3. INSTALLATION PROCEDURES

CODE REQUIREMENTS

Installation must be in accordance with local

codes, or, in the absence of local codes, with the latest

editions of the National Fuel Gas Code, ANSI Z223.1,

and the National Electrical Code, ANSI/NFPA 70. In

Canada installations must conform with the current

CAN/CGA B149.1 or .2 and the Canadian Electrical

Code Part 1 CSA C22.2 No.1. Where required by the

authority having jurisdiction, the installation must con-

form to American Society of Mechanical Engineers

Safety Code for Controls and Safety Devices for Auto-

matically Fired Boilers, No. CSD-1.

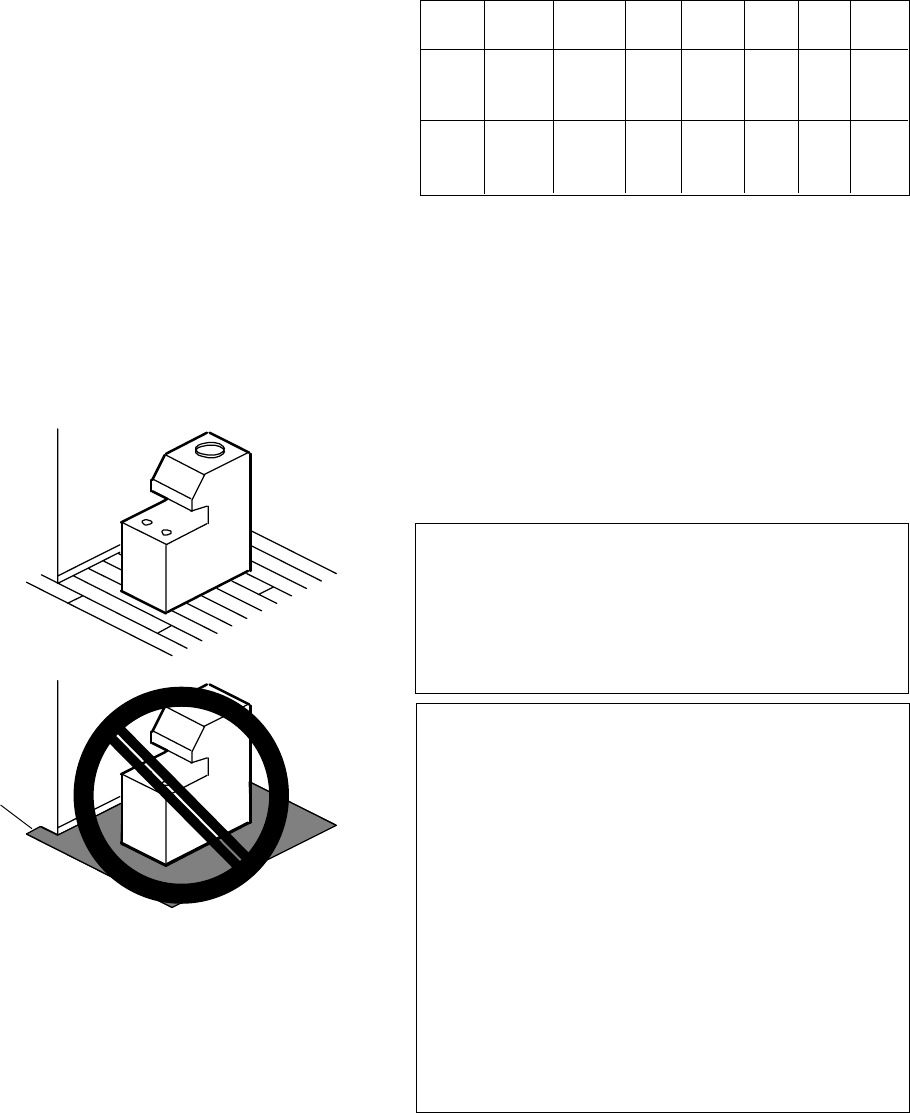

MOUNTING BASE

Boiler should be mounted on a level surface. Each

boiler is designed with a built-in sub-base approved for

mounting the boiler on combustible flooring. Boiler

must NOT be installed on carpet flooring.

CARPET

NOTE: The boiler should be located in an area where

water leakage will not result in damage to the area

adjacent to the appliance or to the structure. When

such locations cannot be avoided, it is recommended

that a suitable drain pan, adequately drained, be in-

stalled under the appliance. The pan must not restrict

air flow.

In addition, the boiler shall be installed such that

the gas ignition system components are protected from

water (dripping, spraying, rain, etc.) during appliance

operation and service (circulator replacement, control

replacement, etc.)

4

CLEARANCE REQUIREMENTS

1) Minimum Clearances From Combustible Materials

Model Floor Front Back Right Left Top Flue

No. Vent

0030

0042 Comb. 4" 6" 6" 6" 16" 6"

0066

0090

0135 Comb. Alcove 6" 6" 6" 16" 6"

0180

2) A front clearance of at least 24" is recommended for

adequate service of burner-tray and controls.

3) Except for carpeted flooring, boilers are certified for

installation on combustible floors.

4) For un-insulated hot water pipes, maintain a 2"

clearance, or consult local authority having jurisdic-

tion.

COMBUSTION/VENTILATION AIR

WARNING: Air supply to the boiler room must not be

affected by mechanical exhaust vents located in other

parts of the house, such as kitchen or bathroom fans,

or attic blowers. Mechanical exhaust vents may create

a negative pressure condition in the boiler room that

can become a hazard of asphyxiation, explosion or fire.

CAUTION: Combustion air must not be contaminated

by corrosive chemical fumes which can damage the

boiler. Measures must be taken to prevent the entry of

corrosive chemical fumes to the combustion and ven-

tilation air supply. Such chemicals include, but are not

limited to, chlorinated and/or fluorinated hydrocarbons

such as found in refrigerants, aerosol propellants, dry-

cleaning fluids, degreasers, and paint removers. Other

harmful elements may come from bleaches, air fresh-

eners, or mastics. Vapors from these types of products

can form corrosive acid compounds when burned in a

gas flame. The resulting acid condensate can damage

or substantially reduce the life of the heater. It may be

necessary to provide outside air directly to the heater in

order to avoid this problem.

1) The boiler must be provided with adequate supply of

air for proper combustion and ventilation in accor-

dance with Sec. 5.3, of the latest edition of the

National Fuel Gas Code, ANSI Z223.1, or appli-

cable provisions of the local building codes.

CARPET

Fig.# 8196.0p