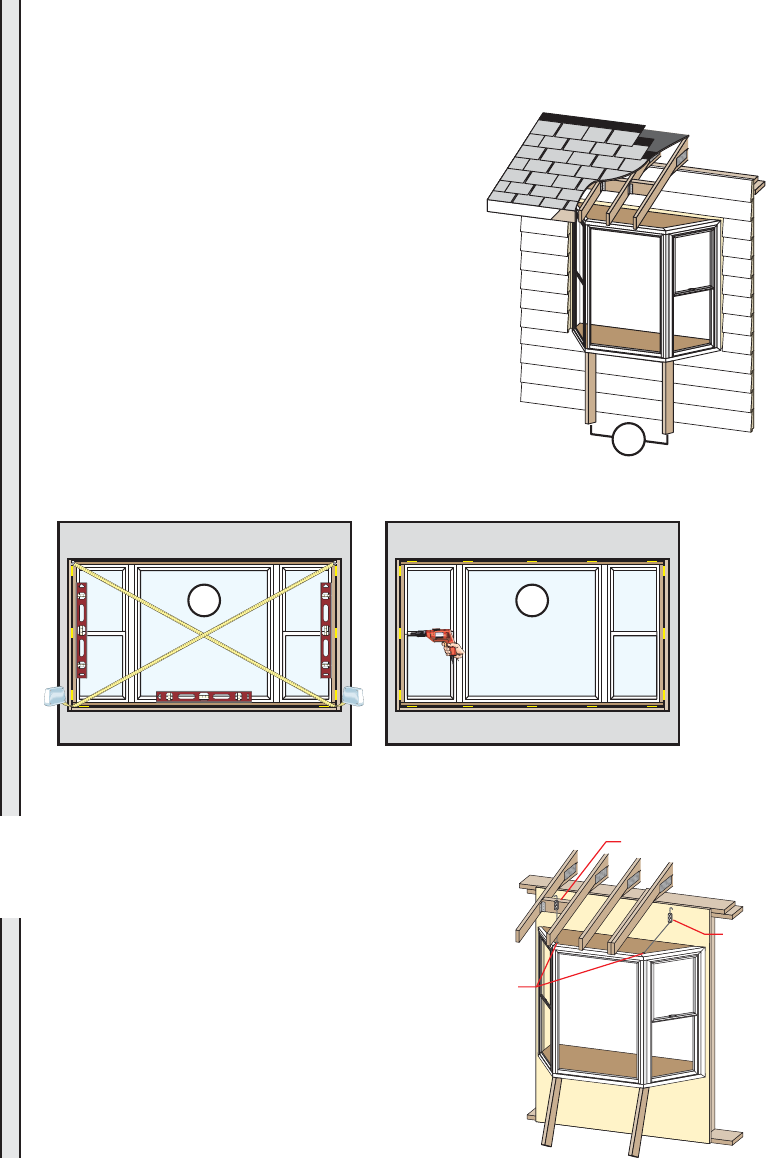

B. Insert the window from the exterior of the building. Place the seat of the window at the

bottom of the opening and slide the top into position. Center the window between the sides

of the opening to allow clearance for shimming.

TWO OR MORE PEOPLE WILL BE REQUIRED FOR THE FOLLOWING STEPS

2C

Note: If cross bracing is required for sot

installation of the cable systems, proceed to Step 3A

and install cross bracing before unit is inserted into

the rough opening.

C. Place temporary bracing under the seat of the

window to raise the unit level.

D. Place a shim near the top of the one jamb board,

aligned with the top pre-drilled hole in the jamb

board. Drill a pilot hole and partially insert a #10 x 3"

at head screw provided. Repeat for the other jamb.

E. Continue placing shims at each pre-drilled

installation screw hole in the jamb boards to plumb

and square the window. Check window for squareness

by making sure diagonal measurement for corner to

corner is within 1/8" in both directions. Insert a #10

x 3" at head wood screw into each pre-drilled hole in

the jamb boards. Finish inserting the top screw in each

jamb board.

2

PREPARING AND SETTING THE WINDOW (CONTINUED)

Interior

2E

Interior

2E

F. If desired, shim and fasten headboard to rough opening. To keep plywood straight, center

one nish head screw or 10D nish nail on units less than 10 feet wide and equally space two

fasteners on units wider than 10 feet.

3

CABLE CLAMP INSTALLATION

Install Cable Clamps based on type of installation

needed. Cross Bracing Installation consists of

attaching 2 x 6 cross bracing between the rafter

tails. Header Mount Installation consists of

attaching to a solid structural member - header,

sill plates or wall stud.

Note: Support cables are installed in factory

assembled bay and bow combinations.

Cross bracing mount

Header

mount

T-nut

ALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALLALL