Regency

®

P42-4 Zero Clearance Direct Vent Gas Fireplace 9

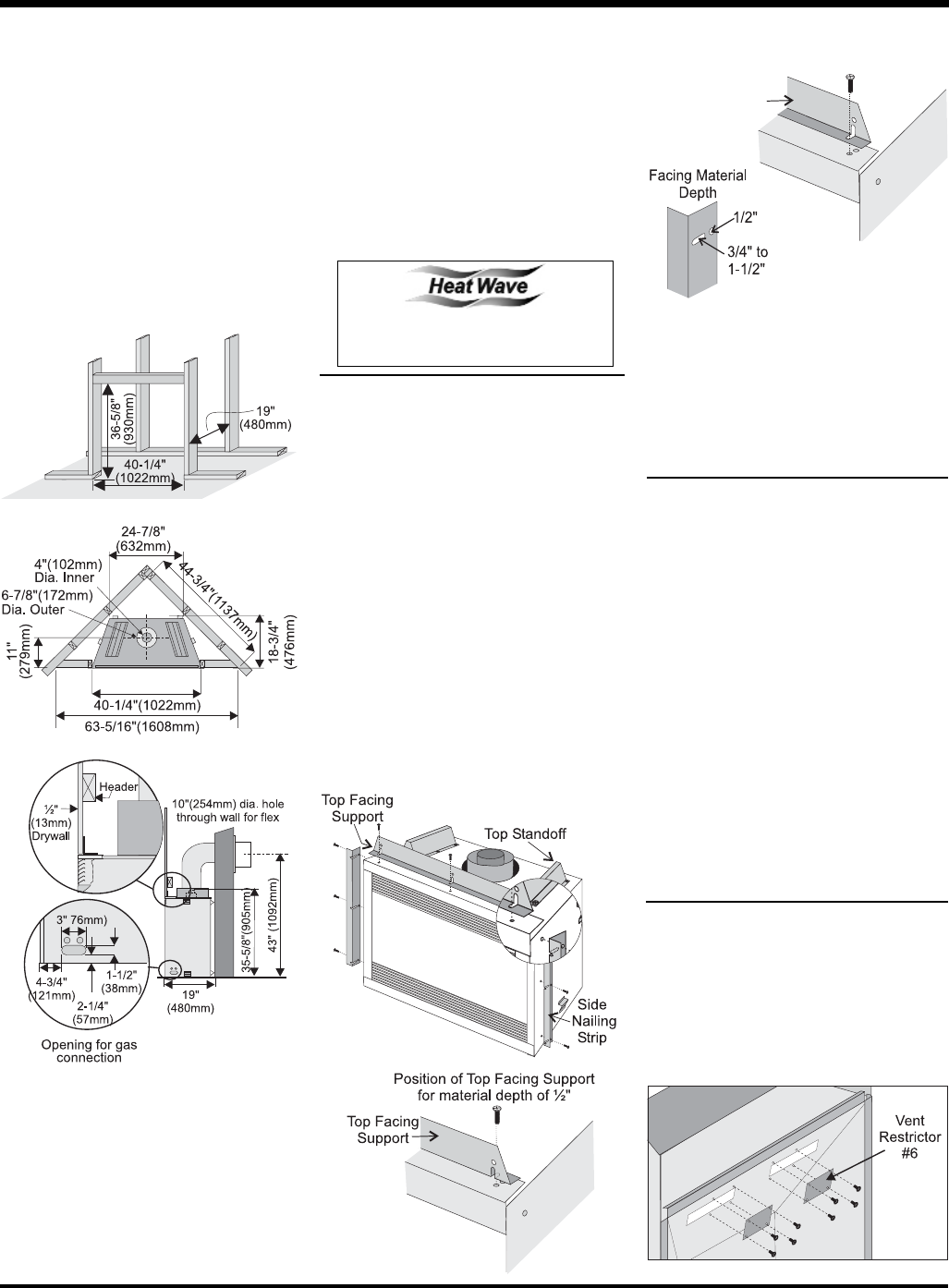

Position of Top Facing Support

for material depth of 3/4” to 1-1/2"

T

op Facing

Support

TOP ASSEMBLY &

NAILING STRIPS

The Top Facing Support and Side Nailing Strips

must be correctly positioned and attached before

the unit is slipped into position.

1) The top standoffs are shipped installed.

2) The Top Facing Support and the 2 Side

Nailing Strips can be installed at different

depths depending on the width of your facing.

Match the depths of the top facing support

and the side nailing strips.

a) Mount Top Facing Support using the 3

supplied screws into the 3 pre-punched

screw holes on the top front of the unit.

See Diagrams 2 & 3 for the proper

position of the Top Facing Support for

the various material depths.

Diagram 1

Diagram 2

Diagram 3

Diagram 4

INSTALLATION

5) The unit does not have to be completely

enclosed in a chase. The clearance on top

of the unit from the top standoffs is 0" so

combustible building materials can be laid

directly on top of the standoffs. You must

maintain these clearances from the vent

to combustible materials: Flex Termination

clearance 1-1/2" (38mm), Simpson Dura-Vent

clearance or (1-1/4" (32mm). Combustible

materials can be laid against the side and

back standoffs and the fi replace base.

b) Mount the Side Nailing Strip using the 3

supplied screws into the 3 screw holes

or slots (diagram 4) on the side of the

unit and repeat for the other side. Use

the hole for a 1/2" (13mm) thick facing

material and the slot for a range of

thickness from 3/4" to 1-1/2" (25mm to

38mm).

VENTING

INTRODUCTION

The P42 uses the "balanced fl ue" technology

Co-Axial system. The inner liner vents products

of combustion to the outside while the outer

liner draws outside combustion air into the

combustion chamber thereby eliminating the

need to use heated room air for combustion and

losing warm room air up the chimney.

Note: These flue pipes must not be

connected to any other appliance.

The gas appliance and vent system must be

vented directly to the outside of the building,

and never be attached to a chimney serving a

separate solid fuel or gas burning appliance.

Each direct vent gas appliance must use it's own

separate vent system. Common vent systems

are prohibited.

VENT RESTRICTOR

A vent restrictor may be required. Check

the diagrams in the "Rigid Pipe Venting

Arrangements" section to determine if the #6

restrictor is needed for your vent confi guration.

If required, attach the 2 piece #6 restrictor

using 4 screws per piece to the inside top of

the fi rebox.

Note: 43" (1092mm) is the minimum height

for fl ex termination and Rigid Pipe

terminations.

Diagram 1

FRAMING AND

FINISHING

1) Determine the total thickness of facing

material (ie. drywall plus ceramic tiles) to

allow the fi nished surface to be fl ush with

the front of the unit. Total facing thickness

can vary from 1/2" (13mm) to 1-1/4" (32mm)

thick.

2) Frame in the enclosure for the unit with

framing material. The framed opening for

the assembled kit is 36-5/8" high x 40-1/4"

wide x 19" deep (930mm H x 1022mm W

x 483mm D). See Diagram 1.

3) For exterior walls, insulate the enclosure to

the same degree as the rest of the house,

apply vapour barrier and drywall, as per

local installation codes. (Do not insulate

the fi replace itself.)

4) The top louvers must not be closer than

36" (914mm) to the ceiling.

The HeatWave Duct Kit has different

clearance and framing requirements,

check the HeatWave manual for details.