E

UTECTIC EC-10 DV

3

BOILER LOCATION

Provide a level, solid foundation for the boiler.

A. The foundation must be capable of supporting the weight of

the boiler when filled with water:

* Includes burner, circulator and controls

B. These boilers have full wet base sections which surround fire-

box for maximum heat absorption of burning fuel, and low floor

temperature.

C

. If boiler is to be located over buried conduit containing electric wires

or telephone cables, consult local codes or the National Board of Fire

Underwriters for specific requirements.

MINIMUM CLEARANCE

Provide accessibility clearance of 24" from surfaces requiring servicing (top

and front) and 18" on any side requiring passage.The boiler shall be

installed with the following MINIMUM clearances from combustible materials:

BACK AND SIDES- 6"

NOTE: Except in closets and alcoves, clearances above in (A) and

(B) may be reduced by providing forms of protection as specified in

NFPA 31, latest edition.

VENTING REQUIREMENTS

• The terminal shall not be closer than 3 feet above or 10 feet horizon-

tally from any forced air inlet into the building.

• The terminal shall not be closer than 4 feet below, 4 feet horizontally

or 1 foot above any door, window or gravity air inlet into the building.

• The terminal shall not be less than 3 ft from an inside corner of an “L”

shaped building.

• The terminal shall not be less than 7 ft above grade when located

adjacent to public walkways.

• The terminal shall not be less than 2 ft from an adjacent building.

• The terminal shall be located at a height not liable to blockage from

leaves, snow or other debris, at least 1 ft above grade or anticipated

snow line.

• The terminal shall be positioned so that flue gases are not directed

where they can jeopardize people, overheat combustible structures

or enter buildings.

• Vent terminal should be away from shrubbery or other obstructions

that would prevent free air flow to and from vent terminal.Do not ter-

minate v

ent under dec

ks

, stairways or car ports. When ever possible,

locations under windows should be avoided.

•

V

ent ter

mination should not be mounted directly abo

v

e or within 3 ft

horizontally from an oil tank vent.

BOILER INTERNAL BAFFLES

IMPOR

TANT: EC-10 series boilers Direct Vent version is different from

standard series. Direct Vent version boilers usually have fewer internal cast

iron baffles.

