Canada.

The maximum length for the vertical vent system is

listed in Table 4. Each 90° elbow is equal to 5 linear

feet (1.5 m) of pipe. To maximize the performance of

single wall sheet metal vent systems locate 90° elbows

as far from the boiler as possible and from one another.

If any part of a single wall metal vent system passes

through an unheated space it must be insulated with

insulation rated for 400°F. Structural penetrations must

be made using approved fire-stops.

The vent system must be both gas tight and watertight.

All seams and joints in metal pipes must be joined and

sealed in accordance with the vent system

manufacturer’s instructions.

Vertical vent systems must be terminated with an

approved terminal cap as shown in Figures 6 & 10.

HORIZONTAL VENT

POSITIVE PRESSURE SYSTEMS

See Figure 3. The vent materials used in horizontal

positive pressure vent systems must be certified to UL

1738 for installations in the United States, ULS636 for

installations in Canada.

The maximum vent lengths are listed in Table 3.

Each 90° elbow is equal to 5 linear feet (1.5 m) of pipe.

To maximize the performance of single wall sheet metal

vent systems locate 90° elbows as far from the boiler

as possible and from one another. Horizontal vent

systems should be as short and straight as possible.

When horizontal vent runs exceed 5 feet (1.5 m) they

must be supported at 3 foot (0.98 m) intervals with

overhead hangers. The vent system must be pitched

down, toward the vent terminal, 1/4" per foot (21 mm

per meter). If any part of a single wall metal vent system

passes through an unheated space it must be insulated

with insulation rated for 400°F. Structural penetrations

must be made using approved thimbles.

The vent system must be both gas tight and watertight.

All seams and joints in metal pipes must be joined and

sealed in accordance with the vent system

manufacturer's instructions.

Horizontal vent systems shall terminate at least 4 feet

(1.3 m) below, 4 feet (1.3 m) horizontally from or 1 foot

(0.23 m) above any door, window or gravity air inlet into

any building. It must not terminate less than 4 feet (1.3

m) horizontally from, and in no case above or below,

unless a 4 feet (1.3 m) horizontal distance is maintained,

from electric meters, gas meters, regulators and relief

equipment and not less than 7 feet (2.3 m) from any

adjacent public walkway. The bottom of the vent

terminal(s) shall be located at least 5 feet (1.5 m) above

the air intake terminal(s). Avoid terminal locations likely

to be affected by winds, snowdrifts, people and pets.

Protect building materials and vegetation from

degradation caused by flue gasses.

Table 5- Certified Vent Terminals

Dia. (in.)

3

4

3

4

3

4

3

4

3

4

3

4

3

4

Part No.

300311

300312

300186

300187

300130

300131

300160

300161

7390GC

7490GC

7390TEE

7490TEE

7392GC

7492GC

7314TERM

7414TERM

Company

Protech

Protech

Protech

Protech

Protech

Protech

Protech

Protech

Heat-Fab

Heat-Fab

Heat-Fab

Heat-Fab

Heat-Fab

Heat-Fab

Heat-Fab

Heat-Fab

Description

Te e

Te e

Bird Screen

Bird Screen

45° Elbow

45° Elbow

90° Elbow

90° Elbow

Mitered

Mitered

Te e

Te e

Screen

Screen

90° Elbow

90° Elbow

Dia. (in.)

3

4

3

4

3

4

3

4

3

4

Part No.

300311

300312

300130

300131

300160

300161

7390TEE

7490TEE

7314TERM

7414TERM

Company

Protech

Protech

Protech

Protech

Protech

Protech

Heat-Fab

Heat-Fab

Heat-Fab

Heat-Fab

Description

Te e

Te e

45° Elbow

45° Elbow

90° Elbow

90° Elbow

Tee

Tee

90° Elbow

90° Elbow