4

EUTECTIC EC-10 DV

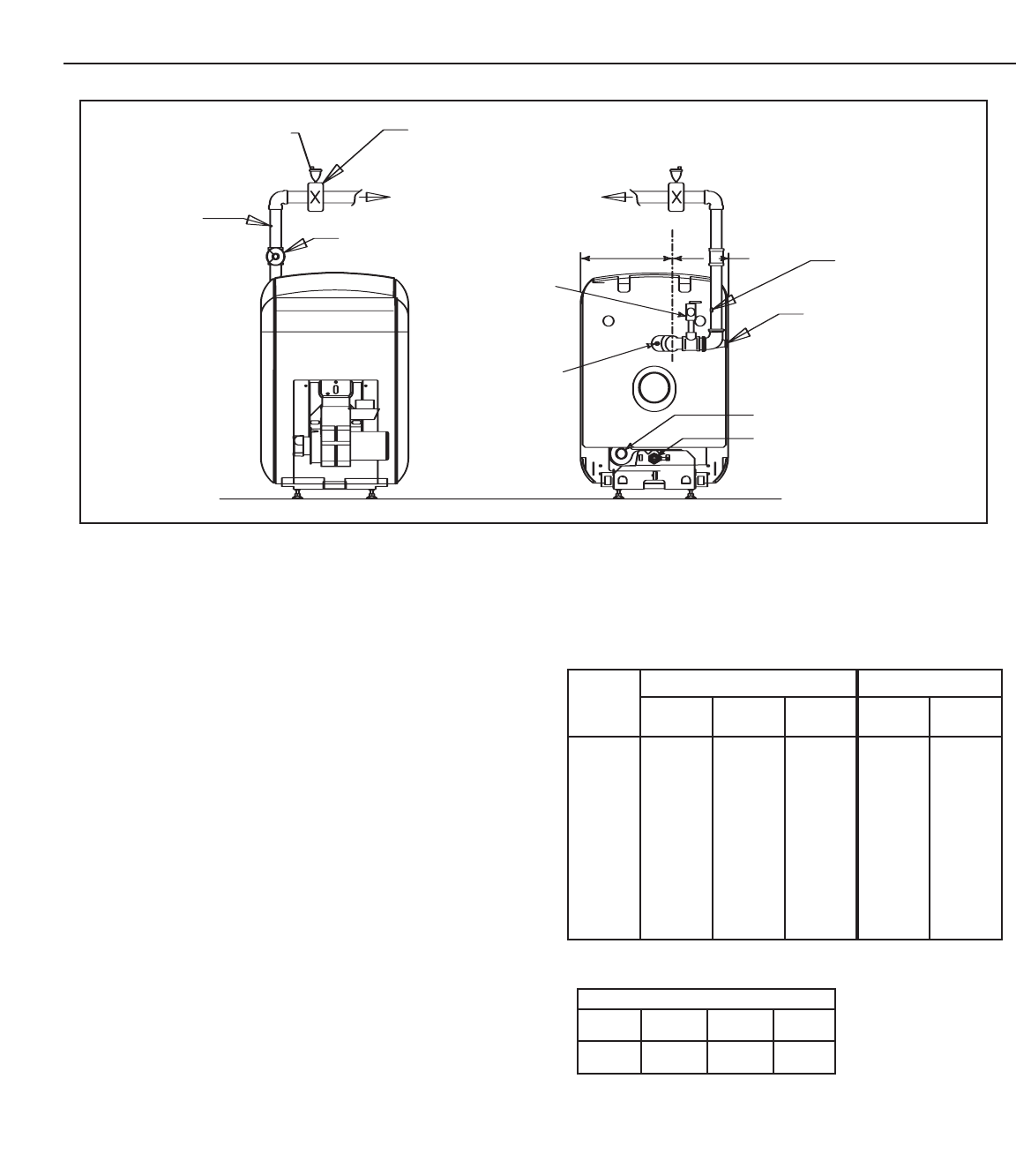

If system pressure needs further control, add an additional tank or install a

larger capacity tank. The automatic air vent should be installed in the top of

the boiler, as in figure 3.

B. CONVENTIONAL COMPRESSION TANKS (non-diaphragm type) are

used to control system pressure in an AIR COLLECTING SYSTEM. Within

the system, after initial start-up and venting, air is collected in the tank and

acts in contact with the water to control pressure. Air is not vented from this

system. If system pressure needs further control, add another tank in

parallel with the original tank or install a large capacity tank. Locate the

tank at the inlet end of the pump near the boiler. (See figure 3)

C. HOT WATER RADIATION VENTING - Manual air vents should be installed

at the top of all "drops" (where piping goes downward). Air must be vented

or purged from all zone lines to permit proper system heating.

D. PUMP LOCATION - Locating low-head pump(s) on return to boiler is

acceptable for smaller boiler sizes in residences of one or two stories.

The pump location sho

wn in figure 3 is required in large

, m

ulti-stor

y

building installations, especially when high-head pumps are used.

IMPORTANT: Hot water heating systems containing high water volume, such

as w

ould occur with cast iron r

adiation, require special care with air elimina-

tion. The circulator pump should be located on the boiler supply pipe and the

expansion tank and air scoop should be located near the pump suction.

INSTALLING THE BURNER

See Bur

ner Data, pages 8-9, and Bur

ner Man

ual supplied with b

ur

ner. If

burner is not mounted as received, mount to boiler, placing flange over

mounting studs

. Use gasket between flange and boiler. Distance between

flange and nose of burner must be as shown on pages 8-9. Check to see

that nozzle and settings are as given in burner data tables, pages 8-9.

3

⁄

8

– – – 0.430 0.0075

1

⁄

2

40 0.622 0.0157 0.545 0.0121

5

⁄

8

– – – 0.666 0.0181

3

⁄

4

40 0.824 0.0277 0.785 0.0251

1 40 1.049 0.0449 1.025 0.0429

1

1

⁄

4

40 1.380

0.0779

1.265 0.0653

1

1

⁄

2

40 1.610 0.106 1.505 0.0924

2

40

2.067

0.174

1.985 0.161

2

1

⁄

2

40 2.469 0.249 2.465 0.248

3 40 3.068 0.384 2.945 0.354

Nominal

pipe Dia.

Pipe

Schedule

Pipe ID

Inch

Gal. per

Lin.Ft.

Pipe ID

Inch

Gal. per

Lin. Ft.

Standard Steel Pipe Copper Pipe

VOLUME OF WATER IN STANDARD PIPE OR TUBE

1

3-31/32

7

-11/16

Relief valve 3/4

1/2” NPT Tapping

for FeedValve and

E

xpansionTank

1-1/4 NPT

r

eturn tapping

Drain outlet

Panel Mounted

T

ridicator Temperature

Sensor Well

A

ir Eliminator

a

s per Manufacturer

Specifications

To Circ.(s)

and Zones

1

-1/4”

NPT

Supply

Automatic

Air Vent

S

uppy Pipe Mounted

Tridicator

Panel Mounted

Tridicator Pressure

Sensor Well

Figure 3. Air Eliminating System or Alternating Collecting System

EC-13 EC-14

EC-15 EC-16

5 6.5 8 8.5

WATER CONTENT OF BOILER (GALLONS)