3

CABLE CLAMP INSTALLATION (CONTINUED)

A. Tighten the top hex nut on both cable ends. Using a 3/16" wrench or socket, hold the

cable end in position while tightening the top hex nut with a 1/2" wrench or socket. is

will keep the cable from twisting as the hex nuts are tightened.

4

SUPPORTING THE WINDOW

B. Remove the temporary bracing. Check the window for level, plumb, sash reveal and

operation. Readjust, if needed.

Note: Be sure to use the temporary support when readjusting the hex nuts.

C. Remove blocking from under the seat board.

D. Tighten the locking (bottom) nut on both cable ends and

remove the temporary support once the nal position is found.

DO NOT cut the threaded end o the cable as this will prevent

future adjustment should it be needed.

E. Installation of knee braces is recommended to help support

the weight of the bay/bow unit. Weight calculations must take

into account the weight of the items that may be placed on

the seat board of the bay/bow unit. If the upper roof/framing

members are not capable of supporting 1,300 lbs. or if more

than 500 lbs. will be put on the seat board, knee braces must be

used in addition to the cables.

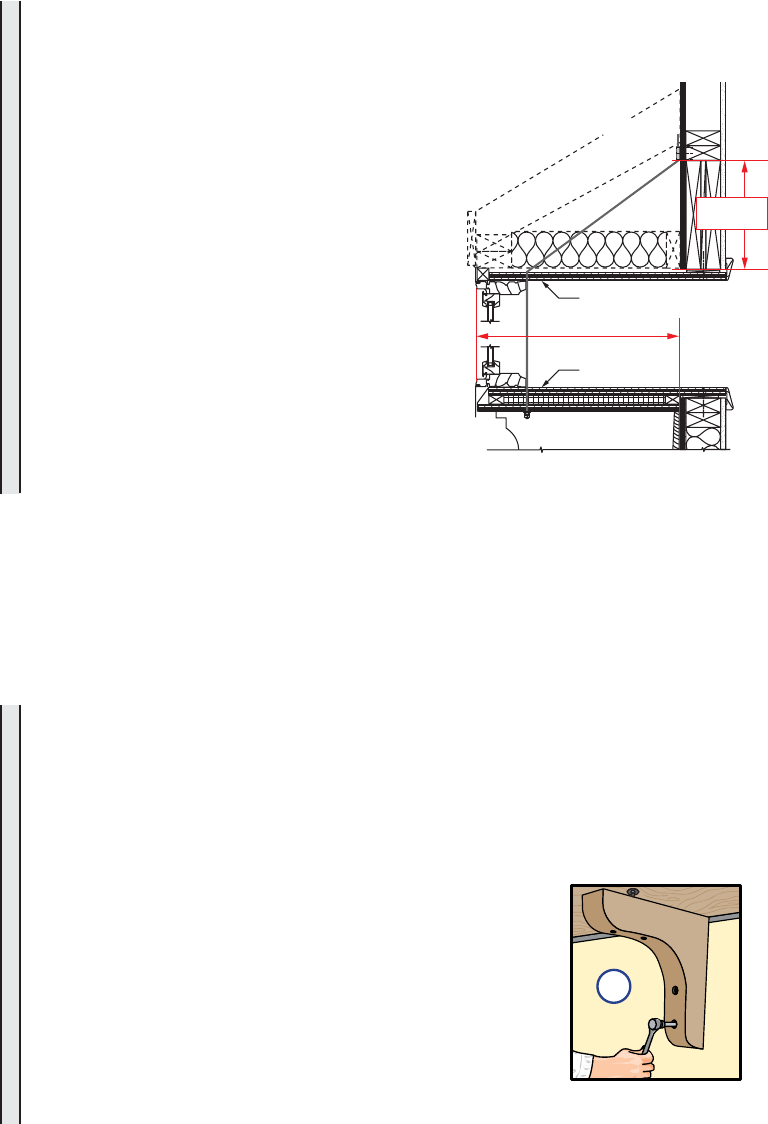

HEAD BOARD

SEAT BOARD

18" PROJECTION

MAXIMUM

DASHED LINES INDICATE

POSSIBLE CONSTRUCTION

FOR GABLE ROOF

MINIMUM

10-1/2”

HEADER MOUNT OF CABLE CLAMPS

is method may only be used if the projection of the bay/bow is 18" or less.

Use the Cross Bracing method if the projection of the bay/bow is more than 18".

Note: Be sure that the cable clamps are secured

to a solid structural member - header, sill plates

or wall stud. If the structural member or cable

clamps are not securely attached, they may

loosen during or after installation causing the

bay/bow unit to sag.

A. Install the cable clamps. Drive the #12 x 3-1/4"

square screws part way into the mounting surface

using a #3 square drive bit.

B. Run the cable up through the bottom of the

cable clamp. Hold the cable up tight above the

clamp and drive the two center clamp screws all

the way in to lock the cable in place. Drive in the

remaining #12 x 3-1/4" square screws all the way.

Note: Make sure all 4 screws are driven in at

maximum torque. Additional tensioning may

be done with the nuts on the opposite end of the

cable at the bottom of the window.

4E

ALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALL