10.2.2. R410A Tools

1. Copper tube gauge for clearance adjustment

(used when flaring with the conventional flaring tool (clutch

type))

• This gauge makes it easy to set the clearance for the

copper tube to 1.0-1.5 mm from the clamp bar of the

flaring tool.

2. Flaring tool (clutch type)

• In the R410A flaring tool, the receiving hole for the

clamp bar is enlarged so the clearance from the clamp

bar can be set to 0-0.5 mm, and the spring inside the

tool is strengthened to increase the strength of the pipe-

expanding torque. This flaring tools can also be used

with R22 piping, so we recommend that you select it if

you are buying a new flaring tool.

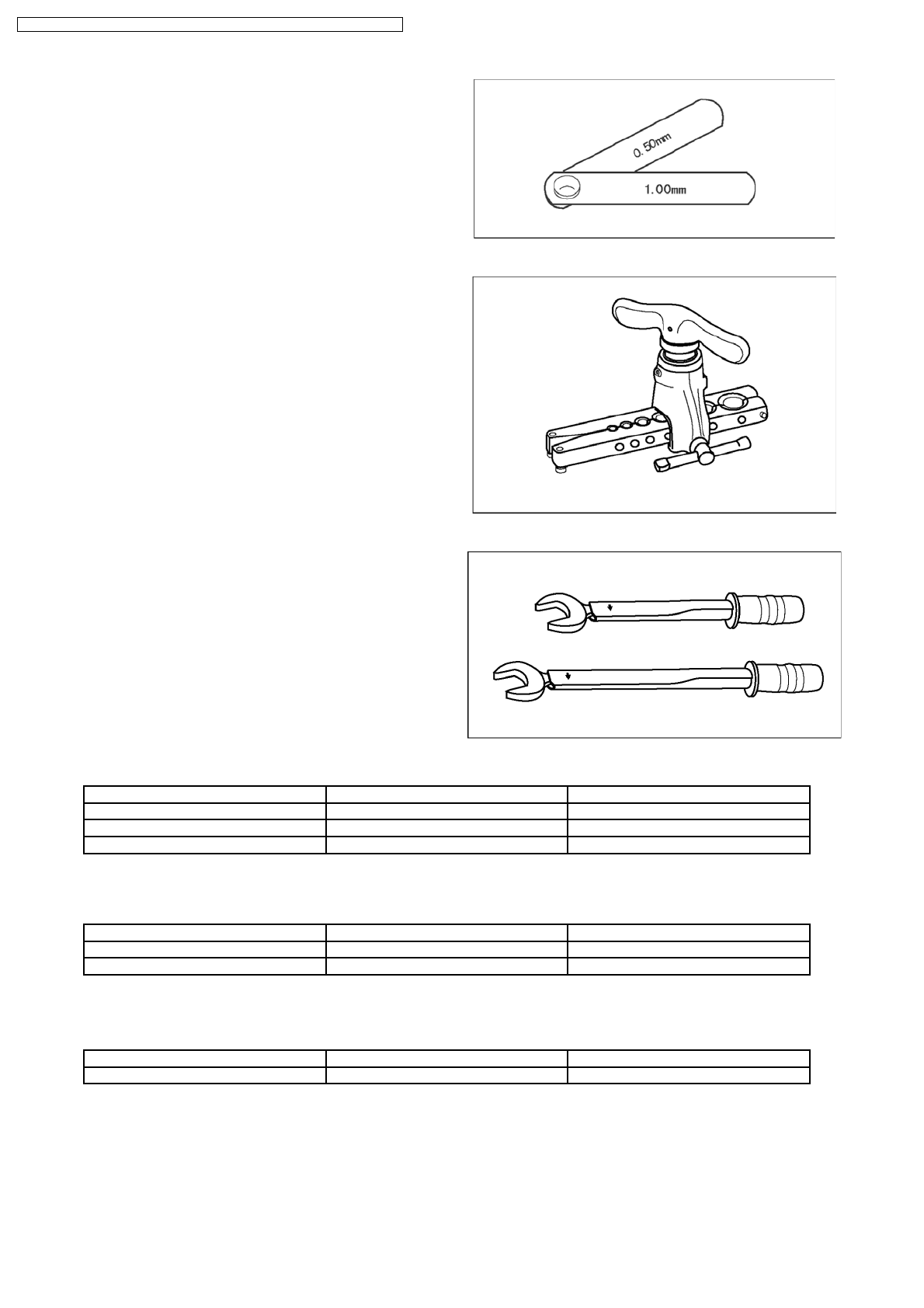

3. Torque wrenches

4. Manifold gauge

Fig. 1 Copper tube gauge for clearance adjustment

Fig. 2 Flaring tool (clutch type)

Fig. 3 Torque wrenches

Table 5

Conventional wrenches R410A wrenches

For 1/4 (opposite side x torque) 17 mm x 18 N.m (180 kgf.cm) 17 mm x 18 N.m (180 kgf.cm)

For 3/8 (opposite side x torque) 22 mm x 42 N.m (420 kgf.cm) 22 mm x 42 N.m (420 kgf.cm)

For 1/2 (opposite side x torque) 24 mm x 55 N.m (550 kgf.cm) 26 mm x 55 N.m (550 kgf.cm)

• Because the pressure is higher for the R410A type, the conventional type cannot be used.

Table 6 Difference between R410A and conventional high / low-pressure gauges

Conventional gauges R410A gauges

High-pressure gauge (red) -76 cmHg - 35 kgf/cm

3

-0.1 - 5.3 Mpa -76 cmHg - 53 kgf/cm

3

Low-pressure gauge (blue) -76 cmHg - 17 kgf/cm

3

-0.1 - 3.8 Mpa -76 cmHg - 38 kgf/cm

3

• The shape of the manifold ports has been changed to prevent the possibility of mistakenly charging with another type of

refrigerant.

Table 7 Difference between R410A and conventional manifold port size

Conventional gauges R410A gauges

Port size 7/16 UNF 20 threads 1/2 UNF 20 threads

44

CS-E15DB4EW CU-E15DBE / CS-E18DB4EW CU-E18DBE / CS-E21DB4ES CU-E21DBE