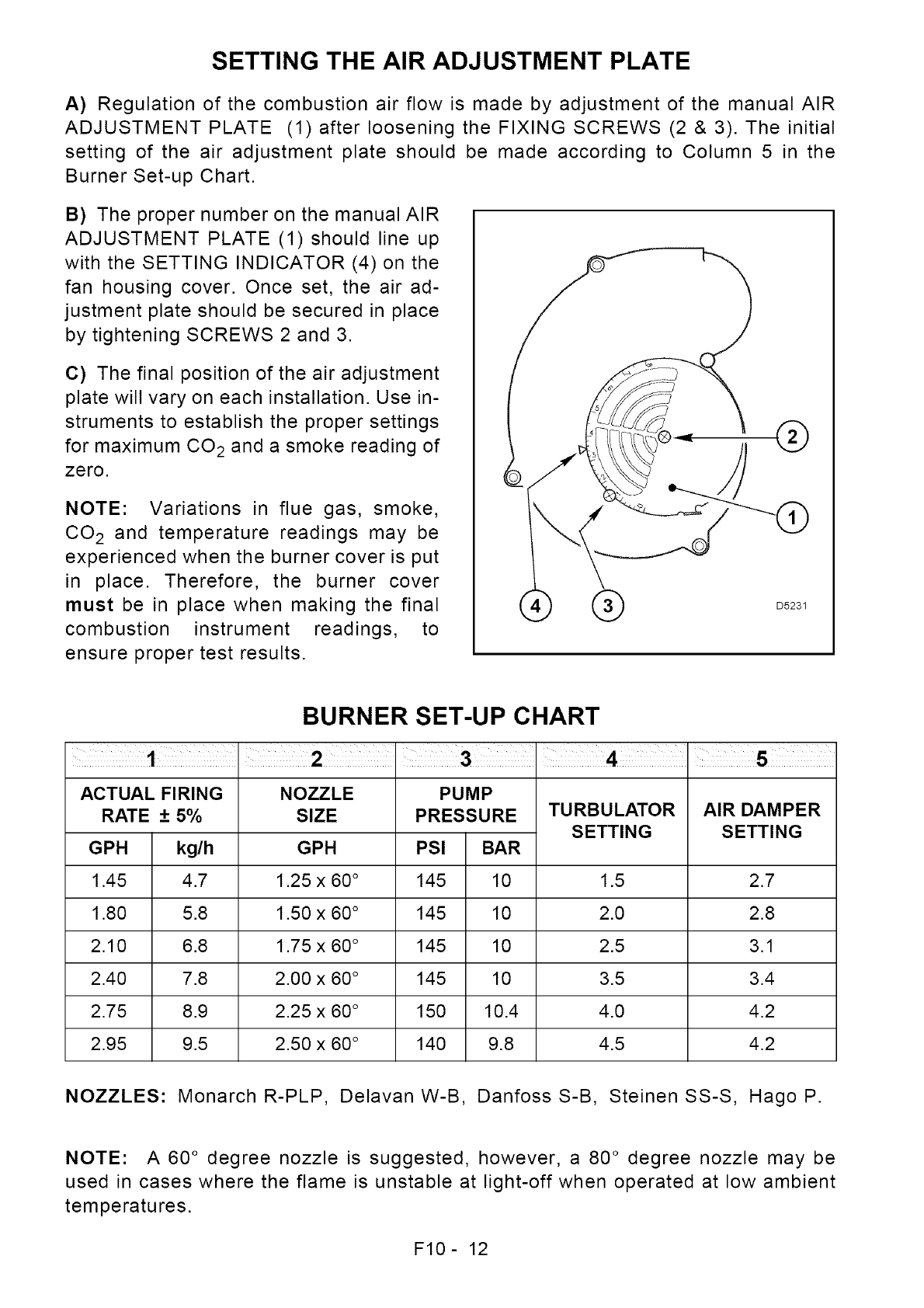

SETTING THE AIR ADJUSTMENT PLATE

A) Regulation of the combustion air flow is made by adjustment of the manual AIR

ADJUSTMENT PLATE (1) after loosening the FIXING SCREWS (2 &3).The initial

setting of the air adjustment plate should be made according to Column 5 in the

Burner Set-up Chart.

B) The proper number on the manual AIR

ADJUSTMENT PLATE (1) should line up

with the SETTING INDICATOR (4) on the

fan housing cover. Once set, the air ad-

justment plate should be secured in place

by tightening SCREWS 2 and 3.

C) The final position of the air adjustment

plate will vary on each installation. Use in-

struments to establish the proper settings

for maximum CO 2 and a smoke reading of

zero.

NOTE: Variations in flue gas, smoke,

CO 2 and temperature readings may be

experienced when the burner cover is put

in place. Therefore, the burner cover

must be in place when making the final

combustion instrument readings, to

ensure proper test results.

®

D5231

BURNER SET-UP CHART

ACTUAL FIRING

RATE + 5%

GPH

1.45

1.80

2.10

2.40

2.75

2.95

kg/h

4.7

5.8

6.8

7.8

8.9

9.5

NOZZLE

SIZE

GPH

1.25 x 60°

1.50 x 60°

1.75 x 60°

2.00 x 60 °

2.25 x 60 °

2.50 x 60 °

PUMP

PRESSURE

PSI BAR

145 10

145 10

145 10

145 10

150 10.4

140 9.8

TURBULATOR

SETTING

AIR DAMPER

SETTING

1.5 2.7

2.0 2.8

2.5 3.1

3.5 3.4

4.0 4.2

4.5 4.2

NOZZLES: Monarch R-PLP, DelavanW-B, DanfossS-B, SteinenSS-S, HagoP.

NOTE: A 60 ° degree nozzle is suggested, however, a 80 ° degree nozzle may be

used in cases where the flame is unstable at light-off when operated at low ambient

temperatures.

F10- 12