The gas valve is provided with pressure taps to

measure gas pressure upstream of the gas valve and

downstream which is the same as the manifold pres-

sure.

WATER CONNECTIONS & SYSTEM PIPING

The pipe size for water connections is shown on

page 3. Typical piping systems are shown on pages 11

to 13.

The boiler is supplied as standard with a circulator

and a built -in by-pass to insure the required minimum

water flow in the boiler. The by-pass on models H-0135

and H-0180 is provided with an adjustable valve that is

factory set in the full open position. The handle is

shipped loose. The full open position is appropriate for

most systems, and insures adequate flow through the

boiler. If system flow is inadequate, (indicated by

excessive temperature drop through the system) the by-

pass valve can be throttled slightly. Care must be taken

against over throttling which may lead to inadequate

flow through the boiler and boiler harmonics (a humming

sound from the heat exchanger). If adequate system

flow cannot be obtained without causing harmonics, an

additional pump is required. The factory mounted

circulator will provide adequate water flow for systems

designed at a 20°F temperature drop, and system

pressure drop or head not exceeding that is shown

below.

When the total system head exceeds the available

head pressures, a primary/secondary pumping system

is recommended.

The minimum boiler operating temperature

should be 105°F. When operating at low tempera-

ture applications, ÐT (temperature rise) must be

20°F or less.

Propylene glycol solution is commonly used in the

heating system when freeze protection is required. This

will affect the system design and pump performance. As

a "rule of thumb", 50% solution of propylene glycol will

require the system flow (GPM) to increase by 14%, and

the system head (Ft/Wtr) by 23% in order to maintain the

same heat transfer load.

10

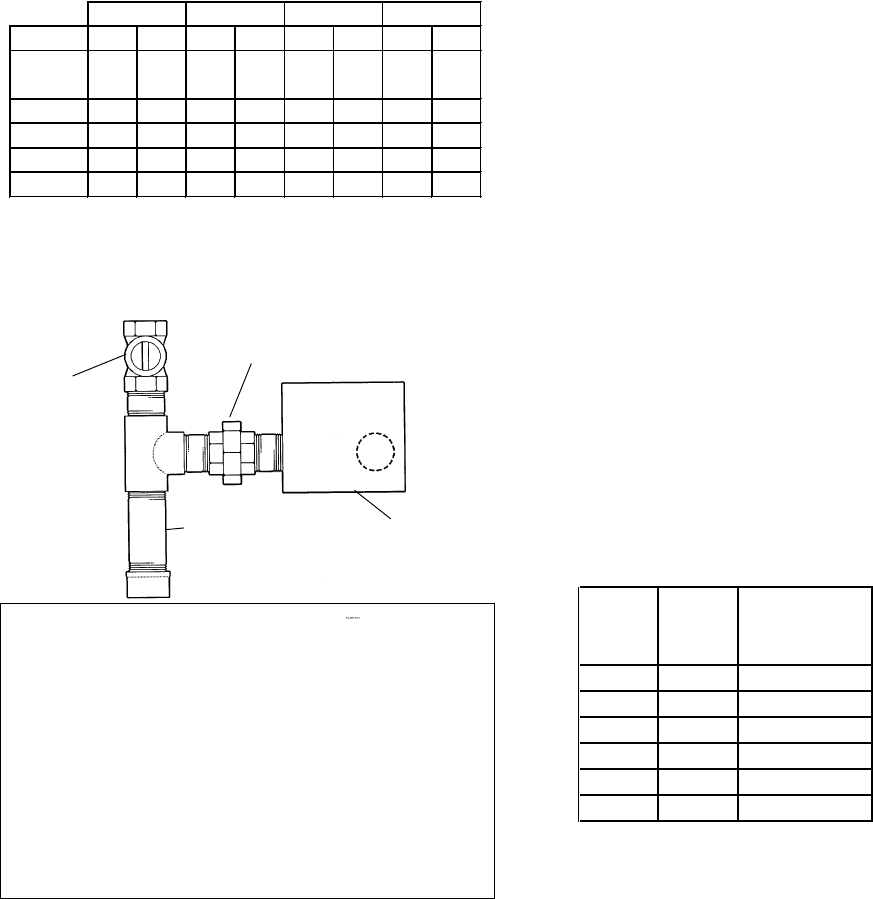

GAS SUPPLY CONNECTIONS

The inlet gas connection of the boiler gas valve is

1/2". Provide an adequate gas piping supply line no

smaller than 1/2", according to the chart below:

Maximum Equivalent Pipe Length (Feet)

Gas piping must have a sediment trap ahead of the

boiler gas controls, and a manual shutoff valve located

outside the jacket. All gas piping should be tested after

installation in accordance with local codes.

CAUTION: The boiler and its manual shut off valve must

be disconnected from the gas supply during any pres-

sure testing of that system at test pressures in excess

of 1/2 psig (3.45 KPA). Dissipate test pressure in the

gas supply line before reconnecting the boiler and its

manual shut off valve to gas supply line. FAILURE TO

FOLLOW THIS PROCEDURE MAY DAMAGE THE

GAS VALVE. OVER PRESSURED GAS VALVES ARE

NOT COVERED BY WARRANTY. The boiler and its

gas connections shall be leak tested before placing the

appliance in operation. Use soapy water for leak test.

DO NOT use open flame.

NOTE: Do not use teflon tape on gas line pipe thread.

A flexible sealant suitable for use with Natural and

Propane gases is recommended.

GAS PRESSURE-SPECIFICATIONS

Inches W.C. Regulator

Min. Max. Setting

Natural 7.0 14.0 3.5

Propane 12.0 14.0 11.0

Sediment Trap Gas Valve

Manual Union

Valve

Fig. # 8192.0

MODEL NAT PRO NAT PRO NAT PRO NAT PRO

0030 &

0042

125 350 500 - - - - -

0066 60 160 175 460 - - - -

0090 30 80 125 325 400 - - -

0135 15 40 60 155 200 500 - -

0180 - 20 35 90 115 300 425 -

1/2" Pipe 3/4" Pipe 1" Pipe 1 1/4" Pipe

System Maximum

Models Flow System Head

(GPM) (Ft/Wtr)

H-0030 2.5 9.0

H-0042 3.5 8.0

H-0066 5.3 8.5

H-0090 7.3 6.5

H-0135 11.0 10.0

H-0180 14.6 7.0