I

NTREPID

21

I. EXTENDED SHUTDOWN, CLEANING OR REMOVAL OF BOILER

FROM SERVICE.

DANGER: Use CAUTION when handling chemicals and draining hot

water from a boiler. Scalding water and/or chemicals can cause per-

manent injury to the skin, eyes and respiratory system.

A. Shut down burner by disconnecting all electrical power to the

burner by turning OFF the BURNER EMERGENCY SWITCH of

this boiler. After shutting down burner, while the boiler is still hot

(180°F to 200°F), drain water from the bottom of the boiler until it

runs clear.

B. Provide corrosion protection conditioning to the boiler water in the

heating system.There are a number of commercial heating sys-

tem preparations available from your distributor. Follow the prepa-

ration manufacturer’s instructions.

1. For steam boilers, maintain a sodium chromate solution

strength of 16 oz. per 50 gallons of water; and refill to the top

of the gauge glass.

2. For water boilers, maintain a sodium chromate solution

strength of 6 oz. per 50 gallons of water, and refill to normal

fill-pressure with system vented.

3. Raise water temperature to at least 180°F. for one hour to

release dissolved gases.

4. Shut down burner by disconnecting the main switch.

C. To clean the fireside boiler surfaces, first shut down burner by dis-

connecting all electrical power to the burner by turning OFF the

OIL BURNER EMERGENCY SWITCH of this boiler in order to

perform the following work in (1) through (10) below.

1. Remove the flue pipe from the boiler flue collar and clean

thoroughly.

2. Inspect the entire vent connector back to the chimney and

clean if necessary.

3. Inspect the chimney for soot, debris and other unsafe condi-

tions of the chimney and take the necessary action.

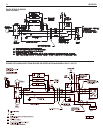

4. Remove the flue collector by first removing the top jacket

panel.The flue collector is held in place by two hex 1/4-20

screws. Remove the screws and carefully remove the flue col-

lector

.Try not to disturb the flat fiberglass rope under the flue

collector

.

5. When necessary to clean the combustion chamber you must

first CLOSE the suction valve (and return valve if two pipe).

Then disconnect the oil lines from the b

urner.The flexible

electr

ic conduit connected from the junction box on the boiler

to the burner via a plastic connector must be disconnected

from the burner by grasping the plastic half of the connector

closest to the fle

xible conduit and gently pulling it in the direc-

tion of the conduit until it is disconnected.

Remove the single

3/8-16 he

x head scre

w on the LEFT side of the s

winging door.

You will need a 9/16” drive socket. Open the door to complete-

ly expose the combustion chamber for thorough cleaning and

for inspection of target wall, blanket (provided in certain mod-

els; see rating plate), main cast iron burner door insulation

and burner door fiberglass sealing rope. If combustion cham-

ber parts above are badly deteriorated then replace with origi-

nal factory parts available at your distributor.

6. Use the flue brush to clean the pinned flueways between the

sections.† A wire brush may be used to remove any carbon

accumulation that may have developed in the combustion

chamber.Vacuum the loose soot and debris from the boiler.

7. Inspect the burner combustion head. Clean if necessary and

make sure all the adjustments are correct. (See burner data

pages for the b

urner installed.) Replace oil nozzle with new

one and readjust electrodes.To insure proper burner opera-

tion ONLY THE NOZZLES SPECIFIED IN THIS MANUAL OR

ON THE BURNER LABEL SHOULD BE USED FOR

REPLACEMENT.

8. Close main cast iron b

urner door (door on which burner is

mounted). Make sure that the entire seal (fiberglass rope) is

making good contact with the boiler casting when replacing

3/8-16 x 1” long hex head bolt and tightening.

9. Check the flue collector seal.This is the flat rope seal on top of the

heat exchanger. The rope must be in place adjacent to the long boss-

es on front and rear sections and adjacent to the short bosses on the

intermediate sections. The rope should be directly under the flue col-

lector flanges when the flue collector is replaced. Use the two 1/4-20

x 3/4” washer hex head screws to fasten the flue collector. In order to

assure a proper seal be sure that the flue collector is compressing

the flat rope and not hanging up on the section bosses.Tighten the

two screws.

D. If boiler room is damp, provide ventilation.

II. PROVIDING PROTECTION FOR FREEZING

Anti-freeze is sometimes used in hydronic heating systems to pro-

tect against freeze-up in the event of power failure, or safety control

shutdown when the building is unoccupied. It should be recognized

that unless the building is kept above freezing temperature by some

means, the plumbing system is not protected.

PROPYLENE GLYCOL is used in the quick-freeze food industry; it is

pr

actically non-toxic. Its use may be permitted when tankless heaters

are used. When anti-freeze must be used, inhibited propylene glycol

is recommended. Useful information on the characteristics, mixing

proportions, etc. of glycol in heating systems is given in Technical

Topics No. 2A, available from the Hydronics Institute, 35 Russo

Place, Berkeley Heights, N.J. 07922. Consult glycol manufacturers

for sources of propylene glycol. DO NOT use ethylene glycol

because it is to

xic.

III.

OIL BURNER

Inspect and clean annually and following any period of improper

operation. Recheck and adjust settings as specified for burner model

and nozzle size. Set burner air and draft regulator, using test instru-

ments to obtain recommended CO

2

and draft without smoke.

Ref

er to page 8.

IV

. GENERAL MAINTENANCE

These operations are recommended to be performed at regular

inter

vals:

A.

BOILER HEATING SURFACES: clean off all coatings found.

Reseal covers.

B. BOILER CONTROLS: check contacts, settings, correct

functioning.

C

. PIPING: check piping and accessories for leaks.

D

.

CHIMNEY or STUB

VENT and BREECHING:

check for obstruc-

tions and leaks.

E. COMBUSTION AIR TO BURNER: check for continued POSITIVE

supply of air as required.

Air needs are greatest in coldest

w

eather

.

Refer to AIR SUPPLY, page 3.

F

. WATER SYSTEM: check

1. System to be full of water and pressure to remain stable

(betw

een 12 psi and 25 psi).

2. Air-control system: noise and air binding in radiation should

not occur.

3. Water lines: slightest leaks should be corrected.

4. Low water cut-off, for operation (see instructions furnished

with unit). See page 9.

G.STEAM SYSTEM: check

1.

Lo

w w

ater cut-off, for operation (see instructions furnished

with unit). See page 9.

2. Check pressure cut-off for operation. See page 10.

3. Any unusual water conditions. Obtain water analysis and treat

water.

H.BOILER ROOM AIR SUPPLY: air vents should be open and free

of obstruction. See page 3.

†

A flue brush (2-1/4" dia.) is supplied with boiler. Replacements

are available from dealer or hardware stores.

C

ARE AND MAINTENANCE