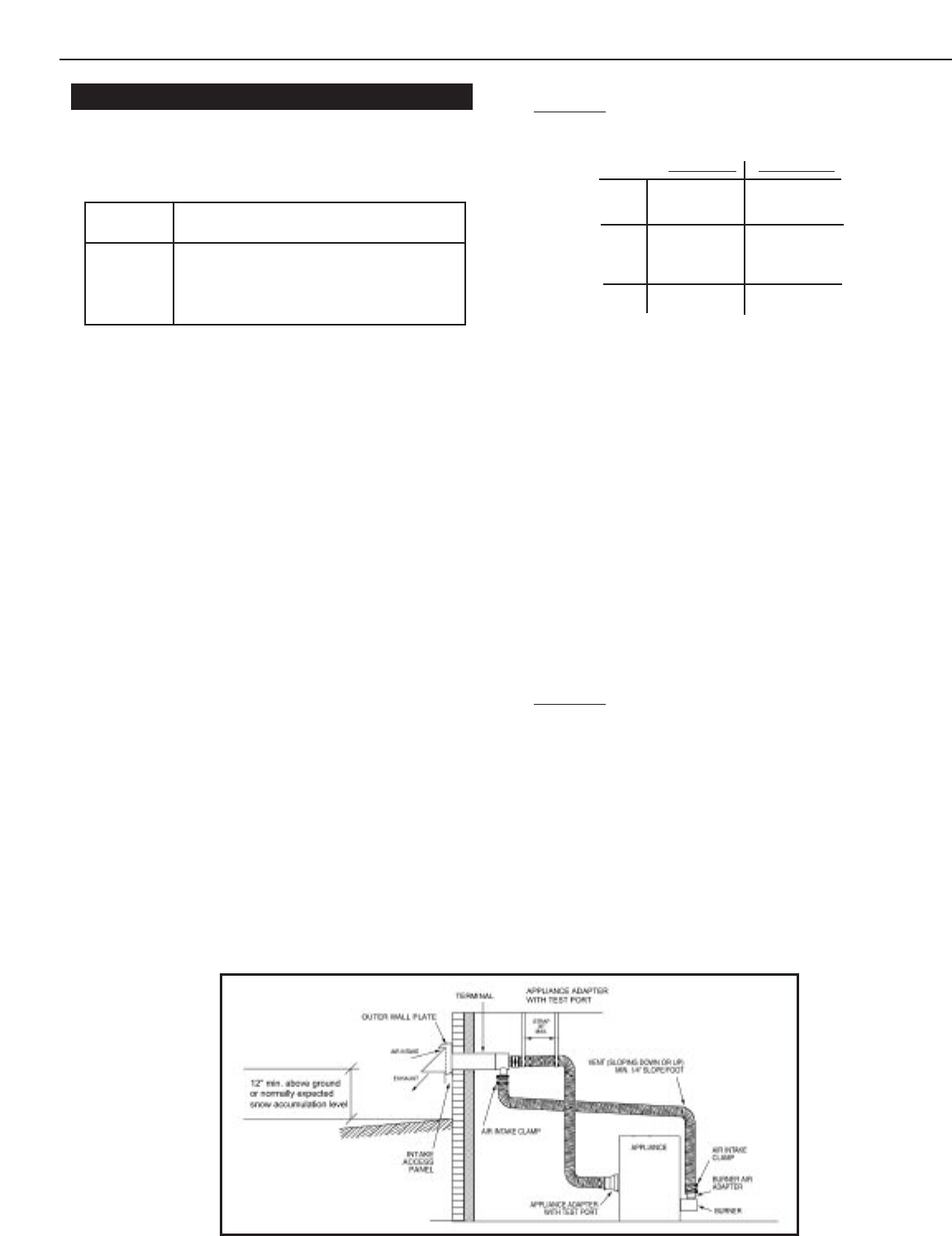

VENT PIPING

A. The vent piping minimum bend radius is 12”.

B. Place metal strapping every 36” to support vent pipe and prevent it

from sagging.

C. Maximum wall thickness is 14”. Contact Slant/Fin Corp. for

recommendations in case of thicker wall.

D. Gases will form white plume in winter. Plume could obstruct window view.

E. Prevailing winds could cause freezing of condensate and water/ice

buildup on building, plants or roof.

F

. Locate or guard vent to prevent accidental contact by people or pets, and

condensate from damaging exterior finish.

G.Do not terminate vent in window well, stairwell, alcove, courtyard, or other

recessed areas.

All venting kits must be double wall construction for the flue gas piping.

Field

Controls is the only approved manufacturer for venting kits. When installing

the vent kits the manufacturers instructions must be followed.

I

NSTALLING WATER TRIM

Notes: Jacket must be installed on boiler units prior to installation of trim.

PIPING

IMPORTANT: Boilers are to be used with closed system. Any application

that uses water from system, causes the introduction of a frequent supply of

fresh water into the boiler. This will cause damage to the boiler. Use of heat

exchangers will prevent this damage.

PIPING FOR WATER UNITS

NOTE: On knock down boiler only, jacket may be installed after return pip-

ing connection, but must be installed prior to adding trim & supply piping.

I. CIRCULATING SYSTEM

A. FORCED CIRCULATION hot water heating system: Use the top

tapping as supply tapping, and use the rear bottom tappings for

the return.

B. A FLOW CONTROL VALVE will prevent gravity circulation.

II. AIR CONTROL SYSTEMS

A. DIAPHRAGM-TYPE COMPRESSION TANKS are used to control

system pressure in an AIR ELIMINATING SYSTEM: an automatic

air vent is used to REMOVE air from the system water. See figure 3.

Figure 2. Typical Installation

I

NSTALLATION REQUIREMENTS

Boiler Approximate Total Weight of Boiler

Size Assembly*, filled with water

EC-13-DV 353

EC-14-DV 426

EC-15-DV 501

EC-16-DV 575

E

C-13

E

C-14 & 15

EC-16

S

tandard V

e

rsion

(

3) Baffle Plates

(

2) Baffle Plates

c

enter & right side

when viewing from

front

(0)

D

irect V

e

nt V

e

rsion

(

2) Baffle Plates center

& right side when

viewing from front

(

0)

(0)